There are two types of steel bar scanners for non-destructive testing of steel bar cover thickness: electromagnetic induction and radar. This article mainly introduces electromagnetic induction.

Detection principle

The rebar scanner is composed of two parts, the probe and the host, and the working principle of the probe part is electromagnetic pulse. There are two sets of coils installed inside the probe, one set is a magnetic field coil and the other set is an induction coil. The magnetic field coil generates a high-pulse primary electromagnetic field in the concrete to be inspected. If there is a metal object in the concrete, the object will induce a secondary electromagnetic field (located within the aforementioned first electromagnetic field). The pulse gap of the electromagnetic field generated by the magnetic field coil every time will cause the attenuation of the second electromagnetic field, so that the voltage of the induction coil will change. Therefore, according to the change of this voltage, the spacing of steel bars and the thickness of the cover in the concrete are calculated mathematically.

Detection method and application

1. Detective quick scan

The scanner moves perpendicular to the steel bar on the surface of the concrete structure, measures the position and depth of the steel bar and can mark it on the surface of the concrete structure. This method can quickly position and scan the steel bar in the structural member. In testing, this method can be used to prevent the drilling rig from drilling the steel bars.

2. Record fast scan

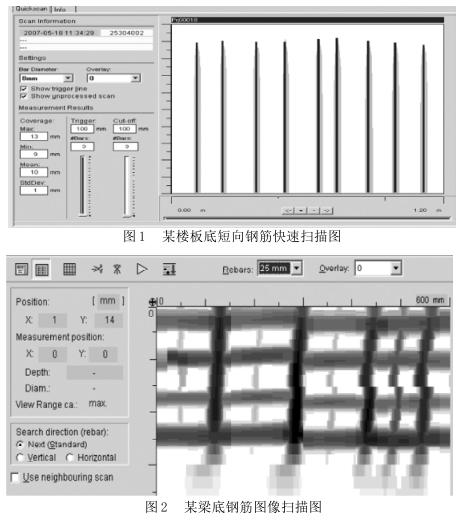

The scanner works in the same way as in Part 1, but when the scanner is moved over the surface of the concrete structure, the data obtained is recorded, after which the inspector can transfer the data to the host computer and download it to a computer for analysis , Archive (see Figure 1). This method is simple and convenient to operate, but other metal substances in the structural components such as pipelines will have a great impact on the test results, and it is easy to cause "missing reinforcement" or "multiple reinforcement". The layer is detected without considering its reinforcement condition.

3.3 Image scanning

Arrange the grid in the area to be tested, select the image scanning mode of the scanner and scan along the horizontal and vertical grids according to the prompts on the display screen. The data obtained during the scanning process can be transmitted to the host and computer for viewing and analysis, and the position of the reinforcement and the thickness of the protective layer can be determined with the surface of the concrete structure as a reference (see Figure 2). Image scanning can intuitively present the distribution of steel bars inside the concrete, and is less interfered by other metal substances, which is more conducive to the inspectors to make accurate judgments on the distribution of steel bars. The determination of the number of steel bars is more accurate than fast scanning, but image scanning The operation is complicated, especially in the scanning of the steel bar at the bottom of the beam, which is difficult to master.