Q1: Is the PosiTest AT pull-off adhesion Tester strong?

Certainly sturdy. Both manual and automatic PosiTest AT pull-off adhesion Testers are consistent with heavy-duty hydraulic pumps and high-quality industrial pressure sensors in environmentally-sealed metal housings. Can be used indoors, outdoors and in all weather conditions.

Q2: How are Defelsko's manual and automatic PosiTest pull-off adhesion Testers calibrated?

Manual and automated PosiTest pull-off adhesion gauges are calibrated under known conditions using NIST traceable equipment. A calibration certificate for actual measurements is included with every pull-off adhesion Tester.

Q3: How long does it take for Resinlab EP11HT Gray to cure?

It takes 24-48 hours to fully cure at room temperature. Heating accelerates cure time.

Q4: Can curved tops be used on convex surfaces?

Defelsko does not supply or support curved tops for adhesion testing.

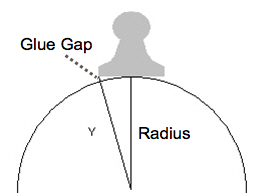

In addition to affecting the surface area used to calculate pull-off strength and the direction of force lines (creating unwanted shear forces), most adhesion testing standards specifically call for the use of flat caps. Feedback from customers is that the innermost or outer pipe application with a diameter greater than 200mm does not require the use of curved tops to obtain satisfactory test results. In this case, the maximum glue gap between the top surface and the coating is 0.5mm.

For the smallest tube diameter, it may be possible to use a 10mm or 14mm cap, depending on the expected coating pull strength. The smaller surface area of the caps will cause them to lie flat on the surface. The height of the drive pullout becomes the limiting factor on the inside diameter. The outer diameter can be reduced to 50mm and 100mm respectively.

Q5: Can the pull-off adhesion test be done underwater ?

Yes, but the PosiTest pull-off adhesion Tester can only be used for underwater measurements if the cable and drive are placed underwater. In such cases, the following precautions should be taken:

1. The puller sleeve and driver should be dried effectively immediately after the test.

2. After drying, apply a large amount of anti-rust lubricant.

Note: During the test, the manual PosiTest AT requires more than one tension and compression to complete the test. This is different than what we demonstrated in the how-to video.

PosiTest adhesion Testers can be manufactured with longer pressure hoses for underwater measurements.

Q6: What are the conditions of test failure ?

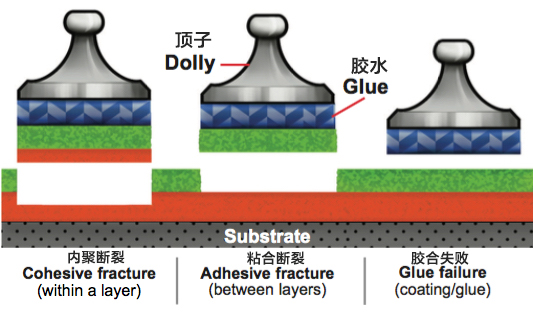

The adhesion test is evaluated by psi or Mpa and visually, as follows:

Cohesive Fracture: Fracture occurs with the same coating (top subsurface and coating surface have the same coating)

Adhesive Fracture: Break occurs between coats on the surface (coating on top subsurface differs from coating on surface)

Glue Failure: Clearly the glue, coating has separated from the crown (no coating on the crown surface)