The thickness of the coating reflects the wear resistance and corrosion resistance of the product surface to a certain extent. The measurement of the coating thickness is often used as a preliminary test to judge the surface performance and is widely used. There are many methods for measuring coating thickness, including magnetic method and eddy current method, but in view of economic cost conditions, magnetic method and eddy current method are more often used in surface engineering. But both are different in application and principle. Now compare the two so that users can make a better selection.

1. Measuring principle of magnetic method and eddy current method

According to the records in the document "Characteristics and Applications of Magnetic and Eddy Current Thickness Gauge" published by Peng Xuelian, the principles of the magnetic method and the eddy current method are as follows:

(1) Measuring principle of magnetic method

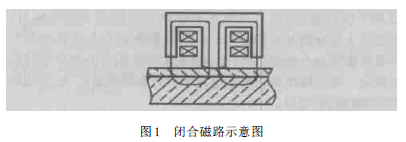

When the probe is in contact with the covering layer, the magnetic head of the measuring head and the magnetic metal substrate form a closed magnetic circuit. Due to the existence of the non-magnetic covering layer, the reluctance of the magnetic circuit changes, resulting in a change in the magnetic flux. Generally, the thicker the coating, the smaller the magnetic flux and the smaller the induced electromotive force. By measuring its change, the thickness of the coating can be derived. The schematic diagram of the closed magnetic circuit is shown in Figure 1.

(2) Measuring principle of eddy current method

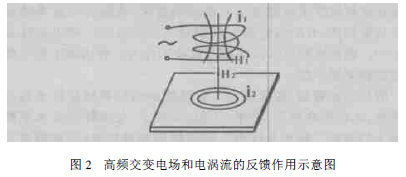

A high-frequency alternating electric field is generated in the coil of the probe by using a high-frequency cross-edge current. When the probe is in contact with the coating, the conductor under the probe generates an eddy current, which generates feedback to the coil in the probe, and the thickness of the coating can be derived by measuring the magnitude of the feedback. The feedback effect of high-frequency alternating electric field and eddy current is shown in Figure 2. Its amplitude and phase are functions of the thickness of the non-conductive covering between the conductor and the probe.

2. Application of magnetic method and eddy current method

(1) The Thickness Gauge of the magnetic method is mainly used to measure the thickness of the non-magnetic coating on the magnetic metal substrate;

(2) The Thickness Gauge of the eddy current method is mainly used to measure the thickness of the non-conductive coating on the non-magnetic metal substrate.

Taking the Thickness Gauge of Divers high as an example, the Thickness Gauge measurement methods of F-type probe and N-type probe are magnetic method and eddy current method respectively.