Case: Use the German SITA cleanliness meter to test the surface cleanliness of the nickel sheet to determine whether it will affect the subsequent welding process.

The nickel sheet used in battery packs and PVC circuit boards is not only affected by the welding parameters of the welding machine during the welding process, but also the surface condition of the nickel sheet affects the welding process. Dirt on the surface of the nickel sheet will affect the contact area of the solder joints during oil welding and reduce the firmness of the weld. The inhomogeneity of pollution will also affect the inconsistency of the heating of each solder joint, causing fluctuations in welding quality. On the other hand, oil and other pollutants will increase the contact resistance, and other types of pollutants such as too thick oil film layer will even prevent the current from passing through, and local conduction will occur. Due to the excessive current density, splashing and surface burning will occur. damage. Therefore, a clean and effective nickel surface is a necessary condition to ensure a good joint.

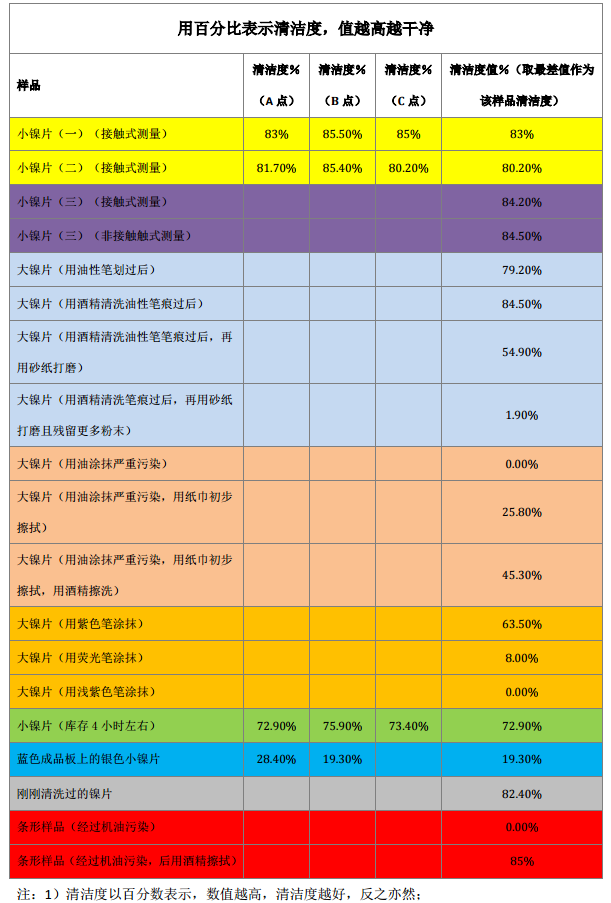

The following is the cleanliness test of a technology company on the nickel sheet. The nickel sheet needs to be welded after cleaning, and the final product is a battery module and components on the circuit board.

Test instrument: German SITA CleanoSpector surface cleanliness meter.

Test process: Take 1 to 3 measurement point readings on each sample, each point has a diameter of 1 mm, and the test time takes about 1 to 2 minutes.

2) Among the measurement points of the sample measurement results, the lowest value of the percentage is used as the final result, that is, the dirtiest point of the sample represents the cleanliness of the entire part;

3) The same color is the same group of comparison tests.

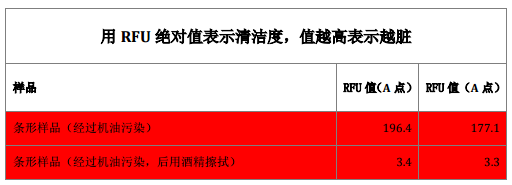

Note: 1) The cleanliness is expressed by the absolute value of RFU, the higher the value, the worse the cleanliness, and vice versa;

2) The same color is the same group of comparison tests.

From the above test data, it is concluded that:

1) For each group of tests, the Sita surface cleanliness meter can effectively and sensitively test samples contaminated by organic pollutants such as oil;

2) After cleaning the polluted samples, the cleanliness is significantly improved; thus, according to the repeated verification of the follow-up process, we can find a suitable range of cleanliness to achieve the purpose of quantitatively controlling the cleaning process, which is to help eliminate and judge product problems after subsequent welding effective means.