1. Roller brush

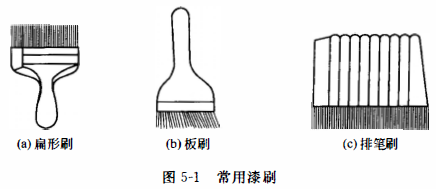

There are many types of paint brushes (see Figure 5-1), and the brush heads are mainly made of pig fur, wool, ponytail, wolf hair, human hair, brown silk and synthetic fibers. Hard-bristle brushes are mainly used in the construction of floor coating, made of Zhuchong, which must meet the requirements of the QB 1103 standard. Due to the small amount and high price of pigskins, paintbrushes made of synthetic fibers such as nylon filaments have been widely used. Their elasticity and recovery are not worse than pigskins, and they are more wear-resistant. When choosing a paintbrush, it is required that the front end of the brush head is neat, soft to the touch, free from broken hairs, falling hairs, and no hair shedding. If the brush head is not separated after being soaked in a solvent, it is a good paintbrush.

(1) Use of paint brush Before use, the new paint brush should be rubbed back and forth on the emery cloth to smooth the bristles, and the bristles should be straightened up several times to remove the residual hair and dust in the bristles. Generally, the primer and enamel are applied with a hard brush, and the varnish is applied with a scrub brush with thinner bristles and better elasticity.

The paintbrush is generally used with a straight grip method. Hold the paintbrush tightly with your hand, rotate the paintbrush with your wrist, and cooperate with the movement of your arms and body. When picking up the paint with a paint brush, the brush head immersed in the paint should not exceed half the length of the bristles. For the paint brush with paint on it, gently wipe the inner wall of the paint bucket a few times to wipe off the excess paint. Paint brushes need to be cleaned effectively with thinner after use. If the construction is only intermittent, hang the cleaned paint brush vertically in the corresponding thinner, immerse the brush head below the liquid level, but do not allow the bristles to touch the bottom of the container, causing deformation of the brush head.

(2) Brushing method The quality of brushing mainly depends on the actual experience and proficiency of the operator. Before brushing, it is necessary to fully stir the components of the paint evenly, accurately prepare and stir evenly according to the proportion, and filter out the impurity particles with a filter. The paint viscosity required by brushing is relatively wide, generally 20-50s (paint-4 cup Viscosity Cup, 25°C) is appropriate, and adjusted with a special thinner.

Brush in one direction first, and then brush in a vertical direction until the coating film is flat and free of bubbles, and a continuous coating film with a relatively uniform thickness can be obtained. When brushing the ground, apply the last coat. If it is carried out according to the direction of light irradiation, the visual effect of the appearance can be improved. The requirements for brushing the ground are: no flow, no wrinkle, no leakage and no brush marks.

2. Roller

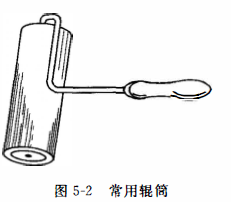

The stick (see Figure 5-2) is a hollow cylinder, and the surface of the ordinary stick is pasted with plush made of wool or synthetic fibers. The fluff length of the sleeve of ordinary sticks has three specifications: long, medium and short. The sleeves of the medium and long-pile sticks have a lot of paint attached to them, and are suitable for rough surfaces. These two kinds of sticks are often used when applying floor coatings.

There are many types and specifications of rollers, and special-shaped rollers can be coated with various patterns and shapes of coating films.

(1) Use of sticks New sticks should be cleaned and shaken repeatedly before use to remove residual dander and dust. When sticks are applied to the floor, it is generally necessary to add long handles such as bamboo poles and wooden sticks of appropriate length to the handle. , so that a larger area can be painted. Clean the new stick with thinner.

