In the past, the weighing method and the dimensional geometric measurement method proposed by DERBYSHIRE were often used to measure the wear of the bearing surface of the spherical kinematic pair. To measure defects, a simple, direct and accurate method for measuring the wear on the surface of the ball is proposed: use a traditional roundness meter to measure the wear depth and wear angle of the wear part of the spherical kinematic pair, and at the same time establish a mathematical model to calculate the wear of the spherical kinematic pair Amount of wear on bumpy spherical parts. And researched and analyzed the measurement principle, mathematical model, etc., and finally came to a conclusion.

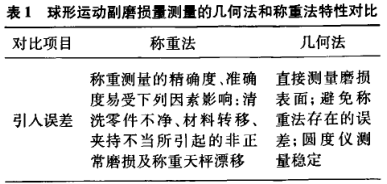

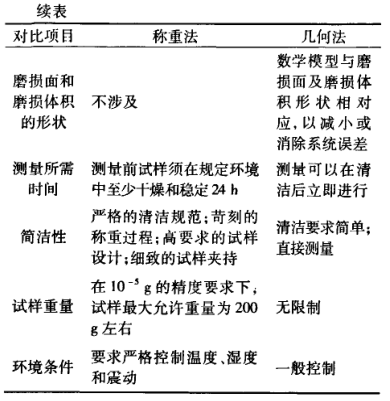

The geometric method proposed by the author is simple and direct, and can reduce or even eliminate the errors in the weighing method. Table 1 is a comparison of the characteristics of the geometric method and the weighing method.

In summary, the geometric method proposed by the author is simple and direct for the measurement of the wear amount of the spherical kinematic pair. Its advantages are high precision, unlimited size and weight of the sample, and no additional errors caused by factors such as pollution and sample fixtures.