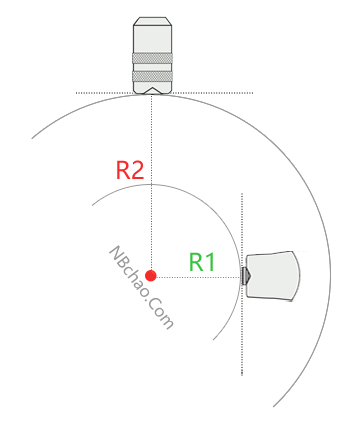

When choosing a coating Thickness Gauge, users should not only choose different measurement principles, measurement ranges and accuracy based on different substrates, but also consider the environment of the measured object from the actual situation. Especially for non-planar objects, most Thickness Gauges at home and abroad have clear regulations on the radius of curvature. In view of the fact that some Beichao users are vague about this, we have made a schematic diagram to illustrate how to choose a coating Thickness Gauge for measuring concave and convex surfaces such as steel pipes.

The key is to look at the radius of curvature of the object to be measured (I suggest you to Baidu about what is the radius of curvature, so I won’t repeat it here)

For ease of understanding, the northern and southern tides are described in a circular shape, and for objects such as ellipses, the radius of the inscribed circle itself is sufficient.

Taking Yuwen's EC-770 as an example, the minimum surface radius requirements are: convex 1.5mm, concave 25mm

That is to say, if it is to measure the outer wall, the smallest pipe that the instrument can measure is a pipe with a radius of not less than 1.5mm; if it is to measure the inner wall, the radius of the measured object must not be less than 25mm.

As shown in the figure on the right, under normal circumstances, the curved surface coating that can be measured by R1 is also suitable for the curved surface coating of R2. On the contrary, the curved surface coating that can be measured by R2 may not be suitable for smaller R1. Test object coating.

The curved surface radius requirements of the coating Thickness Gauge are generally related to the structure of the probe and the coating Thickness Gauge itself. The measurement of the inner wall paint film generally uses a "strip line" coating Thickness Gauge, and the outer wall paint film can be both.

The author suggests that although the price of the Thickness Gauge with wires will be more expensive, it will be applicable to more environments. If the budget is sufficient, it is recommended to buy a Thickness Gauge with wires.

Of course, this article only explains how to select the minimum surface radius of the Thickness Gauge. For the selection of the measurement principle, accuracy, probe structure, measurement range and even other measurement environments (such as underwater and corrosion), you can refer to North-South Tide other related technical articles.

As a professional direct sales mall in the field of paint coatings, we have also developed a related [ Coating Thickness Gauge Selector ] for users to choose, which is believed to be helpful to users who do not know how to choose such instruments.

Please indicate when reprinting: The original source is NBCHAO Mall www.nbchao.com