It is better to dry the thinner and then pick up the paint for construction. If the used roller needs to be reused for a short time, it can be simply cleaned and soaked in thinner or one-component paint. After the project is completed, it should be cleaned with thinner. The cleaning method is: scrape off the attached paint with a scraper, soak it in the thinner, roll it on clean waste such as waste paper, squeeze out the paint liquid and thinner, and repeat this several times until the natural color of the fluff is exposed. sleeve, loosen the intertwined fluff and store away.

(2) Rolling coating method: first soak 1/3-1/2 of the stick into the prepared paint, roll it on the inner wall of the container, soak the stick into the paint, and squeeze out the excess paint at the same time. Roll gently in a W shape, roughly distribute the paint on the floor, first apply it with a stick in one direction, and then roll it in a vertical direction when the paint on the stick is basically used up. Flatten the paint with uneven thickness until it is uniform in thickness. When stick coating the last top coat, it should stick in the same direction (such as the direction of light irradiation).

The requirements for stick coating the ground are: no heap, no leakage, no rolling marks and joints.

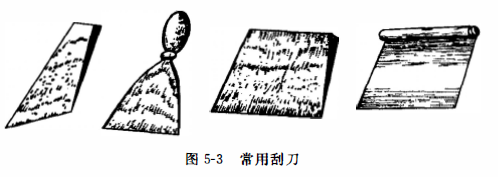

3. Squeegee

Special tools for scraping and coating are made of metal, rubber, bamboo, horn and plastic. Commonly used is a metal scraper. The metal scraper has the characteristics of toughness and durability, and is mostly used for filling putty in floor coating. The common types are shown in Figure 5-3. In fact, flat knives (commonly known as trowels) are most used in floor coating construction, which is suitable for scraping putty and floor coatings on large areas.

(1)刮刀和平刀的使用刮刀的选择是否得当,对刮涂效率和 质量有直接影响。选择刮刀和平刀的板面应平直,刀口不必太锋利,但要平直,不能有缺口。新刮刀和平刀要用砂纸打磨刀口,除去毛刺。夏天气温较高时使用,每隔适当时间应更换一次,避免弯曲变形。冬天气温低时使用,不可用力过猛,防止断裂。使用后要及时擦拭干净,沾有腻子或涂料的刀具用另一刀具除去沾附物,再 用相应溶剂擦拭干净。刀口磨损或有毛刺时应及时研磨修理。

(2)刮涂方法用专用稀释剂调节刮涂物料的黏度,有时也可 以加入少量同类性质的色漆(地坪面漆),搅拌均匀后刮涂。刮涂 时用力按住刮刀,刀口紧贴地面,使刮刀或平刀倾斜成一定的角 度,顺着地面刮平。满批腻子或中涂料时,左右来回,反复刮涂, 注意搭接处用刀收平整。如果左右用力不均或者刀尖用力不当,就会产生接缝或条纹。

刮涂地面的要求:平坦、光滑、坚硬。

4.幔刀

镘涂施工专用工具。一般为金属材质制作,其形状和尺寸大小与平刀类同,只是刀口为锯齿状,齿长从1-5mm不等。当操作手法一样时,镘刀齿长与施工的涂膜厚度成正比关系。镘刀选择是否得当,会直接影响施工效率、涂膜质蜇、涂膜厚度和材料用量。

(1)镘刀的使用按镘涂厚度要求选择齿长合适的镂刀,镘涂1mm厚度的涂膜,一般选择2mm齿长的俴刀。镘刀的板面应平整,刀口要平直,不能有缺口或少齿。使用后的镘刀擦洗干净。由于锯齿状刀口很容易沾污,更应及时清理,用另一刀具剔除齿间污 物,用溶剂有效擦拭干净,并妥善保管。

(2)镘涂方法镘涂主要用于尤溶剂自流平地坪涂料施工。将 涂料各组分分别搅拌均匀,按比例调配并充分搅拌,用过滤网过 滤,除掉杂质颗粒,倒于镂涂起始位置的地板上,先镘涂边角,再 用力按住镂刀,使其与地面倾斜成一定角度,顺着地面刮平。左右 来回反复刮涂,注意将搭接处用刀收平整。如果左右用力不均或者 刀尖用力不当时,会产生接缝或刀痕。

