Foreword and purpose

SITA CleanoSpector is a fast and portable surface cleanliness meter developed by SITA Company in Germany, which can detect the cleanliness of metal surfaces by contact or non-contact. The resulting output is expressed as a percentage or as an RFU value, with 100% indicating an absolutely clean surface. It allows quantitative evaluation of cleaning results to control the cleaning process.

The SITA CleanoSpector measures surface cleanliness by fluorescence from residual dirt on the surface. The ultraviolet light source emits light with a good wavelength to detect pollutants on the metal surface, and the sensor in the instrument detects the fluorescence intensity, which depends on the amount of pollutants at the test point.

SITA CleanoSpector offers a choice of two presentation formats for measurement results. The first is to measure the cleanliness value displayed by the instrument as a percentage. A cleanliness value of 100% indicates an absolutely clean and non-fluorescent surface. The second type, measuring instruments use RFU value (Relative Fluorescence Units) to indicate the level of cleanliness. RFU is the relative fluorescence intensity value, the larger the RFU value, the higher the residual pollutant content on the surface of the part.

During the stamping process of sheet metal parts, there will be pollutants such as oil, dust and fingerprints on the surface. If these pollutants are not treated cleanly, it is easy to cause the problem of unqualified coating adhesion.

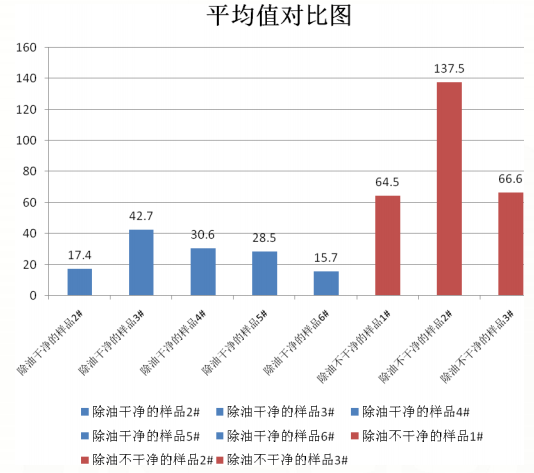

The following are the detection results of Fluolevel mode for clean and dirty samples.

sample

test sample

The sample is tested at 6 points, each point measuring 1 mm in diameter. For comparison, the mean value of the measured values is represented graphically. All measured values are detailed in the appendix.

NOTE: The number of sampling points can be set in the instrument software. The results of the sampling points are displayed in a list form in the instrument. The instrument can automatically calculate the minimum, maximum, average and sample standard deviation. Users can read, manage and export all records.

Test data and conclusion

In this test, the degreasing and clean sample 1 has a test value as high as 622.3rfu due to secondary pollution. The data of sample 1, which was degreased and clean, was excluded because it was not referenced.

Conclusion: 1. The SITA cleanliness meter can quantify and measure samples with different cleanliness, which is consistent with the actual situation.

2. The cleanliness of samples that were not degreased was poorer than those that were degreased, and the cleaning quality fluctuated greatly.