金属零部件上涂层的质量,很大程度上受金属表面污染物的影响,如矿物油和油脂。这些污染物通常在涂层的成型过程及在对金属进行机械加工的过程中产生。对金属材料进行喷涂之前,应先将其污染物清洗干净,因为在金属表面的污染物会影响金属底材与涂层之间的附着力,令其附着力显著降低。

若金属零部件的表面上附有矿物油和油脂等污染物,就会使涂层容易形成一层剥离膜,涂层的质量就会受到影响,后续的补救措施则令最后的成本提高!

当使用有静电电荷的粉末涂料,向零部件上进行喷涂时,由于静电会附在于零件上,随后经过液相(即粉末涂料)出现,从而形成封闭的涂层膜。

为了得到一个高质量的粉末涂料处理表面,除了转化涂层(如磷化)的应用工艺技术,更需要一个干净的除油零部件。而后者是所需的,因为金属零件底材的表面清洁程度,是粉末涂料对金属零部件形成较高粘合强度的先决条件。

脱脂过程通常使用碱性或酸性清洁剂对金属零部件进行浸浴或喷淋清洗。进行脱脂时对清洗槽的参数有特定要求,如洗涤剂的浓度,温度和油的含量等,这些条件均会影响金属零部件的表面清洁度。

当金属零部件接触到少量的腐蚀性物质时,便可脱除金属表面的污垢。在这种情况下,对涂料的粘附性而言,金属底材的脱脂过程变得更加重要!

不同应用之间的差别

According to不同的行业和实际中的应用,会因不同的后续处理步骤,而对不含油脂的金属表面上的阈值进行定义。

例如,According to德国标准DIN Technical Report 28“防护涂料对钢结构的腐蚀防护”中“重大型腐蚀保护”,配套用于涂层材料的涂料液表面碳含量限制在50 mgC/m2。相反地,在汽车工业中,则要求钢表面涂布前表面碳含量少于15 mgC/m2,作为一个油脂/非油脂比较值。

According to the Institute of Corrosion and Protection (ICS) of Dresden GmbH Dresden Co., Ltd., a large number of damage cases in recent years are caused by poor surface cleanliness of the substrate. In most cases these are mechanical parts made of structural steel or galvanized steel, so half a square meter of hydrocarbons up to 1.000 mg/m2 can be completely removed from the steel substrate with a drawdown blade under the coating. Typical coating damage is shown in Figures 1 and 2. These examples can fully reflect the serious consequences of insufficient degreasing.

Figure 1 and Figure 2 have poor adhesion between the coating and the substrate

After the coating is damaged, it needs to generate an excessive repair cost. These damaged parts must be reworked for re-coating or spraying. After the parts are depainted, the metal parts need to be cleaned more effectively to make the new coating have better adhesion!

ICS analyzes the carbon content on the surface. Due to the size limitation of the analytical instrument on the sample (the maximum measurement range is 30 mm in diameter and 140 mm in length), large metal material samples need to be additionally cut. The hydrocarbons on the surface of the cut sample burn at a temperature ranging from 450 to 850 degrees Celsius, releasing carbon dioxide. The infrared sensor will measure the concentration of carbon dioxide in the air flow, and then calculate the carbon content on the metal surface based on the concentration.

Figure 3 SITA Surface Cleanliness Tester

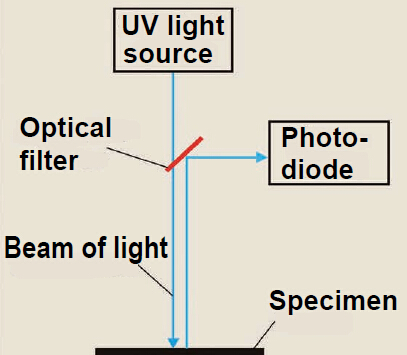

For further analysis, in addition to the above detection methods, the newly developed SITA CleanoSpector surface cleanliness instrument (see Figure 3) can also be used for non-destructive detection of impurities on the surface of parts. The cleanliness instrument developed by SITA Measurement Technology Co., Ltd. can detect hydrocarbon-containing impurities through fluorescence excitation technology with ultraviolet light. The strong fluorescence reflected by organic matter enables us to detect the grease attached to the metal surface, making it possible to carry out anti-corrosion to protect the product! The intensity of the fluorescence depends on the content of dirt and impurities on the measurement point, and its intensity is determined by the sensor head. photodiode for measurement.

Figure 4 Measuring principle

This cleanliness meter adopts the principle of confocal measurement, as shown in Figure 4. The excitation light emitted by the fluorescence always radiates along the same parallel path, so the positioning of the sensor head is no problem and rough surfaces do not affect the measurement results. In addition, the integrated target pointer measuring point locator can help the user to locate a good measuring height. The design of the instrument and the matching portable carrying case make the instrument flexible to adapt to the use environment, and can be used in the production workshop and laboratory. The SITA CleanoSpector cleanliness meter has been proved in many application examples that it is portable, lightweight and easy to operate!

Calibration of the cleanliness meter is automatically set with clean, non-contaminated calibration pieces whose calibration values are stored in the instrument. The number of measurements and calibrations can be adjusted.

Cleanliness percentage

The measurement results are displayed by the cleanliness percentage value. A cleanliness value of 100% means that there is no fluorescent impurity on the surface of the sample, while heavy pollution is displayed as a cleanliness value of 0%. What kind of cleanliness percentage is qualified? The user can set the qualified cleanliness percentage individually according to the actual sample cleaning process.

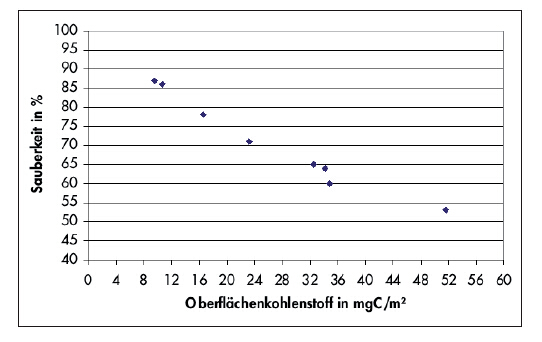

The final cleanliness value results are related to the carbon content of the sample surface, and the measurement results show that the results of the case studies in ICS are based on the detection of contaminated test panels.

Contamination of the test panel can be simulated by dissolving the corrosion protection oil in ethyl acetate. Use this dissolved solution to wet the test panel to be tested. After the solvent on the panel evaporates, the grease will remain on its surface. The surface carbon content of the test plate and the above-mentioned surface carbon content were all measured by fluorescence with the SITA CleanoSpector surface cleanliness instrument. The result is the average of the results obtained at several measurement points on the sample surface.

Fig.5 Relationship between sample cleanliness and surface carbon content

Figure 5 is the surface carbon content function obtained by the SITA CleanoSpector surface cleanliness instrument on the sample plate. The curve in Figure 5 confirms the good correlation between the results of the two methods and shows that the SITA CleanoSpector It can detect the grease attached to the metal surface, at least the surface carbon content up to 9 mg/m3 can be detected. The advantage of the SITA CleanoSpector surface cleanliness instrument is its applicability to various parts without causing damage to the parts. Using this surface cleanliness instrument, for example, some complex coating defects applied to production workshops in Asia can be detected, and then, the defective coating can be repaired immediately.

SITA CleanoSpector cleanliness meter is suitable for checking the surface cleanliness of metal parts before coating and monitoring the cleaning process of parts to ensure the cleaning quality of metal parts and avoid coating defects caused by insufficient cleaning and degreasing.