Foreword and purpose

In the surface treatment process of various products, the adhesion between the spray paint and the substrate is poor, and problems such as paint peeling, blistering, and cross-hatch test failure often occur. The surface of the substrate is not clean, and pollutants such as oil stains, oil dust, and fingerprints are the key reasons for poor adhesion. And 70% of the defects in surface treatment are caused by the cleaning process.

The Cleanospector oil cleanliness meter developed by SITA in Germany is currently the only instrument in the world that can quantify the cleanliness of metal, ceramic, and glass surfaces. The SITA Cleanospector oil cleanliness instrument quantitatively detects organic pollutants such as oil, grease, wax, adhesives, fingerprints, and residual cleaning agents on metals, ceramics, and glass through fluorescence excitation. The research results and long-term experience show that these Excessive residues of organic pollutants are one of the main reasons that affect the effect of subsequent processes such as welding and spraying. The cleanliness of the workpiece after cleaning is monitored by the SITA Cleanospector oil cleanliness instrument, and the cleanliness standard can be established to avoid excessive residues of adhesives. The problem of poor spray adhesion or even failure to spray.

SITA CleanoSpector has two options for presentation of measurement results. The first Cleanliness mode, measuring the cleanliness value displayed by the instrument as a percentage. A cleanliness value of 100% indicates an absolutely clean and non-fluorescent surface. In the second Fluolevel mode, the measuring instrument uses the RFU value (Relative Fluorescence Units) to indicate the level of cleanliness. RFU is the relative fluorescence intensity value. The larger the RFU value, the higher the residual pollutant content on the surface of the part. In addition, with SITA-Fluoscan software, manual scanning measurement is performed in a dark environment with a scanning time of 30 seconds, and the cleanliness change curve of the entire sample can be obtained.

sample

Sample background: After processing the blanks of automobile nameplates of a company in Shenzhen, the blanks are filmed to prevent scratches and secondary pollution of the blanks. At present, there are two ways of pasting the film: the first is electrostatic adsorption film, and the second is acrylic adhesive (acrylic acid) adhesive film. After the adhesive film is torn off, there will be adhesive residue on the blank board. The engineer believes that this is the main reason for the poor spraying effect in the subsequent process, which may cause the sprayed coating to fail to adhere or the risk of the coating to fall off.

Testing purposes:

Verify that the data from the SITA cleanliness instrument can clearly distinguish the surface cleanliness of various samples.

For example: whether it is possible to distinguish the cleanliness of the rough board with electrostatic film and the rough board with adhesive film;

Sample category:

Processing and description | test numbers | Remark | |

A | Paste 520 adhesive film | 3 | Use percentage mode to measure, and take one of them for sweep measurement |

B | Paste electrostatic film | 3 | Use percentage mode to measure, and take one of them for sweep measurement |

Test Mode: Cleanliness Measurement Software: 1.SITA-Fluoscan 2. Measurement Method: Linear Scan

The sample test adopts a linear scan, and the diameter of the measuring point is 1 mm. Visually compare with graphs. All measured values are detailed in the appendix.

Note: SITA-Fluoscan is a software specially designed for scanning measurement, and the longest single measurement time is 30 seconds. Results are presented as graphs. At the same time, users can read, manage and export all data records.

Scan mode application:

Continuously measure the cleanliness of strip-shaped flat samples using one or more sensors

surface scan mode

Check the cleanliness of flat samples using an XY positioning drive

free scan mode

Measure the cleanliness of the sample surface using a 3D positioning system

The scanning mode of this test is: single straight line scanning.

