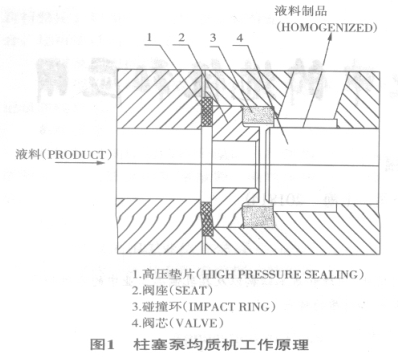

Plunger pump high-pressure homogenizer is a kind of deep processing equipment. This function is mainly completed by high-pressure homogeneous valve. Its structure is shown in Figure 1: it is composed of valve seat, valve core and collision ring.

It can be seen in Figure 1 that when the high-pressure liquid material enters the inner cavity of the valve seat, when its pressure exceeds the pressure formed under the action of the preset high-pressure spring, the valve core moves to the right, and the valve core and the valve seat are opened, forming a gap between the valve core and the valve seat. A very small gap, about ≤0.4mm, high-pressure liquid flow at a very high linear velocity (usually up to 200-300m/s), when passing through this gap, the liquid material will produce a huge pressure drop, instantaneous pressure loss, expansion, explosion ( This complex process is called the cavitation effect), which produces high-frequency vibration and turbulent flow, forming a strong shear effect and a collision effect formed by high-speed impact in the collision ring, among which the cavitation effect plays a leading role, and there will be particles or Oil droplets are crushed into very small sizes, diameter φ0.01~2μm, average φ≤1μm, and more satisfactory emulsion or homogenate can be obtained. This process actually integrates the functional principles of ultrasonic homogenizer (cavitation effect), high-speed shearer (shear effect), jet homogenizer (collision effect), etc. It can be seen that its efficacy is far from than other devices. Its products maintain the original activity, stability, and mixing. After homogenization, dairy products have better nutritional value, easy absorption, shelf life, taste, and color. Therefore, it has been recognized as an effective, energy-saving and reliable ultra-fine grinding, emulsifying and homogenizing equipment at home and abroad for more than one hundred years.

Generally, the homogenizer has a two-stage homogenizing valve. The second-stage homogenizing valve is the second-stage homogenizing valve (or low-pressure valve). Its function is mainly to give a suitable back pressure to the first-stage high pressure, concentrate the energy of the first stage, and make the cavitation effect occur in the gap. At the same time, after the first level of homogenization, the particles may be aggregated and broken again due to the force of van der Waals gravity, and the feed liquid is further emulsified and homogenized.

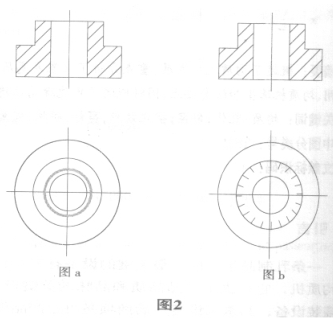

The area where the cavitation effect occurs depends on the size of the back pressure, the structure of the valve and the viscosity of the liquid material. If the back pressure is too small, the area where the cavitation effect occurs will move to the exit of the gap, which may cause the cavitation to be out of control, and the outer edge of the valve seat will easily collapse and be damaged; If it is too high, it will also cause less cavitation effect, which will affect the homogeneity effect, and the inner wall of the valve seat hole will be easily collapsed and damaged. So the cavitation effect needs to be also controlled. When the cavitation effect occurs, local high temperature and high pressure will be generated, which will cause cavitation gas melting, and gradually make the working end faces of the valve seat and valve stem of the homogenizer rough. According to this roughness, it can be judged that the cavitation effect is controlled. Still out of control. If it is well controlled, a closed ring should appear on the corroded and rough end face (as shown in Figure 2a).

If it is observed that the local roughness on the working surface is radial, it means that the holes are out of control (as shown in Figure 2b), and the energy cannot be fully utilized at this time. Therefore, the second-stage homogenizing valve is connected in series after the first-stage homogenizing valve, and changing the gap size of the second-stage homogenizing valve can change the back pressure of the first-stage homogenizing valve; at the same time, it prevents the dispersed particles from re-aggregating.

A good back pressure should be obtained through experiments. In practice, the good back pressure of milk homogenization should not be greater than 20% of the homogenization pressure. In fact, due to the complexity of the milk production pipeline, considerable back pressure has been formed. In this way, it is impossible to obtain the required lower back pressure, or even lower the back pressure. Therefore, some homogenizers have only one homogenizing valve, which utilizes hydraulic characteristics to form a certain back pressure.

Since the second-stage homogeneous valve mainly concentrates the energy of the first stage, no collision ring is installed structurally. For example, in production practice, generally the low pressure of milk is about 2MPa (20Bar), the high pressure is 16~18MPa (160~180Bar), the low pressure of yogurt is about 2~4MPa (20~40Bar), and the high pressure is 20~25MPa (200~250Bar). , in principle, in order to achieve the homogeneous effect, it is better to take a lower value for the pressure. The homogenization temperature has a great influence on the homogenization effect. The higher the temperature, the higher the saturated vapor pressure, and the cavitation effect is easy to form during homogenization. Temperature is beneficial. In actual production, the homogenization temperature of milk is generally 50-70°C, and 50°C is the lowest temperature for effective homogenization of milk. If it exceeds 70℃, air pockets will be generated in the equipment, the work will not work normally, and the pressure pointer will swing greatly. A higher temperature can promote the pulverization and dispersion of fat globules, but it is not conducive to thermal stability. The above needs to be practiced by manufacturers in various places under the guidance of technicians to obtain good homogeneous pressure data.