Case: Using the German SITA cleanliness instrument to test the surface cleanliness of aluminum metal parts, to predict possible problems in the welding process, and to reduce defective rates and rework problems.

Hardware products and metal substrates will be polluted by coolant, grease, polishing liquid, finger prints, etc. during processing, which will affect the quality of subsequent processes, such as paint film peeling off, poor welding, coating surface defects, and electrical performance decline, etc. question.

The following is the cleanliness test of an aluminum product company on the aluminum parts delivered to the customer. The aluminum products need to be welded after cleaning, and the final product is a solar module.

During the stamping process, aluminum parts will be stained with stains such as grease, finger prints, etc. During the cleaning process, cleaning agents may remain on the metal surface due to unclean rinsing, so in the subsequent welding process, welding defects will occur. Fixed problems and rework, increasing the cost per unit of business!

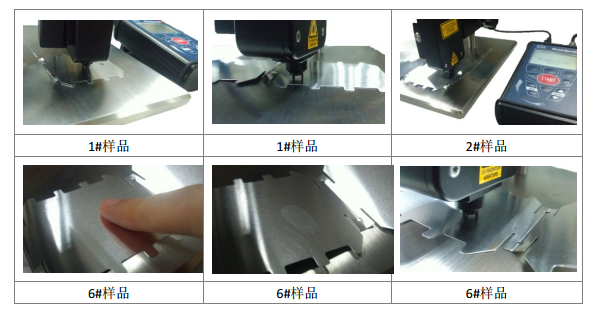

Test instrument: German SITA CleanoSpector surface cleanliness instrument;

Test process: Take readings of 10 measurement points on each sample, each point has a diameter of 1 mm, and the test time takes about 1‐‐2 minutes.

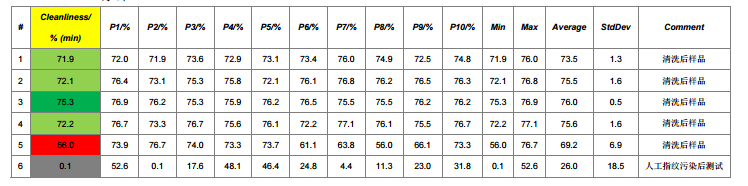

Note: 1) The cleanliness is expressed as a percentage, the higher the value, the better the cleanliness, and vice versa;

2) The measurement result of the sample takes the lowest value of the percentage among the 10 measurement points as the final result, that is, the dirtiest point of the sample represents the cleanliness of the entire part;

3) In addition, the 6# sample is the test result after printing fingerprints on the basis of the original 3# sample, for comparison.

From the above test data, it is concluded that

1) The cleanliness standard deviation std/dev of 1# sample to 4# sample is all less than 2, it can be confirmed that the surface cleanliness of these samples is uniform!

2) The relative cleanliness of the 3# sample is better, while that of the 5# sample is relatively poor.

3) Compared with the 3# sample contaminated by artificial fingerprints, the cleanliness of the 6# sample is 0.1%, and the cleanliness value has dropped significantly, indicating that the instrument can measure the difference between samples with different cleanliness levels, helping enterprises to strictly control the cleanliness and quality of metal parts , to predict the problems that may occur during the welding process, reduce the defect rate and rework problems, and meet the customer's requirements for the cleanliness of the workpiece surface.

The instrument can also be used for optimization of cleaning processes, e.g.

1. When choosing different cleaning agents, identify which cleaning agent has better cleaning effect.

2. When the cleaning time is reduced from 15 minutes to 10 minutes, will the cleaning quality be affected? Quantitative control is better for cleaning time

3. Which part of the metal parts is the most difficult to clean, and whether it is necessary to install a nozzle.

The cleanliness of SITA in Germany helps stabilize production quality and reduce production costs.