Paint (as shown in Figure 1) is a viscous liquid that is coated on the surface of an object to be protected or decorated, and can form a continuous film firmly attached to the object, usually based on resin, or oil, or emulsion, adding Or do not add pigments, fillers, add corresponding additives, and prepare with organic solvents or water. During the production process of paint, it is easy to produce color difference due to raw materials and other reasons. More and more manufacturers decide to use precision measuring instruments to detect paint color difference in order to strictly control the quality of paint.

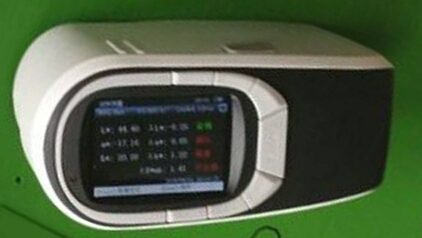

A chemical company in Dongguan, after learning that the CS-580 Spectrophotometer of Hangzhou Caipu Technology (as shown in Figure 2) can solve the problem of paint color difference measurement and quality inspection, invited Caipu professionals to the factory to directly demonstrate how to use CS-580 to measure the color of paint. The company has a personalized management team, excellent engineering and technical team, professional coloring technicians, good after-sales service, pays special attention to scientific and technological innovation and strengthen management, always puts the research and development and production of high-tech products in the first place, and thinks about customers. Think, create what customers need. In order to improve product quality and strictly control the quality inspection, the company seeks to use color spectrum Spectrophotometer to detect color difference.

Figure 2 - Color Spectrum CS-580 Spectrophotometer

For the convenience of measurement, the manufacturer adopts the method of directly measuring the sprayed parts after spraying the paint.

The specific measurement process is as follows:

Step 1: Prepare the sample of the sprayed part to be tested (as shown in Figure 3);

Figure 3 - Painted parts to be tested

Step 2: Turn on the instrument, set various parameters and formulas according to the instructions, and perform black and white calibration;

Step 3: After the black-and-white calibration is completed, press the "Print" button to position the measurement area first, align the standard sample to be tested with the test hole, and be careful not to leak light so as not to affect the test result, then press the "Test" button, and a "beep" sound After the measurement is completed, view the test results;

Step 4: After the above standard sample measurement is completed and saved, press the "Menu" button to enter the "Sample Measurement" interface under the standard sample, align the sample with the test hole according to the method of standard sample measurement, and press Press "Test" to measure, and after the "beep" sound, the color difference measurement is completed, and the measurement result can be obtained (as shown in Figure 4).

Figure 4 - Measurement Results

After the measurement is completed, through the above simple operations, the Spectrophotometer CS-580 of Color Spectrum Technology can intuitively display the Lab value of the measured sample and the color difference between different samples. The customer is very satisfied with the test results and bought the instrument on the spot. The company introduces international high-end technology, adopts professional production equipment and high-quality raw materials from Japan, Korea, the United States, and Germany, and is committed to the research and development and production of high-end coatings. The use of the CS-580 of Caipu Technology this time will surely lead to a combination of strong companies to improve the quality of the company's products and create better benefits.