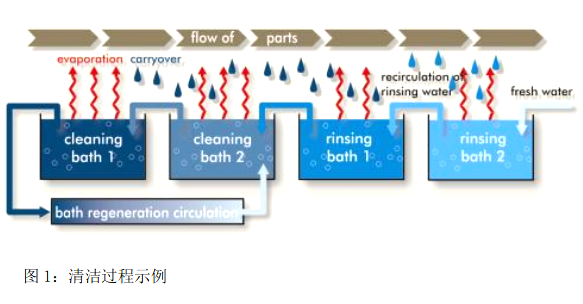

In the production of metal parts with special surface requirements, the reliability of pretreatment methods is the basis for high-quality products. The cleaning process is a required step in the shaping of finished products, surface preparation as well as surface coating. Insufficient cleaning of parts results in poor surface quality of the product, resulting in high costs. Cleaning of industrial and metal parts consists of a washing and rinsing program (Figure 1). First, the cleaning tank removes contaminants from the metal surface, followed by a rinsing tank to remove remaining contaminants and detergent residue. The temperature of the cleaning tank is 40-80°C. The evaporated water is generally replenished by the circulation system of the next pool.

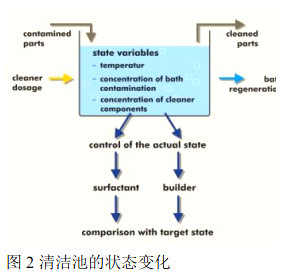

In order to ensure the high reliability of the cleaning process, the water cleaning process requires the parameters affecting the cleaning results to achieve a good and stable state. (as shown in Figure 2). These parameters include:

Concentration of detergent ingredients (boosters and surfactants)

Pollutants in the pool

pool temperature

Agitation of the bath

The main goal of process management is to continuously monitor the conditions of the cleaning tank and to control these conditions to the extent that a minimum amount of water, detergent and energy is used to ensure adequate cleaning quality.

The key here is to maintain the proper concentration of detergent ingredients (surfactants and boosters). Detergent ingredients, surfactants and boosters are consumed in varying degrees and each ingredient needs to be dosed appropriately. The concentration of detergent ingredients is constantly changing for various reasons. Examples include residue effects from parts, reduction of cleaning agent components (losses due to wash tank circulation) or differences in the number and degree of contamination of the workpieces each time.

Only by adjusting the amount of detergent in the cleaning tank or replacing the liquid in the cleaning tank according to the pollution degree and quantity of the workpiece and the condition of the cleaning tank during the cleaning process can the cleaning quality of the workpiece be guaranteed. Cleaning personnel and managers should cooperate with the cleaning agent manufacturer and equipment manufacturer. The required cleaning program parameters, as well as the concentration of the cleaning agent and its acceptable limit value, need to be set on the basis of personal experience, test operation data and optimized operation of laboratory or production equipment, so as to achieve the required cleaning quality. In reality, sometimes in order to ensure the cleaning ability, an excessive amount of detergent will be put into the cleaning pool, but the excessive amount of detergent will turn into pollutants and reduce the cleaning effect.

德累斯顿工业大学机电研究所和电子设计研究院分析了 清洁金属零件的过程,来帮助大家了解目前在行业中工序的应 用及技术状况。因此,咨询了大量的清洁过程管理者关于零件 的具体清洁任务及相应的过程管理。以下是 73 个不同公司的 专业人士提供的信息中总结出来,主要是欧洲汽车行业的清洁 过程:车身、动力总成及其原件、液压零件及其轴承等:

虽然清洁质量大部分都有定期的检测(74%),但主要是以 主观评判的方法,如目视检查,或后面工程的质量检查。

只有 23%的受访者通过客户方法检查清洁表面的干净程度。

只有 51%的受访者在与清洁剂生产商合作设定所需的清洁剂 浓度的参数。而 14%的受访者说清洁剂的浓度值是由清洁剂生 产商来决定。因此,可以说化学制剂生产商凭经验来决定清 洁池的称心状态。

