Introduction of homogenization process

A typical glue leveling process includes several steps of glue dropping, high-speed rotation and drying (solvent volatilization).  In the glue dropping step, the photoresist is dripped onto the surface of the substrate, and the photoresist is spread on the substrate to form a thin layer by high-speed rotation, and the excess solvent in the glue layer is removed in the drying step. Two commonly used dispensing methods are static dispensing and dynamic dispensing.

In the glue dropping step, the photoresist is dripped onto the surface of the substrate, and the photoresist is spread on the substrate to form a thin layer by high-speed rotation, and the excess solvent in the glue layer is removed in the drying step. Two commonly used dispensing methods are static dispensing and dynamic dispensing.

Static dispensing is to simply pour the photoresist onto the center of the stationary substrate surface, and the dispensing volume varies from 1-10ml. The amount of glue dropped should be determined according to the viscosity of the photoresist and the size of the substrate. If the viscosity is relatively high or the substrate is relatively large, it is often necessary to drop more glue to ensure that the entire substrate is coated with glue during the high-speed rotation stage.

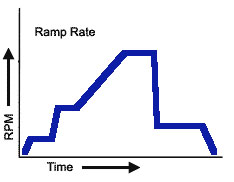

The dynamic dispensing method is to dispensing glue while the substrate is rotating at a low speed (usually around 500 rpm). The function of "dynamic" is to make the photoresist spread easily on the substrate and reduce the waste of photoresist. Dynamic dispensing does not require much photoresist to wet (spread to cover) the entire substrate surface. Especially when the wettability of the photoresist or the substrate itself is not good, dynamic dispensing is especially suitable, without pinholes. After dispensing glue, the next step is high-speed rotation. To thin the photoresist layer to the final required film thickness, the rotation speed at this stage is generally 1500-6000 rpm, and the selection of the rotation speed also depends on the performance of the photoresist (including viscosity, solvent volatilization speed, solid content and surface tension, etc.) and the size of the substrate. Fast spin times can range from 10 seconds to several minutes. The rotation speed of the glue and the time of the glue can often determine the thickness of the final film.

Generally speaking, the speed of homogenization is fast, the time is long, and the film thickness is thin. There are many variable factors affecting the homogenization process, and these factors tend to cancel each other out and tend to balance during the homogenization. Therefore, it is better to give enough time to the homogenization process to allow many influencing factors to reach a balance. An important factor in the dispensing process is repeatability. Subtle changes in process parameters will bring about huge differences in film properties, and some variable factors are analyzed below:

spinning speed:

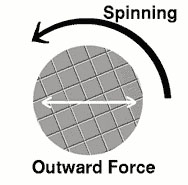

The speed of homogenization is an important factor in the homogenization process. The rotational speed of the substrate ( rpm ) affects not only the centrifugal force acting on the photoresist,  but also the characteristic turbulence of the air immediately adjacent to the substrate surface and the relative velocity of the substrate and air. The final film thickness of photoresist is usually determined by the coating speed. Especially in the stage of high-speed rotation, such a small change of rotation speed ± 50rpm can cause a 10% deviation in the final film thickness.

but also the characteristic turbulence of the air immediately adjacent to the substrate surface and the relative velocity of the substrate and air. The final film thickness of photoresist is usually determined by the coating speed. Especially in the stage of high-speed rotation, such a small change of rotation speed ± 50rpm can cause a 10% deviation in the final film thickness.

Film thickness is largely a result of the balance between the shear force acting on the liquid photoresist, directed towards the edge of the substrate, and the rate of drying (solvent evaporation), which affects the viscosity of the photoresist. As the solvent in the photoresist continues to volatilize, the viscosity increases until the centrifugal force of the substrate rotation acting on the photoresist can no longer move the photoresist on the substrate surface. Up to this point, the thickness of the adhesive film will not become thinner with the extension of the uniform glue time. All ANALYSIS (Anses (CHINA) Co., Ltd.) glue homogenizer specifications require that within the range, no matter which speed is selected, the speed deviation of the glue homogenizer should not be greater than ±1rpm. Usually the actual deviation is ±0.2rpm. Moreover, the resolution of all control programs and speed displays is 1 rpm.

acceleration

The acceleration of the substrate during the coating process will also affect the performance of the adhesive film. Because in the first stage of substrate rotation, the photoresist starts to dry (solvent evaporates). So precise control of acceleration is very important. In some dispensing processes, 50% of the solvent in the photoresist evaporates within seconds of the dispensing process. The acceleration also plays an important role in the quality of the adhesive film when distributing the adhesive on the substrate that has been photoetched with patterns. In many cases, fine patterns have been left over from previous processes on the substrate. Therefore, it is important to spread the glue evenly across the patterns on such substrates. The homogenization process always produces a centrifugal force on the photoresist, and it is precisely the acceleration that produces a twisting force on the photoresist. This torque causes the photoresist to spread around the existing pattern, so that it is possible in another way. Cover the patterned portion of the substrate with photoresist. The acceleration of ANALYSIS (Anses (CHINA) Co., Ltd.) homogenizer can be set, with an accuracy of 1rpm/second. In operation, the motor accelerates (or decelerates) in linear ramps to final dispense speed.

