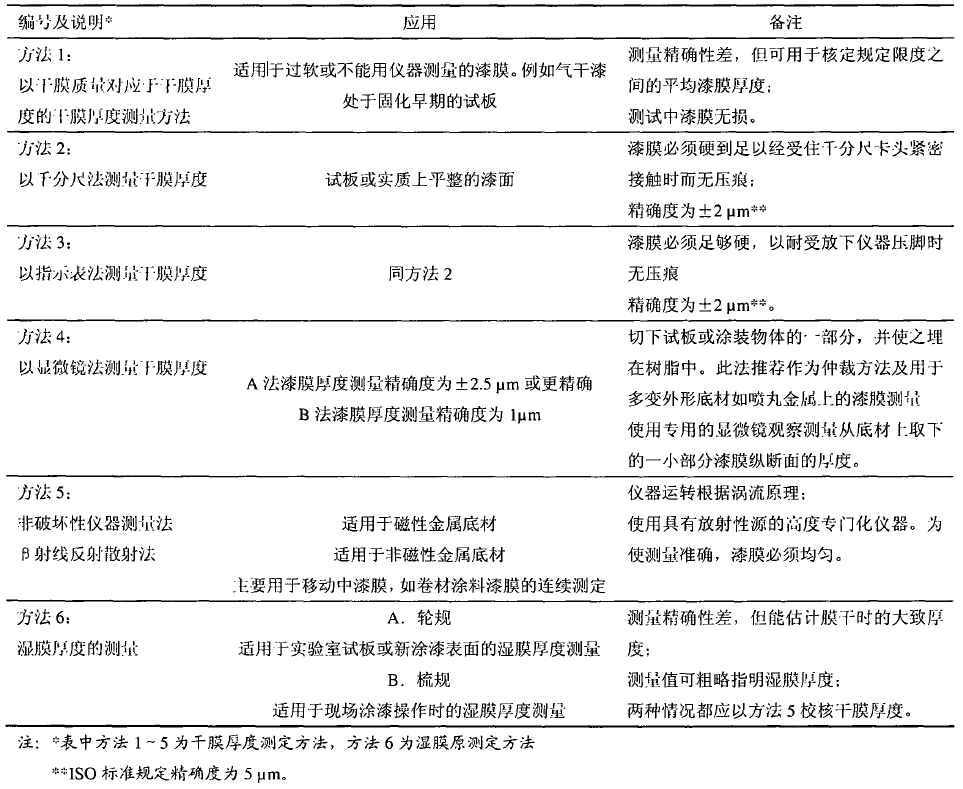

The current national standard equivalently adopts the international standard ISO2808-1974 to formulate "GBT/13452.2-92 Determination of Paint Film Thickness of Paints and Varnishes", which stipulates the measurement method of paint film thickness of paints and related materials, see Table 1.

Table 1 Measurement methods for paint film thickness of paints and related materials

Determination of dry film thickness

What is often encountered in practical work is the measurement of dry film thickness. At present, there are many methods and instruments, but each method has certain limitations, and only a few of them can be applied to all types of samples and environments. According to the working principle, it can basically be divided into two categories: magnetic method and mechanical method.

(1) The magnetic method can be measured by magnetic and non-magnetic Thickness Gauges according to the different substrates to be tested. The magnetic Thickness Gauge mainly uses the principle of electromagnetic field reluctance to measure the thickness of the coating on the steel substrate; the non-magnetic Thickness Gauge uses the principle of eddy current thickness measurement to measure the thickness of the coating on the non-magnetic substrate such as aluminum plate and copper plate. . It should be noted that some paint varieties contain iron red, aluminum powder, etc., which will have a certain impact on the test results.

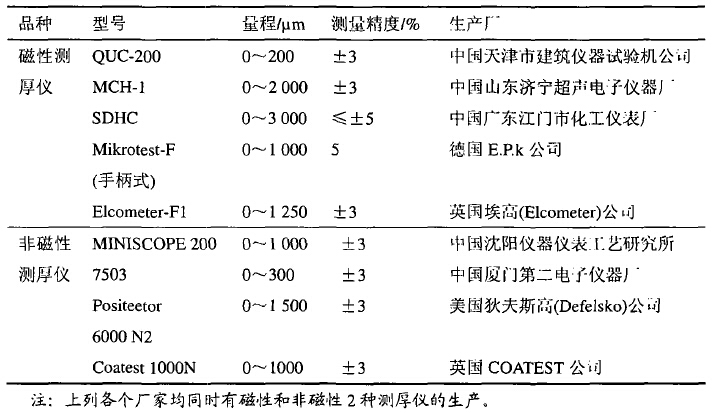

Magnetic method has become the main method of dry film thickness determination. There are magnetic and non-magnetic Thickness Gauges produced at home and abroad, and at the same time continuous improvement, a variety of types and grades of Thickness Gauges have been developed. For example, permanent magnets are used instead of electromagnetic fields to measure the thickness of the dry film on the construction site. The structure is simple and convenient. Portable, but the accuracy is slightly poor, change the power supply to dry batteries or rechargeable batteries, so that the structure is compact, easy to carry, and still maintain high accuracy. The current Thickness Gauge is mainly digital display type, which can directly read out the data, and is suitable for measuring the thickness of surfaces with various shapes.