在 84%的情况下,设备操作员控制着清洁剂的浓度。因此他也 负责优化当前的清洁工序。

78%的受访者要求检测促净剂的浓度,而其中 79%是滴定法进 行检测的。

只有 49%的受访者进行表面活性剂浓度的检测,而其中的 51% 采用表面张力仪来测量表面活性剂的浓度。

33%的受访者有一个清洁剂自动配料的系统,但其中只有 56% 的人认为他们的配量是更优的。

38%的受访者在考虑应用更好的方法,比如通过清洁池的监测 及清洁池液体的过滤或更换来实现清洁工序的优化。

分析表明,金属零件的清洁过程与其他生产过程〔如机 械加工)相比,并没有完全被掌握。尤其是清洗过程中有连 续控制输入(清洁剂、工件)和输出参数(更换液体,过滤), 以及中间过程参数,没法确保零件济洁质量稳定。零件清洁 的过程管理发展水平与过程可靠性要求有冲突,因为 83%的 人提到这个这个情况,详细地说是因为过程的不稳定性而带 来的损害赔偿。这个事实表明,83%的专业人士调查知道清 洁过程不足的后果。 有一个关于经济与环保的优化潜力的观点。本质的清 洗质量工艺参数(例如,清洁剂浓度及以消耗为导向的定 量)规定只发生在单一的情况下。为了实现清洗过程的高 可靠性,找到了显而易见的问题原因。在清洁过程中,大 量不同但是又相关联的参数,以及缺少成体系的配制剂及 一些个人经验概括。这些问题可以通过简单的过程参数的 帮助下用检测过程条件来得到解决。因此它需要一种可行 的测量技术,可以用于分析以及连续或分离的过程检测。

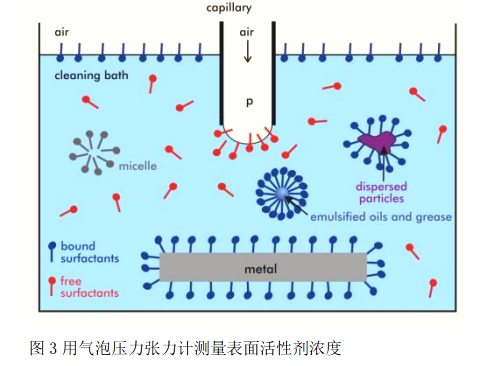

影响清洁能力的表面活性剂浓度可以通过测量动态表面张 力得到。另外可以通过测量导电率及使用酸碱滴定的方法来控 制促净剂的浓度。清洁剂浓度的连续检测可以According to消耗来确定 需要添加多少清洁剂。经济环保的优化清洁过程包括: 减少使用清洁剂的成本

避免漂洗池中清洁剂成分的积聚 延长清洁池的寿命

减少水及水污染处理成本 由于可以测得表面张力的参数,使表面活性剂浓度的检测 以及According to消耗来定量变为可能。

因此,气泡压力法表面张力仪 可用来测量有效的表面活性剂的浓度,如图 3.有效的表面活性 剂是没有被油和污染物束缚的,也没有附在金属表面。在清洁 过程中,只有这些自由的表面活性剂才是有效的,可以形成胶 束来去除金属表面的污染和油。

用测量清洁过程中液体的表面张力来检测有效表面活 性剂的浓度,使适当地使用表面活性剂成为可能。需要添 加额外的剂量时可使用测量结果来验证。为了将检测程序 可视化,图 4 显示出了在一个清洁池内连续测量的结果。 在开始准备时,首先可以看到水的表面力值(72.8 mN/m,温 度是 20℃)。当添加表面活性剂时,表面张力减低。

