With the continuous development of color coating technology, the current measurement and control technology of film thickness basically forms three types, namely, post-line dry film feedback adjustment type, wet film prediction adjustment type and online instrument measurement type. The first one is to guide the online data of the production line through the actual dry film data of the finished product. Obviously, this method has the characteristics of hysteresis, which is easy to cause the quality of the product to decline, and cannot play a role in guiding production in time. It is a relatively backward method. The online instrument measurement method uses the principle of the difference in conductivity or emissivity between metal and non-metal, and uses the online continuous measurement of the instrument to indirectly convert the film thickness, so it can well overcome the shortcomings of the previous method. Achieve the effect of online measurement and adjustment. However, due to the high investment and the influence of many factors, this method is suitable for guiding on-line production, but it is difficult to achieve accurate measurement, the error is large, and there are still many technical problems unsolved, so it is not suitable for most current color plate manufacturers. Film thickness online control.

The wet film prediction and adjustment method is a film thickness control method commonly used by most color plate manufacturers and can be quickly promoted. It uses the volatilization principle of the coating, that is, the principle of the dry film after the volatile components of the coating are removed. In actual production, The wet film thickness can be deduced from the dry film thickness and solid content, so that the purpose of controlling the dry film thickness can be achieved by controlling the wet film thickness. For example, if the volume solids content of the paint is 50% and the target dry film thickness is 15 μm, then the target wet film thickness can be quickly calculated to be 30 μm according to the general relationship between dry film and wet film in formula (1).

Dry film thickness (DFT) = wet film thickness (μm) x coating volume solids content (%) (1)

But in practice, it is found that the value calculated according to this formula is very different from the actual value, and it can only play a guiding role in the production trend. Analyzing the reasons, first of all, there is a large deviation in the volume solid content itself as a key parameter. Because this value is usually calculated by the paint supplier through the measured value of the weight of solids in the paint production, and then the paint is put on the line and undergoes multiple processes such as viscosity adjustment, so this value and the above film thickness calculation are only theoretical , or the test methods stipulated in some standards such as ASTM D 2697, the deviation is relatively large.

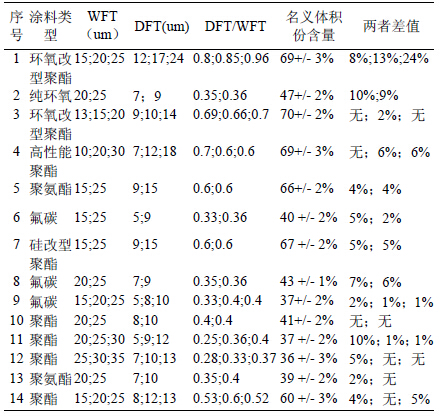

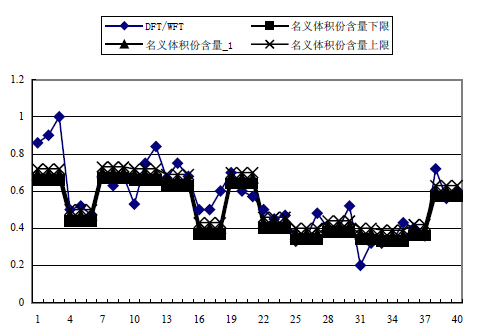

Therefore, to use this method for film thickness control, it is necessary to first realize the correction of the wet film calculation formula. In order to achieve this correction, the data of the production line is used for analysis and research, and the difference and trend of different suppliers, different volume content and different types of coatings are compared. By comparing the actual wet film thickness of the production line with that of the laboratory, and then use a magnetic Thickness Gauge to measure the dry film thickness of the corresponding color plate roll and sample for record comparison. The coatings used in this analysis data are 14 kinds of solvent-based coatings with different volume solid content provided by five well-known suppliers. The roughness in turn ensures that the influence of substrate roughness in the analysis data is as small as possible. Combined with the actual production, in the normal production process of the coating after using the diluent, the wet film and dry film are measured respectively, and the ratio is compared with the volume solid content measured in the laboratory. The analysis results are shown in Table 1 and Fig. 1, it can be seen from the analysis chart that the actual ratio on the production line has a large deviation compared with the traditional calculation method formula (1); only from the difference in volume solid content, it can be clearly seen that the deficiency of formula (1). Considering that the online strip wet film measurement error is relatively large, which may cause the deviation of the final results in Table 1, the above-mentioned analysis and comparison were carried out on the samples obtained by scraping rods in the laboratory, and the wet film thickness was measured using a plate-shaped gear-shaped wet Film Thickness Gauge. Measurement and analysis results are shown in Table 2 and Figure 2.

Table 1 Comparison table of dry-wet film ratio and volume solid content of production line

Fig.1 Comparison chart of nominal volume solid content and measured calculated value

Table 2 Comparison table of dry-wet film ratio and volume solid content of laboratory samples

Figure 2 Comparison chart of nominal volume solid content and laboratory calculation value

It can also be seen from the above table that the calculation of the film thickness in the laboratory according to the traditional calculation method also has a large deviation and the deviation is irregular. However, the volume solid content of the same method in the laboratory and production line is quite different from the value calculated by back-calculation. It can be seen from this that the deviation of using the traditional calculation formula method is very large, and the main influence is the upper-line accurate value of the volume solid content.

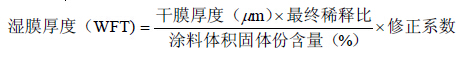

The reason for this is mainly because there is still a part of the solvent that has not yet volatilized in the actual state, resulting in a thick or uneven film thickness; or the influence of the diluent. Therefore, in order to achieve accurate prediction and control of film thickness, this problem must be solved first. Some foreign high-end color plate manufacturers calculate the dry and wet film thickness after adding diluent based on experience. The formula is to record the amount of diluent added into the formula. For example, if the target value of the dry film thickness is 100um, and the solid content of the original volume of the paint is 35%, in order to achieve the required viscosity, an average of 0.5 liters of thinner is added to every 5 liters of paint, and the paint can be calculated. The volume dilution ratio is 10%. According to the formula (2), assuming that the correction factor is 1, the wet film control thickness will reach 314 um. In practice, the correction coefficient needs to be analyzed and summarized based on empirical historical data to obtain the formula (2) correction relationship between dry film and wet film:

For more details, please refer to the full text of "Research on Film Thickness Accurate Measurement and Predictive Control Technology on Color Coating Production Line" (Xing Chang, Song Chengge)