Gloss is the ability of a coated surface to reflect rays of light transmitted on it in one direction. The higher the reflectance, the higher the gloss. Coat gloss is a major performance indicator for identifying coating appearance mass. Glossiness can be classified according to different conditions. Different products have different requirements for coating glossiness. For example, for high-end cars, the higher the coating glossiness, the better, while some opticalin struments, military equipment and ground camouflage facilities require flat light and no coating gloss. According to the level of its glossiness, it can be divided into high gloss, semi-light or medium gloss, etc. The gloss range is shown in the table below.

| distinguish | High gloss | half-gloss | eggshell-gloss | flat-gloss | no-gloss |

| gloss(%) | >70 | 30-70 | 6-30 | 2-6 | <2 |

Note: The gloss classification in the table above is based on the gloss measured at 60 ° gloss

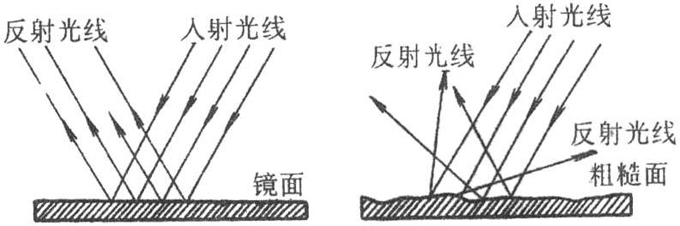

Coating gloss is not only related to the coating used, but also to the construction mass of the painting. Properly constructed coating surfaces are relatively flat and smooth, with high reflectance to ray of light, while coarser coating surfaces with sagging, pinholing, orange grain and adhered impurities have lower reflectance to ray of light, see Figure 1.

Figure 1 Schematic diagram of light reflection on different surfaces

The measurement of coating glossiness is generally carried out using a gloss meter, and the result is expressed as a percentage of the ratio of the amount of positively reflected light from the coated surface to the amount of positively reflected light from the standard surface under the same conditions. Therefore, coating gloss generally refers to the relative comparison value with the standard plate gloss.

According to the different shooting angles of the gloss meter light source, it can be divided into fixed angle gloss meters (such as 45 °, 60 °), multi-angle gloss meters (such as 0 °, 20 °, 45 °, 60 °) and variable angle gloss meters (can be measured between 20 ° -85 °). For high gloss coating (60 ° gloss is higher than 70%), a gloss meter with a human shooting angle of 20 ° should be used, and for low gloss coating (60 ° gloss is lower than 30%), a gloss meter with a human shooting angle of 85 ° should be used, which can make the test results more accurate.