As usual, we will no longer discuss what is the cross-cut method or what is the adhesion. The North and South Tide will take you directly to the topic, and sort out the problems of the cross-cut method that users often encounter in measuring adhesion:

1. Relevant standard basis for measuring adhesion by cross-hatch method

There are basically three standards for the cross-cut method of paint film at home and abroad:

GB/T 9286-1998 "Cross-cut test of paint and varnish film

ASTM D 3359-2002 "Determination of Adhesion by Tape Method"

ISO 2409-2007 "Paints and varnishes - Cross cut test"

The relevant instruments that meet the three cross-cut method standards can be viewed in the table below:

| ISO 2409 |

2. How to choose the cross-cut adhesion instrument

First of all, the cross-cut method is limited to less than 250 μm in the industry for measuring adhesion. In this environment, the cross-cut device can be selected as follows:

| 0~60μm | 1mm pitch | Hard substrate |

| 0~60μm | 2mm spacing | Soft substrate |

| 61~120μm | 2mm spacing | Hard or Soft Substrates |

| 121~250μm | 3mm spacing | Hard or Soft Substrates |

In this regard, the North and South Tide already has the option of what you see is what you get in the "Check Instrument" system, click to view

In addition, users can choose from the functional point of view. For example, some scribes usually use multiple blades (see Figure A). Repeat the test to improve the accuracy of the test. At the same time, the manufacturer represented by TQC in the Netherlands added a head rotation device (see picture B) when designing the instrument. This device can offset the uneven force on the left and right sides caused by manual operation and cause errors.

3. The operation steps of the cross-hatch method to determine the adhesion

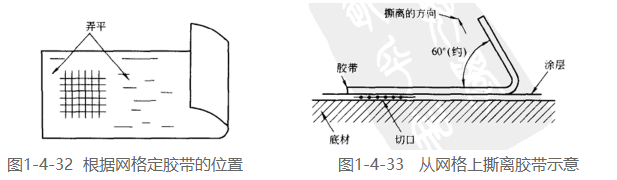

(1) Place the painted surface of the sample on a hard, flat surface. Hold the cutting knife so that the knife is perpendicular to the surface of the model, apply force evenly, and draw 6 parallel cutting lines in a steady manner. Then draw 6 parallel cutting lines perpendicular to the original cutting line at an angle of 90° to form a grid pattern. All cuts need to penetrate the surface of the substrate. (2) Use a soft-bristled brush to gently sweep backwards and forwards several times along each diagonal of the grid pattern.

(4) Apply tape on the sample plate of the hard substrate, remove the front section of the tape, then cut off the tape with a length of about 75mm, place its center point above the grid and flatten it, the length of the tape should exceed the grid by at least 20mm, and ensure that It is in full contact with the paint film.

(3) Within 5 minutes of sticking the tape, hold the suspended end of the tape, and at an angle of 60° as far as possible with the surface of the sample, tear off the tape smoothly within 0.5~1.0s. Then observe the peeling phenomenon of the paint film visually or with a magnifying glass agreed by both parties.

(4) Conduct tests on three different parts of the sample surface, and record the cross-cut test grade.

Detailed operation graphic display: https://www.nbchao.com/k/1840/

Detailed operation video demonstration: https://www.nbchao.com/k/1830/

Pay attention to details in detailed operation: https://www.nbchao.com/k/1259/

4. Identification of the results of cross-cut adhesion determination

The determination of cross-cut adhesion results is mainly carried out by visually calculating the state in the cross-cut. In this regard, the above-mentioned standards are clearly described. Regarding the result determination, the North-South Tide pays more attention to how the cross-cut device should be calibrated. Many users think that the cross-hatcher does not need to be calibrated, which deviates from the purpose of detection. For calibration, please refer to: https://www.nbchao.com/k/1259/ . The figure below shows the adhesion rating table for the result determination:

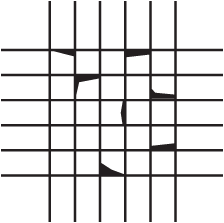

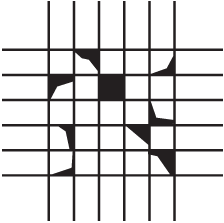

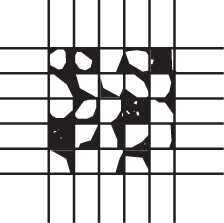

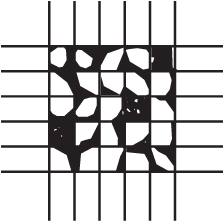

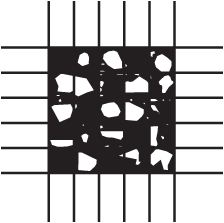

| Adhesion rating | Peeling degree | sample image |

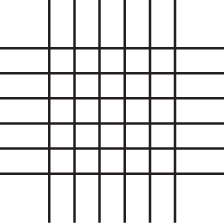

| 5B | 0% - no flaking |  |

| 4B | less than 5% |  |

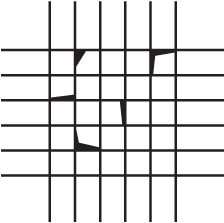

| 3B | 5%-15% |   |

| 2B | 15%-35% |   |

| 1B | 35%-65% |   |

| 0B | more than 65% |  |