In order to obtain an economical and effective dispersion method, the production process of pigmented paint usually adopts 4 steps.

① Pre-dispersion The pigment is mixed with part of the paint in the equipment with a stirrer to prepare a semi-finished color paste, referred to as the paste.

② Grinding and dispersion Disperse the mixing slurry through various grinding equipment to obtain pigment paste.

③ Paint mixing In the paint mixing tank with agitator, add the remaining paint and other additives and solvents to the pigment paste, and adjust the color if necessary to meet the quality requirements of the color paint.

④Purification packaging: Remove mechanical impurities and coarse particles through different filtering equipment, and then pack into finished products.

The production of colored paints was mainly intermittent in the past, and now continuous production has appeared. Equipment adapted to continuous production, especially grinding and dispersing equipment, has developed rapidly in recent years. The production process of color paint is generally divided according to the grinding and dispersing equipment used, and the commonly used ones are sand milling dispersion process, roller milling dispersion process and ball milling dispersion process. The production of colored paint usually forms a professional production line according to the type of production to avoid interference between different types.

There are three stages in the manufacture and use of pigment dispersions: ① pre-mixing, that is, mixing dry pigments into the paint and eliminating agglomerates; ② applying sufficient shear stress to separate pigment aggregates; ③ thinning paint, that is, mixing pigment dispersions with The remaining components of the formula are mixed to form the paint.

Decentralized equipment

Pre-mixing is mainly for mixing and plays the role of coarse dispersion. In the past, the grinding and dispersing equipment of colored paint was mainly roller mill, and the pre-mixing equipment matched with it was various types of pulpers. In recent years, sand mills are the main grinding and dispersing equipment, and high-speed dispersing machines are also used as supporting equipment. This is the most widely used pre-dispersing equipment at present.

Rotate after lifting, so a high-speed disperser can be used with 2~4 fixed containers in turn. The fuselage of the high-speed disperser is equipped with hydraulic lifting and turning devices. The hydraulic lifting device is provided with pressure by the gear oil pump to make the machine head rise, and it depends on its own weight when it descends, and the descending speed is controlled by the stroke throttle valve. The swivel device can turn the machine head 360°.

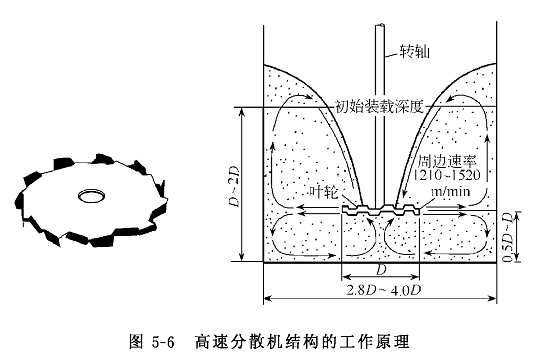

The key component of the high-speed disperser is the serrated disc impeller. The high-speed rotation of the impeller makes the slurry in the mixing tank present a rolling circulation and generate a large vortex. The pigment particles, located at the top of the millbase, quickly spiral down to the bottom of the vortex. At 2.5~5cm from the edge of the impeller, a turbulent zone is formed. In this area, the pigment particles are subject to strong shear and impact, so that they are quickly dispersed into the paint paste. Outside this area, upper and lower streams are formed to fully circulate and turn the millbase. As shown in Figure 5-6.

In the initial stage of the operation of the high-speed disperser, the pigment is still piled on the paint. At this time, after mixing at a low speed, the speed is increased, and the peripheral speed of the impeller

Satisfactory dispersion effect can only be obtained when it needs to reach more than about 20m/s. However, the rotating speed should not be too high, otherwise it will cause splashing of paint paste and excessive exposure of the disc impeller to mix with air, which will increase power consumption. The maximum peripheral speed of the general impeller is about 25~30m/s. The dispersion phase takes about 15 min. After reducing the speed, put in the remaining formula components to dilute the finished paint. When producing latex paint, latex cannot enter the dispersion stage, because most latex will gel when subjected to high shear, and should be added in the low-speed thinning paint stage.

In order to achieve laminar flow in the lower area of the impeller, on the one hand, the peripheral speed of the impeller should not be excessively increased, on the other hand, the viscosity of the paint slurry should be appropriately increased, and the position of the impeller should be lowered. To obtain laminar flow, the minimum viscosity is generally above 3Pa·s . The higher the viscosity, the greater the shear stress exerted on the aggregate and thus the faster the dispersion. The viscosity should be set at the peak power of the motor.

In order to be as effective as possible, the amount of pigment should be increased as much as possible. As long as the solvent-based coating can be dispersed and stable without flocculation, the resin content in the base material used should be as small as possible. The Daniel Pour Point can be used to estimate the resin/solvent ratio, and then determine the paint-to-pigment ratio at the peak amperage of the motor to have an appropriate viscosity at high shear rates. For the dispersion of latex paint pigments in water, water-soluble polymers are often added to increase the viscosity during dispersion.

When the high-speed disperser is in use, the centrifugal force pushes the material to the side of the tank. If the grinding material is a Newtonian fluid, the size and operating conditions are appropriate, the entire material is uniformly mixed and repeatedly passes through the highest shear zone near the edge of the disk. But if the abrasive is shear-thinned, the upper end of the material on the edge of the groove has a high viscosity due to low shear, and it sticks to the wall, making the mixing incomplete. Some abrasives contain pigments that shear thin the final coating. To solve the problem of wall sticking, the pigments that give the shear thinning effect can be added slowly after separation. A good way to reduce the problem of wall sticking is to have a slow-speed scraper rotate along the upper part of the inner wall of the tank in the dispersion tank, while a high-speed disc rotates rapidly in the center of the tank.

Compared with other dispersing equipment, the high-speed dispersing machine has the lowest investment and operating costs, no additional pre-mixing is required, the thinning and finishing of paint can be completed in the same tank, the color change and cleaning are also more convenient, and the use of a covered tank has low solvent loss; The main disadvantage is that the shear stress applied to the pigment aggregate is low, so it can only be used for pigments that are easy to separate.