Abstract: This paper summarizes the definition and understanding of VOC in different countries and regions, introduces the current situation of VOC emissions and related policies and regulations in the domestic coating industry in the application fields of automobile original factory, automobile repair, furniture manufacturing, engineering machinery, shipbuilding, etc., and discusses the feasibility At the same time, the relevant VOC limits in relevant domestic policies and regulations were compared with those of other countries, and the future development direction of VOC control in the coatings industry was proposed.

0 Preface

Since the 21st century, CHINA's economy has developed rapidly. In 2011, it officially surpassed Japan to become the country with the second highest GDP in the world. The economic miracle created by CHINA has amazed the world. However, there are still many hidden worries behind the halo, among which environmental problems are the most serious. In response to environmental problems, my country has strengthened the supervision and control of environmental pollution from all walks of life, and formulated and implemented a series of related policies and regulations as a solid theoretical basis and legal guarantee. For one of the important industries of my country's industrial development, while the coatings industry is constantly promoting the development of my country's manufacturing industry, its huge amount of pollution has also become the country's heart disease. I hope that the summary and comparative analysis of this article can help the country further formulate Relevant policies play a positive role.

1 VOC definition

At present, the management of VOC in CHINA is divided into different angles. From the perspective of physical properties, there are two expressions: vapor pressure (0.01 kPa) and boiling point (250 °C or 260 °C), which are mainly used in the industry. For VOC products (such as coatings, ink, etc.) for description or testing. From the perspective of environmental protection, there are two expressions in the narrow sense (such as photochemical reactivity, health toxicity, odor, etc.) and in the broad sense (all gaseous organic compounds), which are mainly used in the environment. As pollutants, VOCs reflect their health and environmental effects . From the perspective of detection methods, there are N MHC (HJ/T 38-1 999 non-methane total hydrocarbon measurement method) and TVOC (GB/T 1 8883-2002), which focus on operability and measure certain organic compounds.

1.1 Definition of VOC in the United States[1]

Any carbon compound that participates in atmospheric photochemical reactions, except CO, CO2, H2CO3, metal carbides or carbonates, ammonium carbonate. The definition is accompanied by 7 supplementary clauses that need to exclude organic species with negligible photochemical reactivity

Compounds, such as methane, ethane, dichloromethane, acetone, tetrachloroethylene, etc. 5 2 kinds (continuously updated).

1. 2 EU VOC definition

All organic compounds (2 0 0 4 / 4 2 / EC) whose initial boiling point is less than or equal to 2 5 0 ℃ at the standard pressure of 1 0 1 . 3 kPa.

1.3 Definition of WHO TVOC

A general term for volatile organic compounds (except pesticides) with a melting point below room temperature and a boiling point between 50 and 260°C (WHO 1989).

2 Development of my country's coating industry and VOC situation at the present stage

From January to June 2016, the output of my country's coating manufacturing enterprises above designated size reached 8.4149 million tons, a year-on-year increase of 6.43%. Compared with the ranking of the "Annual Report on the Paint Industry (2015 Edition)", the top three are still: Guangdong Province, with an output of 146.91 million tons, a year-on-year increase of 1.88%; Jiangsu Province, with an output of 109.79 million tons, a year-on-year increase of 2.54%; in Shanghai, the output was 916.8 million tons, a year-on-year increase of 0.16%. While the paint industry continues to flourish , it also brings huge VOC emissions. At present, nearly 60% of CHINA's paint industry is solvent-based paint, and solvent-based paint will volatilize a large amount of toxic substances during the production process. More than half of the VOCs in the painting process will be directly emitted into the atmosphere.

3 VOC emission status, applicable regulations and feasible technical solutions for emission reduction in various application fields of coatings

3.1 Automotive original paint

3 . 1 . 1 The use of automotive original coatings and the status quo of VOC treatment

On November 4, 2011, the Ministry of Industry and Information Technology issued the " Passenger Vehicle Manufacturers and Product Access Management Rules", requiring passenger vehicle manufacturers to meet the requirements of clean production and have the necessary environmental protection and professional qualifications. Safety and health equipment and facilities. The "Twelfth Five-Year Plan for Air Pollution in Key Areas" approved by the State Council on September 27, 2012 (Huan Fa [2 0 1 2] No. Control is an important part of environmental impact assessment of construction projects, and strict : new motor vehicle manufacturing and painting projects, water -based paints and other low-VOC paints account for no less than 80% of the total paint usage, and small vehicles The VOC emission per unit painted area of the vehicle shall not be higher than 35 g/m 2 [2]. Therefore, in recent years, the water-based and water-based compact process of automobile original coatings has been vigorously developed. In addition to clear varnishes, primers, mid-coats, and base coats can all be water-based. In the coating process, most uses RTO, TAR device or quaternary burner, while most of the coating part is discharged directly, and a small number of enterprises adopt the method of concentration runner and combustion to collect and treat.

