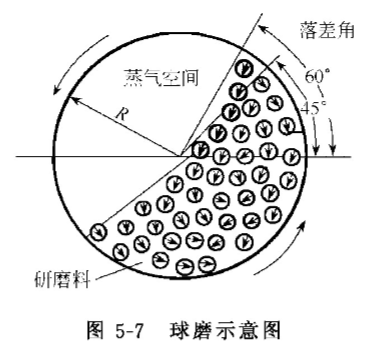

A ball mill is a cylindrical container, mounted horizontally, partially loaded with steel balls or pebbles. After adding the components of the grinding material into the ball mill, the ball is lifted on one side when rotating, and then rolled down to the lower side like a waterfall, as shown in Figure 5-7. As the balls roll past each other through the thin layer of abrasive between them, intense shear and impact are exerted on the pigment aggregates.

There are two types of ball mills: steel ball mill and stone ball mill. The balls and lining of the steel ball mill are all steel, and the balls and lining of the stone ball mill are all ceramic. The advantage of the steel ball is that it has a high density, so the shear is also large, and the running time is short, but some wear, such as dispersing TiO2 in the steel ball mill, the product will be gray instead of white.

The dispersion primer is sometimes ground with a steel ball, and the primer is generally gray. Use a stone ball mill when discoloration is an issue.

Ball mills with larger diameters are more efficient because the balls have a longer path to roll down. The operating efficiency depends on the filling, the ball should be filled to half full, which can give the longest rolling distance. The grinding material should just cover the balls when the ball mill is stationary, and fill the gaps between the balls. If you add too much, the grinding time will need to be extended. The diameter of the ball is the same, and the volume of the ball accounts for about 32% of the total volume of the ball mill when it is half full. The volume of the abrasive is slightly greater than 18% at good efficiency. If the diameter of the ball is different, the packing coefficient is large, and there is less space for the abrasive.

The dispersion efficiency of the ball mill depends on the movement form of the ball, and it is hoped to form the waterfall shown in Figure 5-7. Under normal circumstances, the cascade angle of the ball is 45°. For difficult-to-disperse pigments, the speed can be increased appropriately, and the cascade angle can reach 6o°, which improves the dispersion efficiency. If the speed is too fast, the waterfall angle of the ball exceeds 6°, and the ball falls instead of rolling down in a waterfall, which reduces shear and causes damage to the ball. If the speed is faster, the ball will exert less dispersion due to centrifugal action (running against the wall). Whether the ball mill is in an effective state of motion can be judged from the running noise. If the noise is too loud, it means that the ball is thrown out of the paint paste; if the ball is not lifted enough or the paint paste viscosity is too high, the speed is too high, and the ball and paint paste are attached to the wall, there is almost no sound.

Grinding efficiency is also affected by the viscosity of the abrasive. If the viscosity is too low, the ball will wear out severely; if the viscosity is too high, the ball will roll slowly and the efficiency will decrease. Good viscosity depends on the size and density of the balls. The larger the ball and the higher the density, the better the viscosity. The viscosity is usually around 1Pa·s.

The time required to achieve a satisfactory separation depends on the ease with which the aggregates are separated. Usually at least 6~8h, even for difficult to separate pigments will not exceed 24h. If it takes 72 hours or longer, it should be caused by poor formula or incorrect ball mill filling.

Although the investment of the ball mill is high, the operating cost is low, no pre-mixing is required, and no maintenance is required during operation. Sometimes, the thinning of the lacquer is carried out in the ball mill, of course, it is generally carried out separately. There is no volatilization loss during the operation of the ball mill, except for the most difficult to separate pigments, the ball mill can disperse. The ball mill is not easy to clean, so it is suitable to make only one kind of dispersion, that is, throw the next material as soon as it is clear, without cleaning. If you want to prepare a series of colors in the same ball mill, you should start with the lightest and work your way up to the darkest. Another difficulty of ball milling is that the feeding amount cannot be changed.

After the ball mill is discharged, a considerable amount remains in the mill, which needs to be cleaned, and the cleaned material can be added to the next batch of materials. The solvent cannot be used alone for cleaning. If the concentration of the resin solution in the grinding base is slightly higher than the minimum point of the Daniel flow point curve, the addition of solvent will cause the dispersion to flocculate. Therefore, the concentration of the resin solution used in the grinding base should not be lower than that used in the grinding base. .

Laboratory ball milling is not directly related to production ball milling because the efficiency of ball milling is related to its diameter. The diameter of the ball mill for production is 1.25~2.5m. The diameter of the porcelain pot Grinder used in the laboratory is generally less than 30cm, and the speed is generally lower than that required by Xinxin. It correlates poorly with production ball mills. The laboratory Quikee mill is more suitable, disperses faster, and is roughly similar to the production ball mill. This is a steel container, half filled with 30mm steel balls, add enough abrasive, slightly more than to cover the steel balls. Then vibrate on a paint vibrating machine. It takes 5-10 minutes for easy-to-separate pigments, and 1 hour for difficult-to-separate pigments. Porcelain jars and glass beads, sand or porcelain beads can also be used where steel beads will affect the color.