High-shear dispersion emulsification is the process of effectively, rapidly and uniformly transferring one phase or multiple phases (liquid, solid, gas) into another immiscible continuous phase (usually liquid). In general, the phases are immiscible with each other. When external energy is input, the two materials recombine into a homogeneous phase. Due to the high tangential speed generated by the high-speed rotation of the rotor and the strong kinetic energy brought by the high-frequency mechanical effect, the material is subjected to strong mechanical and hydraulic shearing, centrifugal extrusion, liquid layer friction, and impact in the narrow gap between the stator and the rotor. The combined effects of tearing and turbulence form suspensions (solid/liquid), emulsions (liquid/liquid) and foams (gas/liquid). So that the immiscible solid phase, liquid phase, and gas phase are uniformly and finely dispersed and emulsified in an instant under the combined action of corresponding mature technology and appropriate amount of additives. After high-frequency cycles, stable high-quality products are finally obtained.

The pipeline type high-shear emulsifier consists of 1-3 working chambers. Driven by the high-speed motor, the material moves at high speed in the narrow gap between the rotor and the stator, forming turbulent flow. The material is subjected to stronger hydraulic shearing, The comprehensive effects of centrifugal extrusion, high-speed cutting, impact and grinding can achieve the effects of dispersion, emulsification and crushing. The processed material itself, its physical properties, the number of working chambers and the time for controlling the residence time of materials in the working chamber determine the particle size distribution range, the effect of homogenization and refinement, and the size of the output.

| ◆ Large processing capacity, suitable for industrial online continuous production; ◆ Narrow particle size distribution range, high uniformity; ◆ Time-saving, effective, and energy-saving ; Ensure low noise and stable operation of the whole machine; ◆ Eliminate quality differences between batches of production; ◆ No dead angle, 100% of materials are crushed, dispersed and sheared; ◆ Has short-distance, low-lift conveying function; ◆ Easy to use and easy to maintain; ◆ Automatic control can be realized; ◆ Cartridge mechanical seal ensures no leakage of materials; ◆ Stand-alone processing capacity is from 1 to 120m3/h. |

|

Pipeline high shear working process

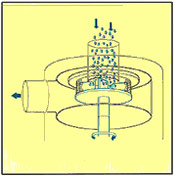

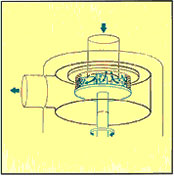

| 1. Under the action of the centrifugal force generated by the high-speed rotating rotor, the materials in the picture are sucked into the working chamber from the upper feeding area of the working head at the same time from the axial direction. | 2. The strong centrifugal force throws the material into the narrow and precise gap between the stator and the rotor from the radial direction. At the same time, it is subject to centrifugal extrusion, impact and other forces, so that the material is initially dispersed and emulsified. | 3. At the outer end of the high-speed rotating rotor, a linear velocity of at least 15m/s, up to 40m/s is generated, and strong mechanical and hydraulic shearing, liquid layer friction, and impact tearing are formed to fully disperse the material , emulsification, homogenization, crushing, and spraying out from the radial direction at the same time. Dispersion, emulsification and homogenization are finally completed after one-time treatment or recycling treatment. |

|

|

|

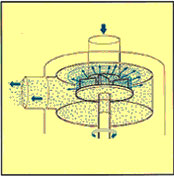

4 Or under the action of the centrifugal force of the second group of rotors, enter the second working area of the stator and rotor; once again go through the stator and rotor multi-layer, intensive and uniform shearing action, and then spray out from the radial direction, in the third group Under the action of the centrifugal force of the rotor, it enters the third set of stator and rotor working areas to complete the processes of dispersion, emulsification, and homogenization. After three groups of stators and rotors are processed sequentially, the materials are uniformly processed in the shortest time, and the process of dispersion, emulsification and homogenization is finally completed.