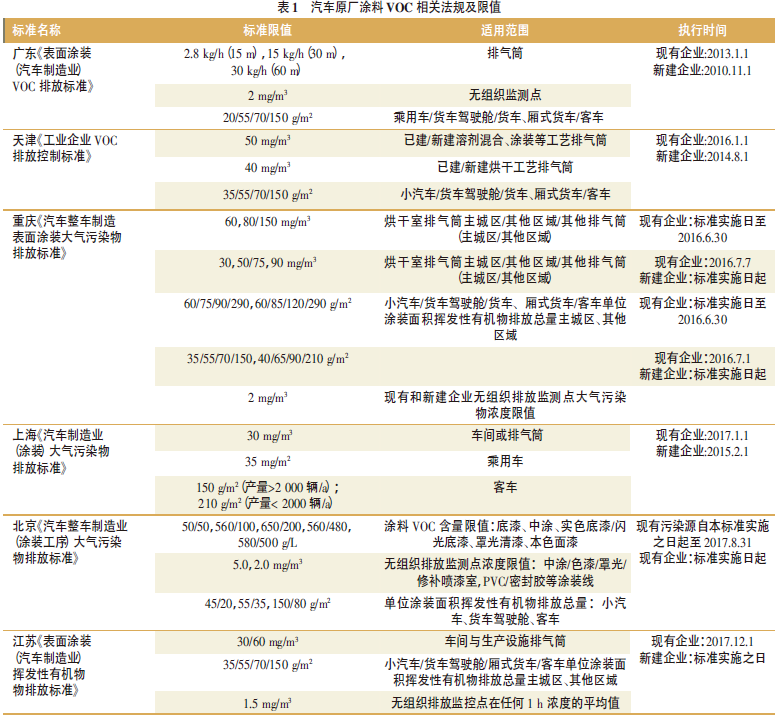

3 . 1 . 2 Relevant regulations on VOC in automotive original paint and its limit value

See the figure below for the relevant regulations and limit values of VOC in automotive original paint.

3 . 1 . 3 Feasible technical solutions for emission reduction

Combining source control and process management, for new automobile coating production lines, choose high solid content 3 C 1 B, water-based 3 C 1 B, water-based primer free, etc.

Coating process with the ability to meet emission standards. Automobile coating production line has been built

It is economically feasible to carry out transformation and upgrading, transforming to high solid content 3 C 1 B process, the transformation period is short, the construction is simple, the investment and operation cost is low, and the

Ability to meet discharge standards. Improve spraying automation and increase robot inner panel spraying to improve coating efficiency. Deepen the VOC terminal treatment of solvent-based paint spraying, build a solvent recovery system, and establish a waste gas VOC treatment system [3].

3.2 Automotive refinish coatings

3 . 2 . 1 Application of automotive refinish coatings and status quo of VOC treatment

虽然汽车修补涂料在整个涂料市场占比份额不

大,但是由于汽车修补施工过程大部分为无组织排放,

且其为民生工程,因此汽车修补行业产生的 V O C 对环境的影响不容小觑。汽车修补涂料中色漆水性化比较成熟,中涂、底漆及清漆由于涂料技术及施工便捷性的影响依然以溶剂型为主。

3 . 2 . 2 汽车修补涂料国内外法规对比分析

主要地区汽车修补涂料 V O C 法规限值见表 2 。

由于在不同的法规中对是否去除水来计算 V O C方法不一,造成有些法规限值相差较大。北京、深圳的地方标准中 V O C 限值的规定在借鉴国外相关法规的同时,考虑了中国的国情并充分听取了国内企业的意见,这点值得提倡。后续希望对特殊涂料领域如亚光清漆、底盘涂料、瑕疵修复涂料完善相关法规。

3 . 2 . 3 减排可行性技术方案

为了达到降低 V O C 的目的,色漆可以实现水性化,中涂和清漆则可以通过改用高固含涂料来实现。高固含涂料的使用与溶剂型涂料相同,无需喷涂工艺上的改变,但是为了配合水性色漆的升级换代,需要对设备、施工工艺进行调整。增加喷涂设备如带气压表的水性漆专用喷枪和专用吹风装置,改善施工环境,对基材进行前处理,严格调配比例,使用正确的调枪方法和灵活的喷涂手法。

3 . 3 家具涂料

3 . 3 . 1 家具涂料使用情况及 V O C 治理现状

国务院 2 0 1 2 年 9 月 2 7 日批复实施的《重点区域大气污染“十二五”规划》(环发[ 2 0 1 2 ] 1 3 0 号)中指出:家具等行业新建涂装项目,水性涂料等低挥发性有机物含量涂料占总涂料使用量比例不低于 5 0 % ,禁止生产、销售、使用挥发性有机物含量超过 7 0 0 g / L 的溶剂型木器家具涂料。

