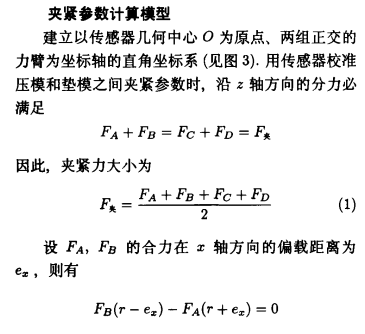

The cupping test machine is mainly used to test the cold stamping plastic deformation performance of metal plates and metal strips with a thickness of ≤4mm. Then even if a very satisfactory standard sample is used, some abnormal scenes will appear in the cupping test. Through a large number of tests, it is found that: (1) The clamping force between the die and the pad die is not uniform, that is, the clamping force exists Azimuth error; (2) The problem of the different axis between the punch and the die, so the author researched the clamping parameter calibration technology of the cupping testing machine. The article "Research on Calibration Technology of Clamping Parameters of Cupping Testing Machine" introduces a solution of a cross-shaped cantilever beam force sensor for calibrating clamping parameters proposed by the author, and establishes a mathematical model for calculating clamping parameters.

In addition, the stress state, manufacture of the force sensor, calibration of the entire calibration device, nonlinear error correction and measurement data processing are discussed, which provides sufficient technical basis for the comprehensive calibration of the clamping parameters of the cupping testing machine.