test site

3 Analysis of test results:

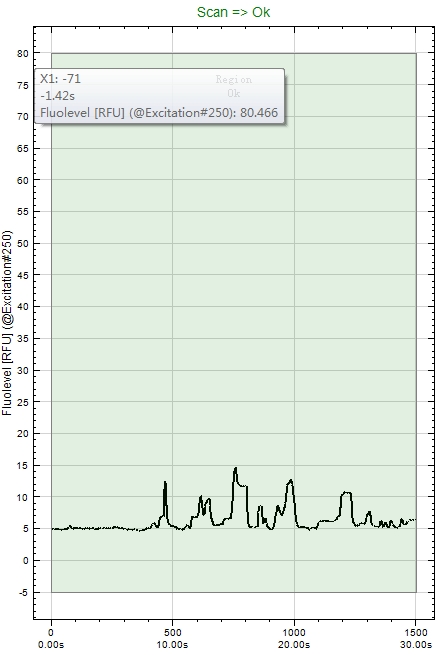

A has an adhesive sample, and the scanned image is shown in the figure

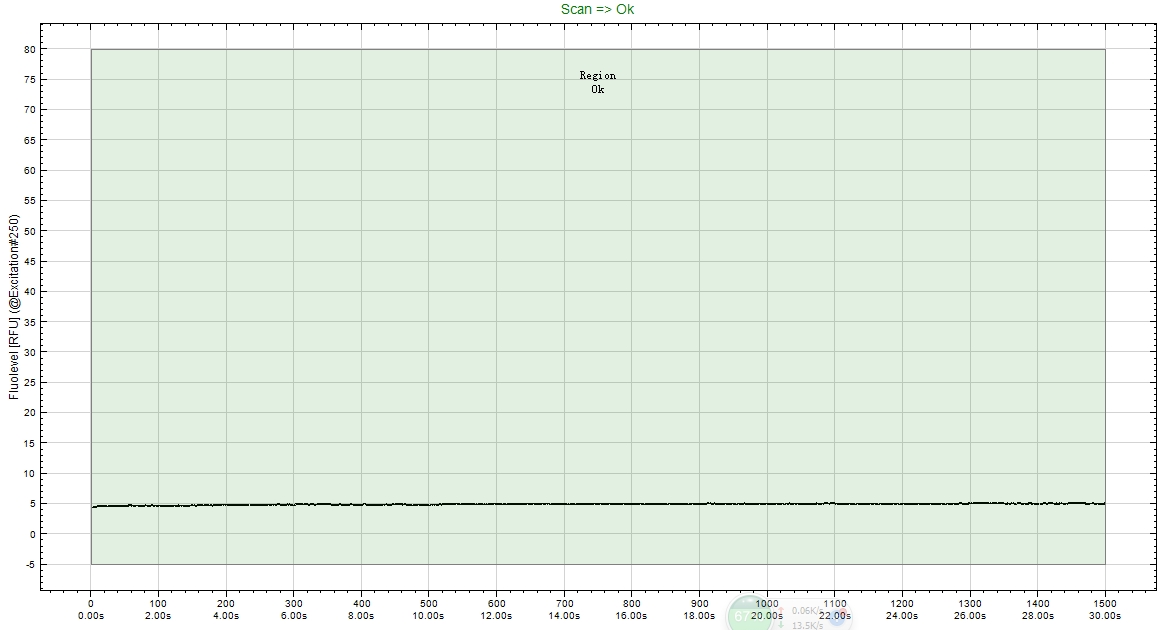

B electrostatically adsorbed samples

analyze:

By comparing the cleanliness curves of samples A and B, it can be found that:

The place where the A sample curve is stable is the clean part of the substrate, and the indication value is about 5RFU; the indication value fluctuates in the middle and rear, and the maximum value reaches 15RFU, indicating that there is adhesive residue in this area.

The curve of sample B has been stable at about 5RFU, with almost no fluctuations, indicating that the cleanliness of the surface of sample B is very uniform and relatively clean.

in conclusion

1. The SITA Cleanospector surface cleanliness meter can detect the acrylic adhesive on the blank plate of the nameplate very well.

2. The indications scanned by the SITA Cleanospector surface cleanliness instrument can faithfully reflect the cleanliness of the scanned area.

3. The curves of samples A and B are in line with expectations. The result of A shows that there is indeed adhesive residue on the adhesive board, and it is in the middle part. Sample B, which is electrostatically adsorbed, should be clean, and the results also show that its cleanliness is very good and there is no secondary pollution.

4. The hand-held SITA CleanoSpector is suitable for simple and fast cleanliness monitoring in factory workshops or laboratories to evaluate the cleanliness quality of nameplate blanks before spraying in the next process.