Wet Film Overview

Coating thickness is an important index that needs to be controlled in coating construction. Whether the coating thickness is controlled reasonably will directly affect other properties of the coating.

In the anti-corrosion mechanism of the coating, its shielding effect is the most important factor, and the shielding effect of the coating is closely related to the thickness of the coating. In addition, in terms of performance comparison of various coating products, it is only comparable under the same coating thickness, such as coating adhesion, impact strength, flexibility, etc. Different thicknesses have different test results. .

In the process of coating construction, it is also required to control the appropriate thickness of the coating, otherwise it will affect the appearance quality of the coating,

Coating thickness measurement can be divided into wet film thickness measurement and dry film thickness measurement.

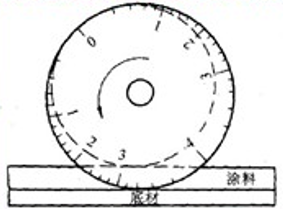

The principle of wet film wheel

There is a third surface in the middle of the two surfaces on the same horizontal plane. When the two outer surfaces are pressed against the bottom plate under the wet film, the third surface is perpendicular to the surface of the wet film. Because the third surface has a height from the two outer surfaces Poor, during the measurement, the wet film thickness is the point at which the third surface first contacts the wet film surface.

There is a third surface in the middle of the two surfaces on the same horizontal plane. When the two outer surfaces are pressed against the bottom plate under the wet film, the third surface is perpendicular to the surface of the wet film. Because the third surface has a height from the two outer surfaces Poor, during the measurement, the wet film thickness is the point at which the third surface first contacts the wet film surface.

The disc type wet Film Thickness Gauge is composed of an eccentric wheel supported by two concentric wheels. The left and right symmetrical scales are engraved on the concentric wheels. When the Thickness Gauge is rolled on the paint film, the gap between the wet film and the eccentric wheel The gap changes. The paint film first touches a point on the center wheel, and the scale on the concentric wheel corresponding to this point is the thickness of the paint film at that point.

Instructions for use of wet film wheel

When measuring, place the Thickness Gauge on the wet film so that the minimum reading is at the top and the maximum gap between the eccentric wheel and the paint film is just above the wet film. Let the Thickness Gauge roll half a circle in the direction of the minimum scale of the Thickness Gauge on the paint film, and repeat the half circle in the opposite direction, and read the readings at the first contact point between the wet film and the eccentric wheel when rolling in two directions, and the average value is the test result.

When using the instrument, it needs to be perpendicular to the surface to be measured, otherwise the correct result will not be obtained;

If the rolling of the instrument on the surface starts from zero, the test result will have a certain error due to the extrusion of the coating film

The measurement of wet film thickness is inaccurate. The final coating thickness of the product should be determined by measuring its dry film thickness. However, by measuring the wet film thickness, the dry film thickness can be roughly estimated to avoid excessive errors.

The corresponding relationship between wet film thickness and dry film thickness varies with the type of coating and the viscosity of the application.