Coatings have a long history of application, a wide range of applications, and nearly a thousand varieties. According to the habit formed for a long time, there are several classification methods as follows.

① Classification by coating form

Divided into solvent-based coatings, high-solid coatings, water-based coatings, non-water-dispersed coatings and powder coatings. Among them, the non-water-dispersible paint is similar to the latex paint, the difference is that the latex paint uses water as the dispersion medium, and the resin is dispersed in water by the action of an emulsifier to form an emulsion of oil/water structure, while the non-water-dispersible paint is based on aliphatic hydrocarbons. Dispersion medium to form oil/oil emulsions. High solids coatings are usually coatings with a solids content higher than 7o%.

②Classification by coating application

Divided into architectural coatings, industrial coatings and maintenance coatings. Industrial coatings include automotive coatings, marine coatings, aircraft coatings, wood coatings, leather coatings, paper coatings, coil coatings, plastic coatings and other industrial coatings. Coil coatings are coatings for the production of pre-coated coils. Pre-coated coils are organic materials/metal sheets that are sold in rolls or sheets after the coiled metal sheets are coated with paint or laminated with plastic film. It is also known as organic coated steel plate, color steel plate, plastic composite steel plate, etc. It can be directly processed and formed without painting. Pre-coated coils are mainly used for roofs or walls of buildings.

③Classified according to coating function

There are antirust paint, anticorrosion paint, insulating paint, antifouling paint, high temperature resistant paint, conductive paint, etc. Paints in the coatings industry are mainly two types: primers and topcoats. The primer focuses on firm adhesion and good anti-corrosion protection; the top coat focuses on decoration and outdoor protection. The two are used together to form a solid coating, but there are significant differences in their composition. The topcoat should have good decorative and protective functions. The top coat is often referred to as enamel (also called enamel paint). Pigments with good light resistance and coloring are used in enamel paint. The paint film is usually flat and smooth, tough and wear-resistant, just like porcelain.

④ Classification by construction method

There are spray paint, dipping paint, electrophoretic paint, baking paint, etc. Spray paint is paint applied with a Spray Gun.

Dip varnish is to put the workpiece into the paint container and paint it on the rattan. Water-soluble paints constructed by electrophoresis are called electrophoretic paints. Baking varnish refers to the paint variety that needs to be baked at a certain temperature to dry and form a film, especially the variety composed of two or more film-forming substances, which does not react at room temperature, and only after baking can the intermolecular The functional groups undergo a cross-linking reaction for film formation.

⑤ Classified according to film-forming mechanism

There are conversion coatings and non-conversion coatings. Non-conversion coatings are thermoplastic coatings, including volatile coatings, thermoplastic powder coatings, latex paints, etc. Conversion coatings include air-drying coatings, curing agent-cured and dried coatings, bake-cured coatings, and radiation-cured coatings. Air-drying means that the paint will dry by itself when it reacts with oxygen or moisture in the air at room temperature after painting.

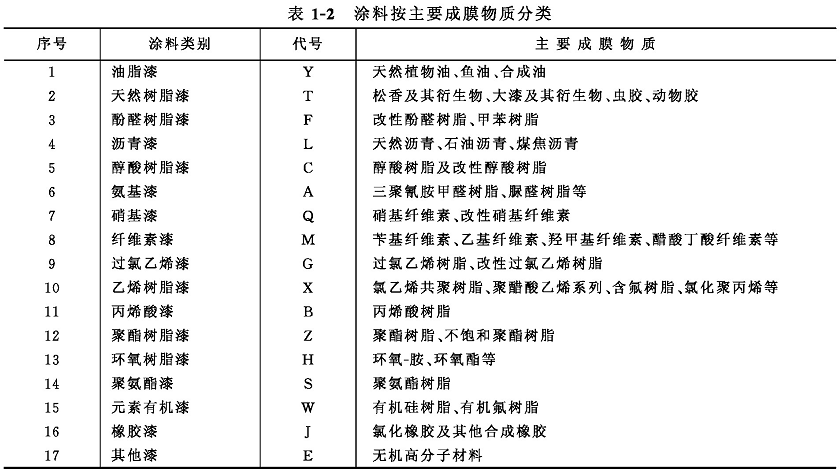

⑥Classified by main film-forming substances

According to the coating classification method promulgated by the former Ministry of Chemical Industry, it is divided into 17 categories according to the main film-forming substances (see Table 1-2). The classification method is mainly introduced below.