各种漆料的黏度调配,主要是According to所用漆种的不同、用途的不同、施工方法的不同和施工季节气温的高低等因素综合考虑调配的。如涂料的标准黏度,是在25℃±1℃条件下使用涂-4黏度计进行测试的,如某种涂料产品规定的黏度为60-90秒,即指该涂料是在 25℃±1℃条件下测试的数据而言。

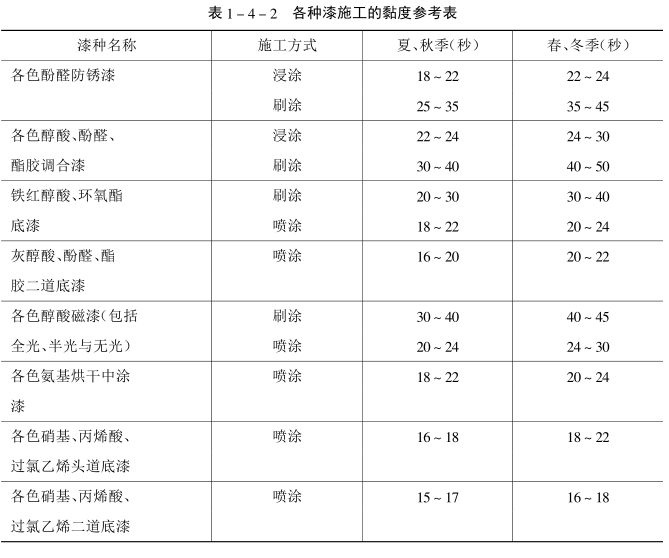

通常来说,如酚醛、醇酸防锈漆,刷涂施工黏度应调得适当大些,浸涂施工黏度应小些。对醇酸磁漆(包括全光、半光和无光)和普通氨基烘漆,其夏、秋两季施工黏度应小些,冬、春季施工黏度应大些。对硝基漆、丙烯酸漆、丙烯酸聚氨酯漆等,喷涂黏度应小于醇酸漆和氨基烘漆。另外,头道底漆、中涂漆、头道面漆的施工黏度一般应大些,而最末道面漆的黏度低些为好,以防黏度大(漆稠)喷涂的漆膜产生桔纹影响质量。

(1)调黏度前的工作准备

各种漆料在调配黏度之前,应先将该漆(清漆除外)开桶有效搅拌均匀,如包装质量在3-4 千克左右的小铁桶包装,是大开盖包装(活盖)桶,可直接掀掉大盖进行有效搅拌。对15-20千克的大包装铁桶,上部多为小盖密封(包括小包装的小盖密封桶),需要先将上部的压边死盖全部揭开或大半揭开,以便于有效搅拌,而在揭盖之前,应用毛刷将表面的浮灰等杂质扫光,再用湿布反复擦净,以防揭盖(錾子开桶时)时杂质混入漆中弄脏漆液。有效搅拌时,对颜料浆沉淀轻微的各色面漆,只要将搅漆棒插到桶底,用力均匀搅拌数次即可,对沉淀严重的防锈漆、头二道底漆,往往沉淀的颜料较多,需要用力搅拌至漆料非常均匀后,再加稀料调配黏度,以防沉淀的颜料影响涂层质量。在加稀料时,对酚醛、醇酸等防锈漆,可按清漆的用量先加10%-15%的稀料,其他在测试黏度时再逐次加入。对醇酸磁漆与氨基烘漆等普通面漆,可按用量先加15%-20%的稀料;调硝基漆,可先按用量加80%-90%的稀料;过氯乙烯漆按用量先加40%-50%的稀料;丙烯酸漆按用量先加50%-60%的稀料;丙烯酸环氧漆、丙烯酸聚氨酯漆先按用量加 30%-40%的稀料;

对丙烯酸金属漆色浆,按用量先加20%-30%的稀料,罩光清漆加10%-15%#稀料 etc.。

After adding thinners to various paints, stir again thoroughly, then test with a viscometer, and add thinners or paints one by one according to the viscosity required by the construction until the viscosity meets the requirements. For various two-component paints, the curing agent should be mixed with the paint first, and then thinner should be added to dilute to the viscosity . After the viscosity is adjusted to pass, filter and clean with a suitable sieve, and then construction can be carried out. For various imported two-component automotive coatings, the scale equipped with the coating can be used for deployment, and there is no need to use a viscometer for testing.

(2) Viscosity reference for various paint construction

(3) Precautions for viscosity adjustment

Pay attention to the following items when adjusting the viscosity:

When adjusting the viscosity, due to the great difference in the temperature of different regions in different seasons, it cannot be stereotyped, and it should be flexibly controlled according to the actual temperature of the construction site.

The thinner used for viscosity adjustment needs to be matched with the paint type, and cannot be used wrongly, so as not to affect the thinning ability or even cause the paint to deteriorate.

After the viscosity of various paints is adjusted, they should be filtered into clean and dry containers for storage. The containers should be free of moisture, oil and other impurities, so as not to affect the cleanliness of the paints or the quality of the coating.

Before adjusting the viscosity, you should first estimate the amount of paint used for the car, and then adjust according to the amount. Especially for two-component paints, do not mix too much at one time to prevent gelling and scrapping.

After the viscometer is used, it needs to be cleaned with thinner.