Roller coating is a construction method that uses a rotating roller coated with paint to coat the surface of the workpiece with paint. Roller coating is suitable for the coating of flat metal plates, plywood, and paper, especially for high-speed coating of metal coils.

The advantage of this method is that it is beneficial to automatic flow production, and it is especially suitable for the coating of large-volume and large-area flat parts. Plywood and metal plates are almost all coated by roller coating. It can be coated on one side or both sides at the same time. The roller coating method is suitable for coatings of various viscosities. The coating film can be thick or thin. The leveling property of .ll paint is better, otherwise the paint film will burr. The running speed of the workpiece is generally 5~25m/min, and that of the pre-coated coil is 40~100m/min.

The roller coating method can be divided into manual group coating and automatic roller coating. The tools for manual roller coating are rollers and roller coating pans. Hand roller application is the fastest method of manual application and is widely used to apply architectural coatings on walls and ceilings. The requirements for paint viscosity during roller coating are similar to brush coating. When applied with a roller, it will also produce a ribbed paint film surface, and the paint will splash, and it is necessary to mask and cover the places that do not need to be coated. Automatic roller coating is suitable for surface coating of boards, coils, plastic films, plywood, paper, etc. It has the characteristics of effective, low consumption, low cost, and good quality of paint film.

The equipment of automatic roller coating is automatic roller coating machine, has single-sided roller coating machine and double-sided roller coating machine. The roller coating equipment is composed of pretreatment, roller coating machine and baking equipment, and the roller coating machine is composed of coating mechanism (feeding roller, coating roller and coating plate), steering support mechanism and driving motor. Roller coaters are available in the following types to suit various applications.

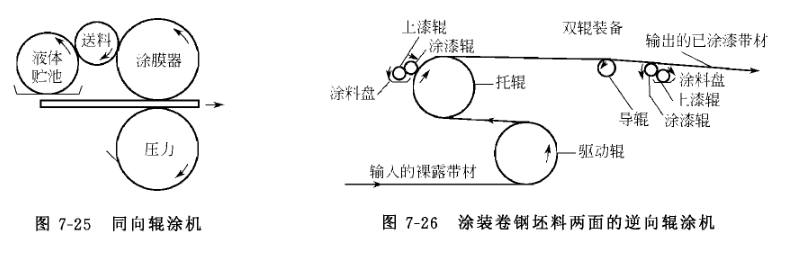

①Same-direction roller coater (see Figure 7-25) is suitable for thin coating of low-viscosity paint, with a dry film thickness of 10-20µm and a line speed of no more than 100m/min. The thickness of the coating film is adjusted by adjusting the gap between the rollers. ②The reverse roller coating machine (see Figure 7-26) can apply high-viscosity coatings to obtain thick coatings. The wet film thickness is 5o~1ooµm, and the viscosity of the coating can be adjusted On 12os and above. The thickness of the coating film is adjusted by the gap between the take-up roller and the applicator roller. High-viscosity coatings are likely to cause insufficient feeding, and the top feeding method should be adopted, relying on the gravity of the coating itself to ensure sufficient material supply, and the coating effect is adjusted by the speed ratio between the coating roller and the backup roller. When coating in the same direction, the speed ratio of the coating roller and the backup roller should be less than 1 to improve the surface quality of the coating film. When coating in the reverse direction, the speed ratio should be slightly greater than 1 so that the coating of the coating roller can be evenly transferred to the coil.