Case: Use the German SITA cleanliness instrument to test the cleanliness of metal nails and piezoelectric ceramics in the motor to quantify the cleanliness data of all workpieces to be welded and stabilize the quality.

The metal parts of the motor are polluted by cutting fluid, wetting oil, release wax, etc. during the process of cutting, stamping, and casting, and need to be cleaned before welding. However, the unstable cleaning quality will cause the welding to be unstable, easy to fall off, and change the electrical properties. Therefore, the German SITA cleanliness Tester is used to test before welding. After the cleanliness is qualified, the welding process is carried out, which greatly reduces the risk of rework.

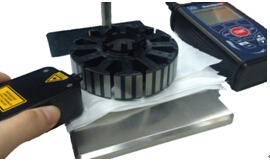

The following is a motor company's cleanliness test on motor nails.

|  |

| Testing process | Testing process |

Test instrument: German SITA CleanoSpector surface cleanliness instrument

Test process: take 10 measurement point readings on each sample, each point has a diameter of 1 mm, and the test time takes about 1-2 minutes.

| # | P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | P9 | P10 |

| 1 not degreased | 18.9 | 13.5 | 26.4 | 125.4 | 15.6 | 28.8 | 45.6 | 30.6 | 30.3 | 64.4 |

| 2 not degreased | 20.5 | 161.4 | 20.7 | 74.6 | 36.6 | 10.8 | 23.0 | 9.3 | 32.3 | 59.3 |

| 3 degreased | 1.4 | 1.6 | 8.4 | 4.9 | 1.8 | 1.3 | 8.7 | 1.2 | 1.3 | 1.5 |

| # | F/RFU (max) | Min | Max | Average | Std Dev | comment |

| 1 not degreased | 125.4 | 13.5 | 125.4 | 40.0 | 33.6 | Undegreased sample, high RFU value, serious contamination |

| 2 not degreased | 161.4 | 9.3 | 161.4 | 44.9 | 45.9 | Undegreased sample, high RFU value, serious contamination |

| 3 degreased | 8.7 | 1.2 | 8.7 | 3.2 | 3.0 | Degreased samples have the lowest RFU and are the cleanest |

Note: 1) The cleanliness is expressed by the absolute value of RFU, the higher the value, the worse the cleanliness, and vice versa;

2) Among the measurement points of the sample measurement results, the highest value of the absolute value of RFU is used as the final result, that is, the dirtiest point of the sample represents the cleanliness of the entire part;

From the above test data, it is concluded that

1) The relative cleanliness of the 3# sample that has been degreased is better, while the relative cleanliness of the 1# and 2# samples that have not been degreased is poor.

2) The SITA cleanliness meter can quickly and accurately measure the cleanliness of the sample, and give quantitative readings, which can directly judge whether the cleanliness of the sample is qualified. To quantify the cleanliness data of the required welding workpieces, and stabilize the quality!

The German SITA cleanliness instrument helps to stabilize the cleaning quality of metal workpieces in the motor and achieve quantitative control!