In the determination of natural gas density, the draft international standard recommends the use of density balance and vibrating density meter, but the former is mainly used for off-line determination, while the latter is mainly used for on-line or off-line determination. This paper mainly introduces the measuring principle of vibrating density meter.

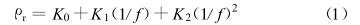

The core component of the vibrating density meter is the sensor—the vibrator, which can maintain the natural frequency vibration, and this frequency value is related to the density of the gas medium in which it is located. When measuring under working conditions, the relationship between vibration frequency and gas density is shown in formula (1).

In the formula: ρ r is the rough density, that is, the density before correction of temperature, pressure and gas composition, kg/m 3 ; f is the vibration frequency, Hz; K 0 , K 1 , K 2 are the vibrator constants of the density meter .

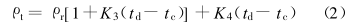

Before measuring the density of natural gas, a reference gas with known density is used for calibration to determine the three constants in formula (1). The formula used at this time is shown in formula (2). In addition to temperature, pressure, gas composition and other influencing factors, if the velocity of sound (VOS) in the measured sample natural gas is different from the reference gas used for calibration, formula (2) should also be used to correct it. In principle, the material properties of the vibrating element are related to the pressure of the medium in which it is located, but in most cases the influence of the pressure is very small and can be ignored. Therefore, formula (2) is a temperature correction formula.

In the formula: ρt is the density after temperature correction, kg/m 3 ; tc is the temperature during calibration, ℃; td is the temperature during measurement, ℃; K 3 , K 4 are the vibrator constants of the density meter.

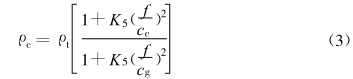

The three constants in formula (1) are related to the composition of the gas that the vibrator is in contact with. Since the relationship between the velocity of sound (VOS) in gas and other gas quality parameters under operating conditions has been determined in detail, the three constants can be determined by using VOS to calibrate the instrument. If the VOS in the calibration reference gas is different from the measured natural gas, the composition-corrected density (ρ c ) and ρ t in formula (2) have a relationship as shown in formula (3).

In the formula: cc is the sound velocity in the calibration reference gas under the operating conditions of the measurement, m/s; cg is the sound velocity in the natural gas to be measured, m/s; K 5 is a constant.

cg in formula (3) is related to the composition of the measured natural gas. It can be measured directly (such as through the signal of an ultrasonic flowmeter), or can be calculated from ρ c , td and temperament parameters. Generally, when the change of cg reaches 10 m/s, the correction item in formula (1) changes about 0.05%. If the required measurement accuracy is not very high, and the difference between cg and cc is not large, ρt can also be used directly without correction of gas composition.