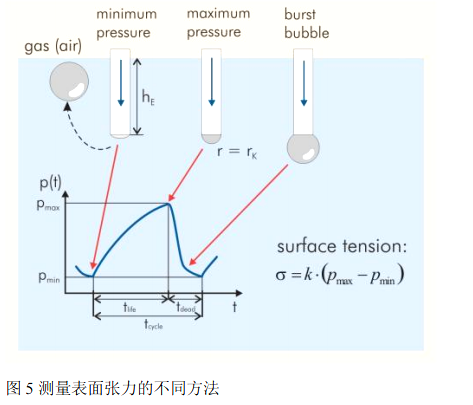

SITA 表面张力仪测量表面张力是以差压法为基础的。 在测试过程中,气泡通过插入液面下的毛细管中形成(如图 5),有一个特殊的传感器测量气泡毛细管顶端的压力。动 态表面张力是用最大和最小气泡压力差来计算,并使用校 准系数 K 来表示。

气泡压力用纯净水校准张力。标准系数 K 取决于自动 测量器具,不依赖气泡的寿命。SITA 差压法的设计原理大 大简化了表面张力仪操作,因为测量不再依赖于毛细管浸 入液体中的深度。

技术文件

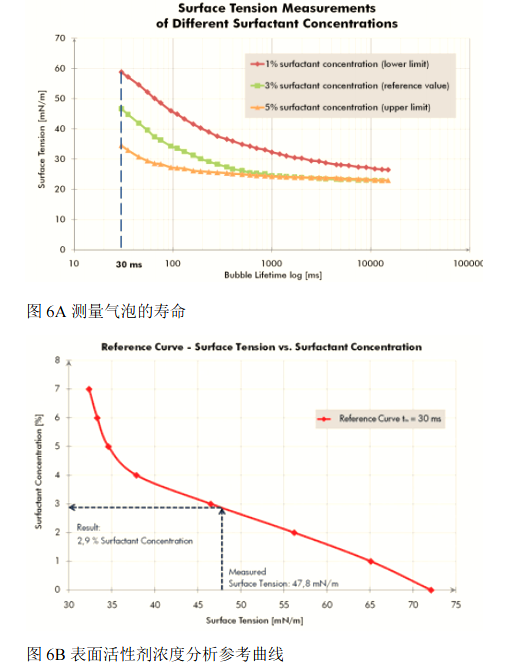

相对于静态方法测量表面张力,动态测量方法可以测量表 面的表面活性剂的浓度高于临界胶束浓度(CMC),即工业清洗过 程中经常使用的浓度范围,静态表面张力仪是无法测出超出 CMC 值的表面活性剂浓度。测量的基础原理是表面活性浓度与表面 张力过程值之间的量化关系。

动态表面张力取决于一个新形成的界面寿命。动态表面张 力的差异在于不同界面寿命(气泡寿命,如图 5)时有不同数量的 表面活性剂迁移到新的界面上。用哪个气泡寿命作为很好的测量 点只需以下程序测量一次就可以得知。在 SITA 表面张力仪的 Auto 模式下测量某种特定的已知表面活性剂浓度的液体。很好的 的气泡寿命值就是在表面张力测量值差额最大的那点(如图 6)。 之后,测出一系列已知的表面活性剂浓度不同的参照样本作为 参考曲线。这样,According to测出的表面张力值就可以在参考曲线中 查过表面活性剂的浓度了。

