In the article "Analysis of Factors Affecting Cupping Test Data", the author Zheng Yanfu et al. used different batches and different thicknesses of oil drum boards, and used semi-automatic digital display cupping testing machines under different blank-holding forces and different cupping speeds. The cupping test was carried out separately, and the main factors affecting the accuracy of the cupping value were found: sample thickness, blank holder force, and cupping speed.

Experimental analysis data

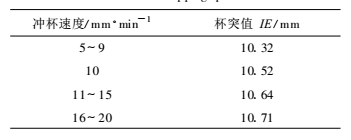

1. Cupping value test results at different cup speeds

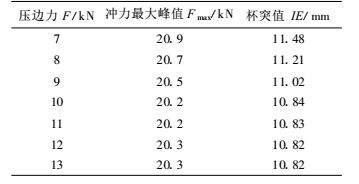

2. The measurement results of the maximum peak value of impulse force and cupping value under different blank holder forces

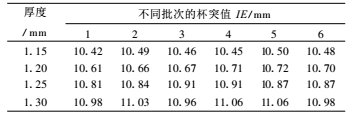

3. Experimental results of different batches, different thickness samples and cupping values

It can be seen from the above table that for the same metal material, under the same rolling state and test conditions, the cupping value increases as the thickness of the sample increases.

The blank holder force is inversely proportional to the cupping value; a good cupping speed is controlled at 10mm/min, which can ensure the accuracy of the test.