The cleanliness of the surface of metal parts of medical products needs to reach a very high level in order to meet the safety requirements in the field of human medical applications. Medical products such as implants, sleeves, etc. are in contact with the human body, and testing their cleanliness can greatly reduce medical risks. SITA surface cleanliness meter uses the principle of quantitative fluorescence to conduct non-contact test on the cleanliness of some parts, thus ensuring stable cleaning quality.

Cooling lubricants, corrosion protection materials and drawing oils are all used in the mechanical production of medical products. The chips and particles left by these materials on the surface of the produced parts are the main source of pollution. This contamination on the surface of the part needs to be cleaned before the product is delivered and the next step of production begins. Because subsequent production steps require a high degree of cleanliness of the parts.

Users of SITA surface cleanliness instruments can perform simple and quick cleanliness monitoring of parts to evaluate the quality of the cleaning process. In this way, the effects of parameter deviations and equipment failures are eliminated immediately and process reliability is significantly increased.

SITA tensiometers detect residual contaminants such as oil or cooling lubricants by fluorescence from a UV light excitation source. The photodiode in the sensor head of the Cleanliness Meter measures the intensity of the reflected fluorescent radiation at a wavelength defined in the blue light range.

The higher the intensity of the fluorescence, the higher the level of residual contamination on the surface of the part and the lower the cleanliness value displayed by the measuring instrument as a percentage. A cleanliness value of 100% corresponds to an absolutely clean and non-fluorescent surface. In the case of a highly contaminated part surface, the measuring device will display a cleanliness value of 0%.

The SITA Surface Cleanliness Meter can be calibrated with an absolutely clean surface which is defined as 100% clean. Measure the diameter of the point to 1mm, and press the "START" button to start the measurement directly. A target composite pointer supports fine adjustment of measurement distances. The measurement results of the SITA surface cleanliness instrument, select the cleanliness value that shows the lowest value from the measurement points. In addition, the user can take rolling readouts of all individual readout points measured in the inspection section.

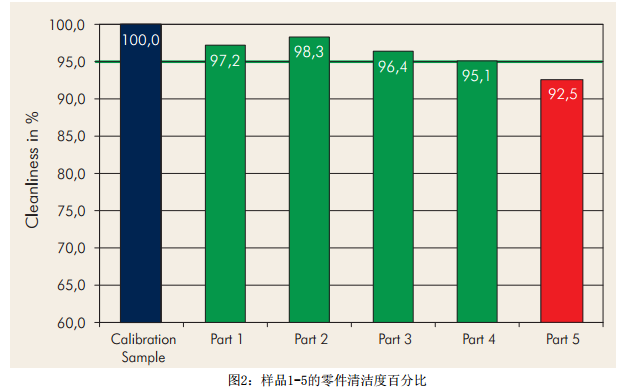

An example is shown in Figure 2, which shows the measured percent cleanliness of a joint prosthesis as it comes off the production line after the final wash. It can be seen from Figure 2 that Part 5 (Part 5) is a part whose cleanliness does not meet the requirements. The limit values for an adequate cleanliness value depend on the need to realize the definition and correspond to the actual application. In the example given above, the limit value is 95%.

On the basis of the received measurement results, the quality inspector is able to identify the cleanliness quality of the resulting product and can therefore take the necessary measures based on the measurement results to avoid dirty cleaning and carry out further cleaning processes.

SITA surface cleanliness instrument provides a good performance test in the field of biomedical engineering. It can be fixed or mobile for actual production and laboratory, because it is simple and reliable in operation, and its small size is easy to carry .