对于需要确保高可靠性的清洁过程,表面活性剂的浓度要 保持在特定的界限值内。

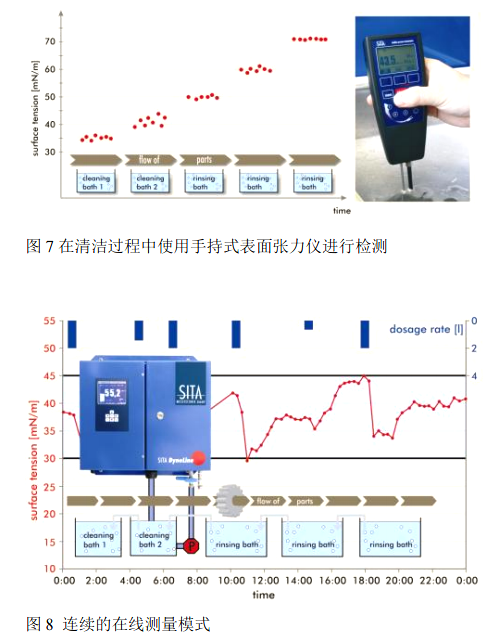

设定了清洁池的的特定表面张力范围后,用表面张力仪定 期的测量或者连续监测,以用来分析以及监测表面活性剂在整 个清洁过程的浓度。为了实现在过程或实验室中的有效测量, 测量仪器需要是可靠的,快速的且易于操作的。手持式张力仪 SITA DynoTester 可以实现这些要求。清洗液的表面张力跟温度 的测量只要按一个按钮,几十秒内即可得出结果。而气泡寿命 参数或平均测量数,都是预设的,并只能在管理模式下改变。 这些特性尽可能地减少操作错误的风险。 测量结果可以被保存在 25 个存储空间供后续评价。内置电 源可以使用高达 10 小时,确保高灵活性。在不均匀的液体中, 可选择多次读数自动取平均值的方法增加测量的可靠性。因此, SITA DynoTester是测量表面张力过程参数的一个新的经济的选择。

图 7 显示定期测量一个工厂清洁池的结果。表面张力值的 简图显示了在稳定条件范围内的清洁过程的寿命。在最后一个 漂洗池,表面张力达到跟水一样的值。这说明表面活性剂浓度 减少到 0。

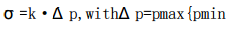

连续的清洁池表面张力监测可以通过清洁池的支线管道来 确保被测量的液体能代表清洁池实际情况。在支线管道内被连 续测量的样本需要是均质的,而且要保持一个同样的温度水平。 仪器内在毛细管附近有一个特殊的,可允许缓慢流动的容器能够将对气泡的消极影响减少到最低而且可以避免颗粒堆积。流 动的速度是 2 升/分钟,这确保了样本达到足够的均质而且不会 反乳化,并且接近清洁池的温度水平。

A critical issue is the lifetime of the capillary. During use, accumulation of constituents in the cleaning bath can alter the characteristics of the capillary. The SITAg tensiometer uses a capillary made of a stronger, less water-wettable PEEK resin instead of an ordinary glass capillary to measure bubble pressure. The PEEK material and the gradually increasing diameter of the capillary ends minimize capillary effects. This means that it is difficult for liquid to enter the inside of the capillary (to reduce the residue of liquid wetting inside the capillary and affecting the next measurement). Under the same conditions, a traditional laboratory capillary has a lifetime of about 300 hours, while the optimized PEEK capillary lifetime is more than 10 times that. This design avoids particle accumulation and ensures long-term reproducibility of bubbles.

SITA DynoLine online measurement technology is used to monitor the continuous cleaning tank. This fully automatic equipment can be combined as part of a factory production line, adapted to the specific needs of processing and chemical plants. It differs from other sensors and traditional surface tension testing techniques in that the SITA DynoLine can automatically control the sample provided, the calibration water and the automatic cleaning program. Other essential features include self-monitoring functions, error detection and signaling for trouble-free operation. Due to its own periodic detection function, any changes in the capillary characteristics (eg contamination by a particle build-up) can be recognized by the measuring instrument itself.

To control the fluid, the device has a stopcock between the sample and the water, and it has a pressure sensor to monitor the incoming pressure. All measured values can be stored in the device for one year to record the measurement results. The surface tension measurement results of the equipment can be output to other equipment or control systems through the interface, so that the equipment for supplementing surfactant can work automatically, and the cleaning pool can maintain a good range of surfactant concentration (as shown in Figure 8).

In many surface treatment applications, from car bodies to precision parts such as pumps and bearings, the cleaning process is successfully optimized by detecting and quantifying detergent components (surfactants and self-detergency builders). Moreover, a consistent and high cleaning quality can be achieved with a minimum of water, detergent and energy.