1. Problems that can be solved by using SITA metal cleanliness measurement:

1. Measure oil stains, grease, cooling lubricants, waxes and other pollutants on the metal surface; quickly find out the causes and locations of poor adhesion in processes such as painting, powder spraying, welding, and gluing by quantifying and displaying the cleanliness data of the workpiece , and make corresponding process improvements based on the basis;

2. Quick sampling inspection can be realized in the workshop, and the cleanliness quality of the workpiece output to the next link can be stabilized by quantifying and displaying the cleanliness data of the workpiece, so as to avoid greater quality risks;

3. Evaluate the cleaning effect according to the cleanliness data and optimize the cleaning process. For example, choose more effective, economical and environmentally friendly cleaning agents for different pollutants; reduce or increase cleaning time according to the evaluation results; optimize cleaning temperature; whether to install nozzles in some parts that are not easy to clean; increase or reduce rinse tanks the quantity, etc.;

4. Quantitatively solve problems, greatly reduce rework and defective rate caused by cleanliness, reduce risks and save costs.

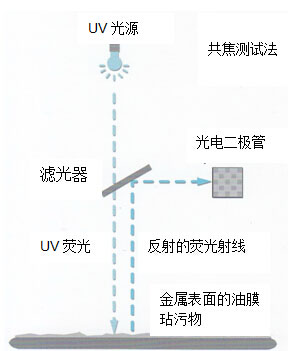

Second, the principle of the instrument

The measurement principle of the SITA cleanliness meter is the confocal method, that is, the excitation light and the light generated by the excitation are on the same parallel radiation track. Therefore, both flexible positioning of the probe and online measurement are easily realized. Based on this test principle, the instrument can detect the cleanliness of parts that do not contain or contain slightly fluorescent materials.

Due to the fluorescent properties of the contamination, the SITA Surface Cleanliness Tester can detect the contamination by illuminating it with an LED lamp containing ultraviolet light waves. A photodiode in the instrument probe measures the intensity of the UV fluorescence. The stronger the UV fluorescence, the greater the degree of pollution, and vice versa, the cleaner.

Fluorescence produced after ultraviolet irradiation is a special form of luminescence. When electrons in fluorescence analysis absorb photons, their energy increases, but this state is not stable. It will immediately return to the initial state and release the absorbed energy again to emit fluorescence. Since part of the energy is converted into heat and consumed, the energy of the emitted light decreases and the wavelength becomes longer.

3. Test environment requirements

Temperature requirements: Storage temperature: -20~60℃

Working temperature: 10~40℃

Environmental requirements:

When using a full-enclosed spacer for contact measurement, it is carried out in a visible light environment;

When using non-contact measurement, it must be carried out in a dark environment or under a red light.

Good measurement spacing: 4.7mm

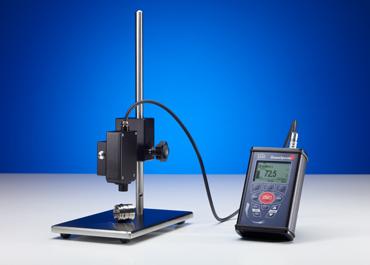

4. Equipment picture

SITA CleanoSpector Surface Cleanliness Meter

5. Actual test cases and reports

![]() SITA Surface Cleanliness Tester Gree Sample Test Report

SITA Surface Cleanliness Tester Gree Sample Test Report