Overview of Conductive Coatings

Conductive coatings are coated on non-conductive substrates, and the coating itself has a certain ability to conduct current and dissipate charges. According to its conductive type, it can be divided into resistance coatings, radio wave shielding coatings, radio wave absorbing coatings, heating coatings, anti-static coatings, electric field mitigation coatings, etc.

The main film-forming substance of conductive coating is polymer, so its conductive principle is mainly to study the conductivity of polymer. Conductive polymers can be divided into two categories: blended additive conductive polymers and intrinsic structural conductive polymers. The blended conductive polymer itself has no conductivity, and its conductivity is achieved by doping conductive particles; the intrinsic structure conductive polymer itself has inherent conductivity, and the polymer molecular structure provides conductive carriers. Due to many difficulties in the synthesis and construction of intrinsic conductive coatings, high cost, and unsatisfactory performance, it has not yet reached the stage of large-scale production, so the current practical conductive coatings are mostly blended conductive coatings. .

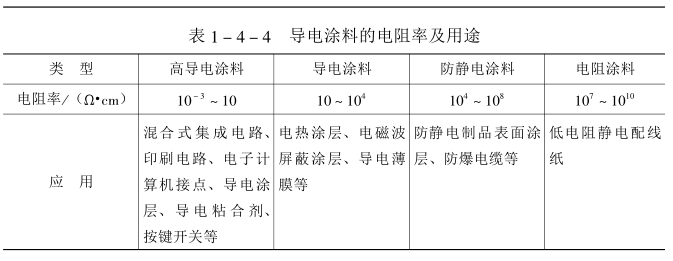

The application purpose of conductive coatings is different, and the required conductivity is also different. The resistivity of conductive coatings for several uses is listed in the table.

Compared with other technical methods for obtaining conductive films such as plastic electroplating and vacuum sputtering, conductive coatings have the advantages of simple equipment, convenient construction, low cost and suitable for complex surface coating.

Application of Conductive Coatings

Conductive coatings are widely used in the modern electronics industry. For example, after the TV picture tube is coated with conductive coatings, the remaining energy can be removed after the power is turned off. In radio electronic devices, electric wave shielding, lead wires of electrode terminals, tuning devices of tape Recorders, TV antennas, outer surfaces of cathode ray tubes, wave conductors, radio reflectors, reflectors of radar intercepting paraboloids and other components need to be coated with conductive coatings .

Using the conductive ability of the conductive coating, electrical energy can be converted into heat energy. Electrothermal coatings can be used to heat residential, industrial and agricultural buildings, and can also be made into food heaters, defrosting, snow and demisting of rear glass windows of automobiles. When used for indoor heating, electric mattresses, and electric foot warmers, due to the large coating area and low resistance, low-voltage currents can be used without risk of contact. Electrothermal paint can also be used as an antifreeze device for oil pipelines and ship hulls in cold areas, and anti-icing on roof roads.

Conductive coatings can be used for anti-static and dissipating static electricity. Glass pipes are often used in industrial systems to transport gases, liquids, and solid powders. The glass used as an insulator will generate static electricity when the friction between the material and the pipe wall during the transportation process causes the inner wall of the pipe to be blocked due to adsorption. If the inner wall of the pipeline is coated with cheap blended paint (such as amorphous graphite as conductive filler), the minimum surface resistance can reach 110Ω·cm , and the static voltage can be reduced to 1/4~1/5 of the original. In addition, the surface of the conveyor belt, the outer surface , the surface of the video tape, the surface of the guide roller of the printing machine, etc., are also coated with conductive paint to eliminate static electricity.

Conductive paint can be used as an insulating shield. After the high-voltage plastic power cable is treated with a semiconductive coating, it has a high dielectric strength and a corona resistance level (that is, suppresses branch discharge), and can play an insulating and shielding role. A good shielding coating should have a specific volume resistance of ρ v =10 5 Ω· cm . The amount of semiconductive coating used for cables is large, so low-cost blended semiconductive materials are generally used.

Electromagnetic shielding and anti-electromagnetic attack are of great significance in the current national defense construction. Among the protective means to prevent leaks, interference, and enemy electromagnetic pulse impact damage, coatings are a convenient material to use. Conductive coatings It is very meaningful work to develop electromagnetic shielding coatings on the basis of .