The models and specifications of commonly used magnetic Thickness Gauges and non-magnetic Thickness Gauges can be found in Table 2.

Table 2 Models and specifications of commonly used magnetic and non-magnetic Thickness Gauges

(2) Mechanical method

The method of using a lever micrometer or a dial gauge to measure the thickness of the coating film has been used for a long time. The advantage is that it is not limited by the properties of the substrate and is not affected by the conductive or magnetic pigments in the paint film. The accuracy of the instrument itself is up to 2 μm. However, it can only be tested on a small area of the sample. In order to eliminate the error, multiple measurements are required, and the procedures are cumbersome. It is not as simple as a magnetic Thickness Gauge.

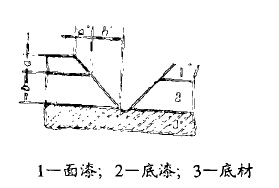

测定漆膜厚度的显微镜法, 已被建议为漆膜厚度测定的仲裁方法。其测试原理如图1 所示。该法是用一定角度的切割刀具将涂层作一V 形缺口直至底材, 然后用带有标尺的显微镜测定a ` 和b’ 的宽度。标尺的分度己通过校准系数换算成相应的微米数, 因此可从显微镜中直接读出漆膜的实际厚度( a、b )。此法的最大优点是除能测定总漆膜厚度外,还能测定多层漆系统的每层漆的漆膜厚度, 同时可以在任何底材上进行, 其不足之处是将使漆膜遭受局部破坏。

图1 显微镜测试法

图2 轮规

湿膜厚度的测定

湿膜的测量需要在漆膜制备后立即进行, 以免由于挥发溶剂的蒸发而使漆膜发生收缩。《GB/T13452.2 -92 》的方法6 中规定使用轮规和梳规测定的方法。在美国ASTMD1212-79 中规定用轮规和用Pfund 湿膜计测定的方法。

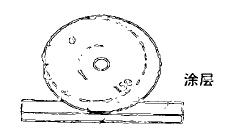

①轮规基本上是由3 个圆盘组成的, 一个整体, 外侧两个圆盘同样大小, 中间圆盘是偏心的,且半径较短, 以使3 个圆盘在某一半径处相切( 即处在同一平面上), 这样该处的间隙为零。在相反的半径方向上, 间隔即为最大。在圆盘外侧有刻度,以指示不同间隙的读数。

测试时( 见图2) 须注意仪器需要垂直于被测表面, 不能左右晃动, 否则将得出不正确的结果; 另外仪器在表面上滚动, 若是由零开始, 则由于湿膜的被挤压而把漆推向前, 得出的厚度读数将大于实际湿膜厚度, 使结果产生一定的误差。

②梳规一种可随身携带的金属或塑料片, 形状为正方形或矩形, 如图3 所示。在其4 边都切有带不同读数的齿, 每一边的两端都处在同一水平面上, 而中间各齿则距水平面有依次递升的不同间隙。使用时将其垂直接触于试验表面, 这样将有一部分齿被漆膜所沾湿。湿膜厚度为在沾湿的最后一齿一与下一个未沾湿齿之间的读数。梳规是一种价格低廉的简便测量仪器, 特别适用于在施工现场使用。

图3 梳规

图4 Pfund 湿膜计

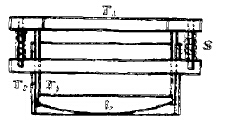

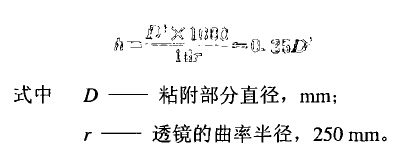

③ Pfu dn wet film meter instrument is composed of a convex mirror L (with a radius of curvature of 25 0 ~ ) and two metal round tubes T l and a few, see Figure 4. When in use, slowly press the tube T l down by hand, so that the lens L installed at the bottom touches the surface of the substrate through the wet film, measure the diameter of the part where the paint adheres to the lens, and calculate it according to the following formula: Wet film thickness, expressed in μm

It should be pointed out that due to the surface tension of the coating film on the mirror surface, the measured wet film thickness is slightly different from the actual wet film thickness. The formula is established under the assumption that the two are completely equal. In order to make the results more reliable, a correction factor needs to be introduced, see American ASTMD1212-79 for details.

From the practical application point of view of the above three kinds of Film Thickness Gauges, the wheel gauge is more satisfactory. It can be used not only in the laboratory, but also in the field for measurement. It is easy to use and accurate in reading.

Although the Pfudn wet Film Thickness Gauge is more accurate, the operation and calculation are more cumbersome. Comb gauges are cheap and easy to carry, but have large errors and can only be used for rough measurement of wet film thickness on the construction site.

For more details, please refer to the full text of "Testing Fanggu for Paint Film Thickness" (Deng Shaoqing, Sun Enyi)