镘涂自流平地坪涂料时,要求地板表面平整和水平。镘涂地坪 质量要求:平整、光滑、均匀、无刀痕和接口。

5.空气喷涂设备及工具

(1)空气喷涂装置

①Spray gun, atomize the paint and spray it on the ground;

②Air Compressor, compressed air supply and purification system, supplying clean, dry, oil-free compressed air;

③ Paint storage tanks, paint storage, continuous paint supply;

④Rubber hose, conveying compressed air.

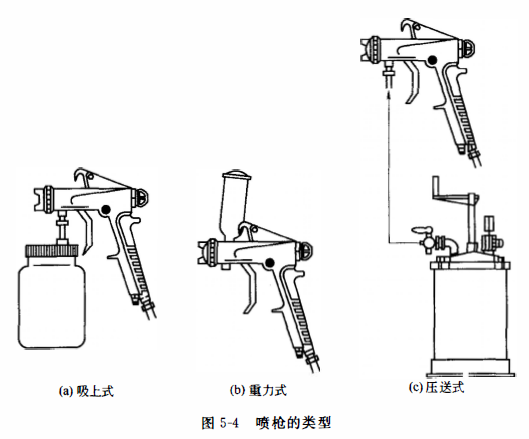

The Spray Gun is the main tool for mixing the paint and compressed air, and spraying the paint on the ground after atomization. There are many types of Spray Guns, which are classified according to the paint supply method. There are mainly three types: suction type, gravity type and pressure-feed type, as shown in Figure 5-4. Their characteristics are listed in Table 5-1.

(2) Use of air Spray Gun

①The appropriate Spray Gun and nozzle size should be selected. The relationship between general paint and nozzle: for low viscosity paint, the nozzle diameter is 1~1.5mm; for high viscosity paint, the nozzle diameter is 2??3mm; for putty, the nozzle diameter is 3.5??4.5mm. The relationship between the spraying object and the nozzle: spraying a small area, the nozzle diameter is 1~1.5mm; spraying a large area, the nozzle diameter is 2.5~3mm; spraying various patterns and characters, the nozzle diameter is 0.2~1.2mm.

The distance between the Spray Gun and the surface of the object to be coated has a great influence on the quality of the coating film. If the distance is too close, the paint layer will thicken and produce orange peel; if the distance is too far, the coating film will become thinner, the loss of paint will be large, the coating film will be uneven, and the gloss will be greatly reduced in severe cases, and the coating film will easily fall off. Generally, the spray distance is controlled at 20~30cm.

The spraying pressure can be adjusted according to the size of the nozzle and the nature of the paint. Generally, high-viscosity coatings use higher pressure, such as putty spraying, the pressure is generally 0.35 MPa; the pressure of high-viscosity materials is 0.25-0.3 MPa; the pressure of low-viscosity materials is 0.1-0.15 MPa.

If the air pressure is too high, although the atomization is fine, the paint will scatter a lot and the loss will be great. Conversely, if the pressure is insufficient, the spray will become thicker, resulting in defects such as orange peel and pinholes.

②The paint should be properly prepared before spraying. Two-component coatings should be mixed evenly and have a certain pot life. Paint needs to be filtered. Paint viscosity needs to be adjusted with thinner. If the viscosity is too high, the atomization will not be good, and the coating film will be rough and dull; if the viscosity is too small, it will be easy to float and so on. The suitable paint viscosity is 16~35s (coating - 4 cups). When filling the paint storage tank, do not overfill it, preferably 2/3.

③When using the Spray Gun, press the trigger with your index finger, so that the channel of compressed air will be opened first, and then the channel of the paint nozzle will be opened. Compressed air is piped to the spray head, and the paint is sprayed from the nozzle and applied to the surface. When the trigger is released, the small hole of the nozzle is tightened by the thimble