Fundamental

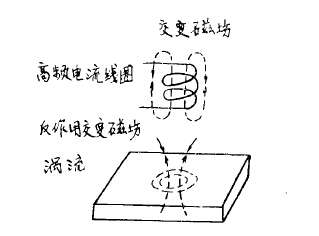

As shown in Figure 1, the inner coil carrying a high-frequency current generates a high-frequency magnetic field in its surrounding space. If the metal conductor is placed in this high-frequency magnetic field, an eddy current will be generated in the metal conductor under the uniform action of the magnetic field, and the eddy current will generate The magnetic field reacts against the excitation coil about the magnetic field to change the impedance of the coil. The change of coil impedance is related to the magnetic permeability, electrical conductivity, geometric shape of the metal, the geometric shape of the coil, the frequency of the current carried, and the distance between the metal conductor and the excitation coil. If the other parameters are kept constant so that the coil impedance is only related to the distance, the eddy current method can be used to measure the thickness of various coatings on refractory metals.

Figure 1 Schematic diagram of eddy current generation

structure and performance

The eddy current Thickness Gauge is made entirely of transistors, and is divided into six parts, namely, voltage-stabilized power supply, 2Mf oscillator, probe resonant circuit, isolation circuit, broadband amplifier, and indicating circuit. The physical photos are shown in Figure 2.

The instrument is divided into four gears, the total range is 0-700 microns, and the sensitivity is ±2 microns. The probe is equipped with a spring device to keep the relative pressure between the probe and the measured object constant during each measurement, so as to ensure the accuracy and stability of the measurement.

This Thickness Gauge is basically used for coating thickness measurement on flat plates, and it can also be applied to curved surfaces with a curvature radius greater than 20 mm. But for parts with complex shapes, especially the edge parts, it is limited due to magnetic field distortion. The eddy current Thickness Gauge can measure not only the thickness of the coating after sintering, but also the thickness of the coating (slurry) before sintering, so as to ensure the uniformity of the sintered coating. It can be used in the study of oxidation mechanism. The increase of oxide film thickness is related to exposure temperature and time. When the sample is taken out of the heating furnace for thickness measurement, the regularity of oxide film thickening can be found. Thus, the antioxidant lifetime can be predicted.

For more information, please refer to the full text of "Nondestructive Testing of High-temperature Hang Oxidation Coatings" (Baoji Institute of Nonferrous Metals)