Lithium-based grease is currently an important type of grease, accounting for more than 70% of global grease products, and is widely used in various industries. The dropping point of lithium-based grease is generally greater than 180°C. It has good water resistance, mechanical stability, rust resistance and oxidation stability. It is a kind of grease with multi-purpose, long life and wide temperature range.

The preparation method of lithium-based grease is relatively simple, the sensitivity of additives is good, and the compatibility with many types of grease is good. Most of the base oils can be used as raw materials for lithium-based grease.

Lithium-based greases with different components exhibit unique properties:

1) Grease made of 12-hydroxy lithium stearate soap has a high dropping point, thick soap fiber, strong shear resistance, and good mechanical stability.

2) Grease prepared with lithium stearate soap has good colloidal stability.

3) The lithium-based grease prepared by mixing 12-hydroxystearic acid and stearic acid has good mechanical stability and colloidal stability.

4) Mix lithium-based grease with calcium-based grease, the mixed grease has good mechanical stability, colloidal stability, water resistance and wear resistance. When the ratio of raccoon soap to calcium soap is 8:2, the mixed grease can obtain a lower coefficient of friction.

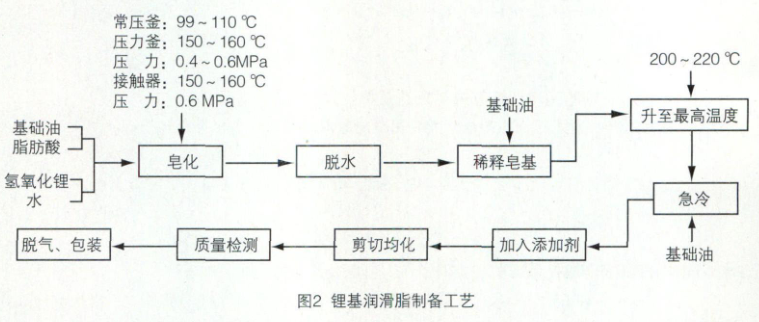

The preparation process of lithium-based grease is as follows: