According to the requirements of JJG905-1996 "scraper Fineness Meter" verification regulations, according to the verification project program table, before verifying the error of indication of scraper, the flatness and transverse straightness of scraper must be verified. On the premise of confirming that the error conforms to the regulations, the error of indication verification of the depth of the scraper chute is carried out. Because the error of the upper plane and the bottom plane of the scraper and the horizontal straightness of the scraper will directly affect the correctness of the error of indication. The error of indication of scraper is verified by vertical Optical inspectIon Meter, and the error of indication should be verified in each engraved line position.

As shown in Figure 1, the scraper is placed on the workbench of the vertical Optical inspectIon Meter, so that the probe of the vertical Optical inspectIon Meter is in contact with point A at a certain engraved line position, and according to the requirements of JJG882-2004, The sexual repeability takes the data of 3 cycles; and according to the author's understanding, the sexual repeability data should take the data of 6 upper or lower strokes. The specific data and calculation results are shown in Table 1.

It can be found that the laboratory standard deviation s calculated according to JJG882-2004 is almost 3 times larger than the s ′ calculated by the method in this paper, which will relax the requirements for standard equipment and sex repeability assessment. Although the final uncertainty sub-items u (I2) and u ′ (I2) are relatively close, there is a process of zooming in and out in the method of JJG882-2004. The author believes that the entire evaluation process is inappropriate.

Figure 1 Scraper error of indication verification

Adjust the instrument to zero, then move the scraper to bring the probe into contact with the left i1 point of the groove, and read the actual depth Li1 of this point on the vertical Optical inspectIon Meter. The error of indication of scraper is calculated as follows:

δi1=Li1标- Li1

式中:δi1—The indication of the error of the scraper at this point,μm; Li1标—The nominal value of the scraper at this measurement position, μm; Li1—The actual depth of the scraper chute at that point, μm。

In the same way, measure the error of indication δ i2 at point i2 on the right side of the groove, and take the larger error in δ i1 and δ i2 as the error of indication of the measurement position. Gradually move the scraper to measure the actual depth of each reticle of the scraper, so as to obtain the error of indication of each point of the Fineness Meter of the scraper.

Example: According to this method, a scraper Fineness Meter is randomly selected for relevant verification. Its manufacturer is PRECISION GAGE & TOOLCO, and the specification is (0~ 50) μm.

1. Flatness and straightness verification

The flatness of the upper plane and the bottom plane of the chute of the scraper is 2 μm, and the transverse straightness of the upper plane is 1 μm, both of which meet the requirements of the regulations. The flatness is not more than 3 μm and the straightness is not more than 1 μm.

2. Scraper error of indication verification

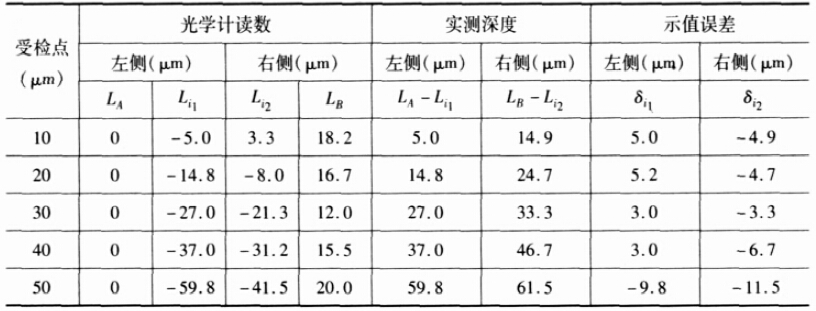

According to the specified method of verification, with JD3 vertical Optical inspectIon Meter verification, verification records as shown in Table 1.

After processing the data in Table 1, if the measured error of indication exceeds the requirement of ± 2.5 μm for the error of indication of the Fineness Meter of the scraper with a measurement upper limit of 50 μm in the specification, it is judged that the error of indication of the scraper is unqualified. However, judging from the verification results of flatness and lateral straightness and normal observation, the scraper should not have this result.

Table 1 Optical inspection verification error of indication measurement

For more information, please refer to the full text of "Discussion on the error of indication method of scraper Fineness Meter" (Lu Miaoshi)