Exhaust

The drying speed of photoresist in all dispensing processes depends not only on the properties of the photoresist itself (such as the volatility of the solvent system used), but also on the air conditions around the substrate during the dispensing process. A damp cloth dries quickly on a dry, windy day, but dries slowly in humid climates. Photoresist dries at a similar rate and is also affected by ambient conditions. Everyone knows that factors such as air temperature and humidity play an important role in determining the properties of the film. When dispensing, it is also very important to reduce the flow of air above the substrate and the turbulence caused by the flow of air, or at least keep it stable. All ANALYSIS (Ansaisi (CHINA) Co., Ltd.) glue homogenizers adopt the "closed bowl" design. Although the closed bowl is not actually a completely airtight environment, the exhaust hood allows a small air flow to pass through during the coating process, and cooperates with the bottom exhaust port located under the rotary head (suction cup) of the coating table. The exhaust hood becomes a channel of the exhaust system to reduce

Undesirable random turbulence purposes. This system has two obvious advantages: the drying speed of the resist is slow during the coating, and the sensitivity to the ambient humidity is small. The advantage of slower drying (solvent volatilization) is that the thickness of the adhesive film is uniform. During uniform coating, when the photoresist is thrown to the edge of the substrate, the photoresist is also dried due to the volatilization of the solvent. This will cause the thickness of the photoresist film to be uneven in the radial direction. Because the viscosity of the photoresist varies with the distance from the center of the substrate to the edge. By reducing the rate of solvent evaporation it is possible to keep the viscosity of the photoresist relatively constant across the substrate surface.  The drying rate and the associated final film thickness are also affected by the ambient humidity, and changes of only a few percentage points in relative humidity can cause large changes in film thickness. In a "closed bowl", the solvent in the photoresist volatilizes, and its vapor is left in the bowl, which masks the effects of small humidity changes. When the homogenization process is over, open the exhaust hood to take out the substrate, maintain sufficient exhaust, and exhaust the solvent vapor.

The drying rate and the associated final film thickness are also affected by the ambient humidity, and changes of only a few percentage points in relative humidity can cause large changes in film thickness. In a "closed bowl", the solvent in the photoresist volatilizes, and its vapor is left in the bowl, which masks the effects of small humidity changes. When the homogenization process is over, open the exhaust hood to take out the substrate, maintain sufficient exhaust, and exhaust the solvent vapor.

Another advantage of the "closed bowl" design is that the film quality is less sensitive to changes in air flow around the substrate. For example, in a typical clean room there is always a steady vertical laminar flow of air from top to bottom at about 100 feet per minute (equivalent to 30 m/min). There are several factors that affect the local quality of this air stream. Common problems are disturbance (turbulence) and eddy current (eddy current). Small changes in the environment can cause drastic changes in the downdraft. Covering the "bowl" with a smooth-surfaced cover eliminates environmental changes and turbulence in airflow due to the presence of operators and other equipment.

Uniform glue process data chart

The following four graphs represent general trends in the effect of various process parameters on homogenization results. For most photoresists, final film thickness is inversely proportional to dispense speed and dispense time. If the exhaust air volume is too large, the film will dry unevenly due to air turbulence (turbulence), but the film thickness is still proportional to the exhaust air volume to a certain extent.

Common problems of glue homogenization process:

| Problem 1: Bubbles appear on the surface Possible reasons: There are bubbles in the glue when dispensing glue There is a problem with the incision of the tip of the nozzle or there are thorns |

|

| Problem 2: There are radial stripes around the possible reasons: the glue injection speed is too high, the exhaust speed of the equipment is too high, the static time before glue coating is too long, the speed or acceleration of the Spin Coater is set too high, there are small particles left on the surface of the film, and there are particles in the glue |

|

| Question 3: A swirl pattern appears in the center. Possible reasons: The exhaust velocity of the equipment is too high. The glue liquid deviates from the center of the substrate when the glue is sprayed. |

|

| Question 4: There is a halo in the center Possible reasons: Inappropriate tray, the nozzle deviates from the center of the substrate |

|

| Question 5: The glue is not fully coated on the substrate. Possible reason: Insufficient glue supply and inappropriate glue uniform acceleration |

|

| Question 6: Possible causes of pinhole phenomenon : dust in the air, particles in the photoresist or bubbles on the substrate |

|