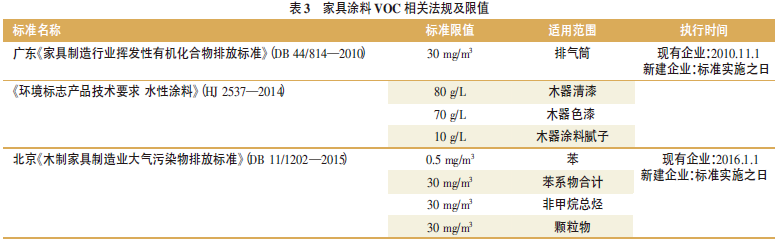

2 0 1 4 年 3 月 3 1 日国家环保部修订了 H J / T 2 0 1 —2 0 0 5《环境标志产品技术要求 水性涂料》发布了对水性涂料新的环境标志产品的技术要求 H J 2 5 3 7 —2 0 1 4《环境标志产品技术要求 水性涂料》,这些都大大推动了家具涂料的转型升级,各个涂料生产企业为了提高产品竞争力,对产品中 VOC 及限制物质又做了进一步改进以满足客户对于不同国家法规或绿色环保产品的要求。

同时也应该看到,家具制造企业 80% 以上为小型企业,集中度低,涂装工艺差异较大,仅有部分大中型家具企业采用水性涂料与收集后处理装置,小型企业家具制造过程中的排放比较无序,缺乏监管。 3.3.2 家具涂料 VOC 相关法规及其限值

家具涂料 VOC 相关法规及限值见表 3。

3.3.3 减排可行性技术方案

对于平面板式木质家具,推广使用 U V 涂料、水性涂料等低 VOC 含量的涂料,配套使用辊涂等有效涂装技术。对于形状不规则的木质家具,可实施部分或全部水性化,溶剂型涂料应密闭喷涂,配套建立有机废气收集及燃烧、吸附、吸收等末端处理装置。

3 . 4 工程机械涂料

3.4.1 工程机械涂料使用情况及 VOC 治理现状

工程机械制造企业集中度高,以大型企业为主,但是目前普遍采用溶剂型涂料,且多数构件形状不统一,无法实现自动化涂装。部分处于环保严格地区的企业实现有组织收集后处理,并试用高固含涂料。

3.4.2 减排可行性技术方案

由于工程机械制造厂自动化程度较低,涂装环节较汽车涂装差,水性化不是非常适用,而升级使用高固含涂料从设备到施工工艺都不需要进行大的改造,更适合工程机械涂装行业。

3.5 船舶制造涂料

3.5.1 船舶制造涂料使用情况及 VOC 治理现状

船舶制造企业规模较大,涂装 VOC 排放集中度高,但是船舶涂料均为溶剂型涂料,分段涂装所用涂料量占比较大,不同船舶分段数量与大小不同,船舶越小分段越少,单位吨位排放量越大。

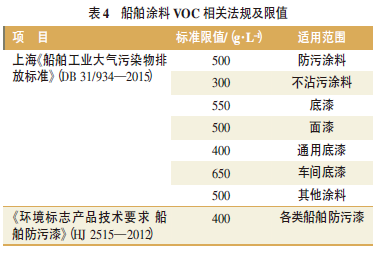

3.5.2 船舶制造涂料国内法规要求

国内船舶制造涂料 VOC 相关法规及限值见表 4所列。

3.5.3 减排可行性技术方案

在钢板预处理、车间底漆等生产工序,实施密闭式自动化喷涂,加装有机废气收集系统和处理装置,推广使用水性无机富锌车间底漆技术。在分段、整船涂装等生产阶段,大幅度提高船舶分段涂装率,提高涂料的固含量,推广使用高压无气喷涂、空气辅助无气喷涂等高涂着效率喷涂技术,分段涂装工序力争做到密闭作业,加装有机废气收集系统和处理装置。

4 结语

目前,国内新发布的 VOC 排放标准特点为:管控项目大幅增加,重点区域增设了特别排放限值,无组织排放受到极大重视。2016 年 7 月 8 日,工信部财政部发布了《重点行业挥发性有机物消减行动计划》,According to该计划制定的目标,到 2018 年工业行业 VOC 排放量比 2015 年消减 330 万 t 以上,低(无)VOC 的绿色涂料产品比例达到 60%以上。在涂料行业的主要任务是原料替代工程,在涂装领域实施生产过程封闭化、连续化、自动化技术改造,实施回收及综合治理工程,真正做到“源头控制,过程管理,末端治理”。

参考文献:

[1] Zhao Jianguo, Yang Lixian, Chen Xiaoshan, et al. Research on VOC Pollution Control Policy and Technology in the U.S. Paint Industry [J]. Coating Industry, 2012, 42 (2): 44-48.

[2] Qi Xiangzhao, Lu Wenhui, Niu Changrui. Research on VOC Pollution Control Policies and Regulations in the Paint Industry [J]. CHINA Paint, 2015, 30(2):9-13.

[3] Yang Yuande. Analysis of VOC Emission Reduction in Paint Industry [J]. CHINA Coatings, 2014, 29