Purpose

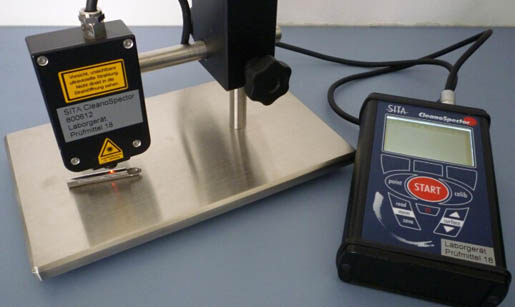

Using a SITA CleanoSpector (SITA surface cleanliness meter), measure the cleanliness of the outside of the metal pipe and the inside of the cut metal pipe (ie cut pipe).

The SITA CleanoSpector (SITA surface cleanliness meter) will have 2 different reading modes. The first readout mode "cleanliness" is a percentage, which shows the percentage value of the cleanliness of the sample surface relative to the cleanliness value of the satisfactory clean calibration piece. The higher the percentage value, the cleaner it is. The second reading mode is FluoLevel, which is the relative fluorescence intensity, and its unit is RFU. The higher the RFU value, the stronger the surface is contaminated by fluorescent substances. This test report uses FluoLevel mode to detect the cleanliness of metal pipes.

The samples tested are listed in Table 1 below.

sample | label |

2 pieces cut tube | No. 1,2 |

5 pieces of uncut tubing | No. 3 - 7 |

Table 1 Tested samples

Test Results

To test the cleanliness of the sample tubes, 10 measurement points should be selected on each sample tube, and the surface cleanliness test should be carried out on the inner wall of the cut tube and the outer wall of the uncut metal tube respectively.

To prepare a clean calibration piece, sample 2 has been cleaned in an ultrasonic Water Bath at 60°C with alkaline cleaner SurTec 151 (3%), rinsed with deionized water and dried.

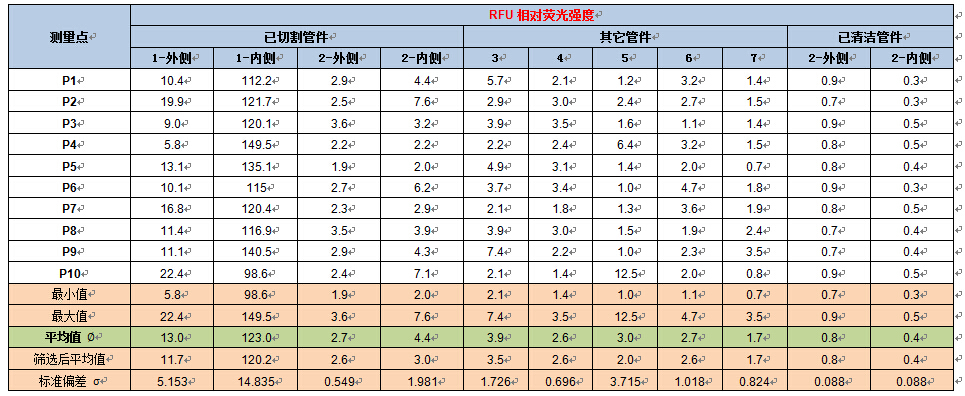

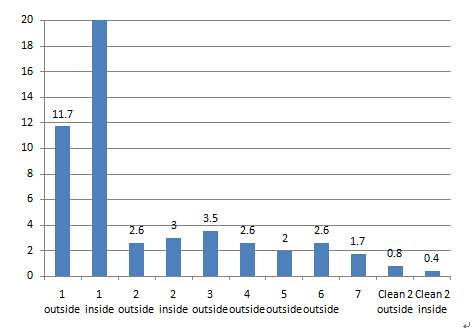

The results of the fluorescence test are shown in FIG. 1 . The measurement results of all measurement points are listed in the figure below

Fig.1 Fluorescence measurement values of each measurement point

Figure 2 The average fluorescence value of all tested samples in RFU

test setup

The test setup is shown in Figure 3-5. Adjust the distance between the lens and the sample through the infrared target point to 4.7mm. In order to achieve a good measurement distance, the infrared point can be adjusted until the minimum diameter appears on the sample surface.

|  |

| Test setup one | Test Setup Two |

| |

| Test Setup Three |

evaluate

Among all the samples, the fluorescence value of sample 1 was significantly higher than that of other sample tubes, especially the fluorescence value of the inner wall; while the fluorescence value of the outer wall of sample 1 was relatively low, but still higher than that of other sample tubes.

The fluorescence values of samples 2-7 are relatively small, while the fluorescence values of sample 2 after cleaning are: 0.8 RFU for the outer wall and 0.4 RFU for the inner wall.