Light reflective coatings generally use glass beads as light reflectors. The glass beads in the transparent coating or partially exposed on the surface of the paint have a satisfactory reflective effect under sunlight or night light, and are widely used in road marking, Traffic signs, billboards and architectural decoration.

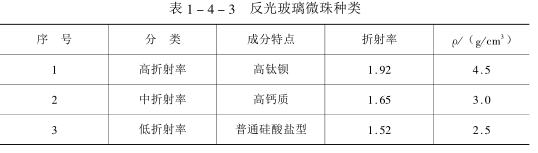

There are many types of glass beads and they are used in a wide range of applications (such as shot blasting, surface strengthening treatment of flying objects or special parts , plastic and rubber fillers). Microbeads in the reflective field are roughly divided into three grades : high-titanium barium, high-calcium and ordinary silicate, see the table:

No. 1 high-grade micro-beads are expensive, small and uniform particle size, high refractive index, mainly used for roadside reflective signs in . No. 2 mid-range microbeads are relatively cheap, and are used for license plates, general reflective signs and luminous markings with special reflective requirements. No. 3 is an ordinary silicate type with the lowest cost, suitable for road marking paint. According to incomplete statistics, the amount of reflective paint used in road markings in the world is about 150,000 tons every year, which is very large.

The principle of light reflective coating is to rely on the directional retroreflection of dispersed glass beads. Air is an optically sparse substance, and glass is an optically dense substance. The light is refracted by the spherical surface and reflected by the white pigment on the contact surface between the glass and the coating . Due to the directional reflection of glass beads, the reflected light is reflected to the light source along the direction parallel to the incident light. This phenomenon is called directional retroreflection. The reflective marking line paint is the use of directional retroreflection to cause the reflective effect of the marking line at night.

There are many factors that affect the reflective effect of road reflective coatings at night. In addition to the quality of the glass beads themselves , there are the following factors: the depth of glass beads embedded, the amount of glass beads scattered, the softening point of hot-melt coatings , the amount of white pigments . The particle size of reflective glass beads for road reflective coatings is relatively large, generally 0.1~1.0mm. The particle size does not require uniformity, but requires a certain distribution pattern. The average particle size is about 0.4mm, and a small amount of ellipse is allowed.