1 Introduction

Since 2009, bright full-glazed products have gradually become the mainstream products in the domestic ceramic market, and the homogeneity has become more and more serious. At present, the surface gloss of full-glazed products or marble tiles sold in the market is generally about 90°. From the perspective of practical use in home life, it causes light pollution to a certain extent and interferes with people's vision. In the past two years, the emerging porcelain soft-gloss full-polished glazed tile adopts three-dimensional flexible mirror polishing technology, which makes the brick surface produce diffuse scattering and reduces the reflectivity of the polished surface of the brick, so as to achieve a soft light effect. The soft light effect of porcelain glazed fully polished tiles is between the strong light of bright fully polished glazed tiles and the weak light of matt tiles, and its gloss is generally between 30 and 60°, which is also in line with human vision. Comfort range. The polishing technology of large-scale wall and floor tiles is the key to the final quality of glazed polished products. The polishing process is relatively complicated, and there are many factors that affect the polishing quality.

In this paper, aiming at the three-dimensional flexible mirror polishing effect of porcelain soft-glazed full-polished tiles, the polishing production process of porcelain glazed tiles is studied, and the glazed tile product back grain, polishing abrasive tools, and polishing processes in the post-production process of the product are discussed. And the influence of polishing and waxing process on the polishing uniformity of porcelain soft-glazed three-dimensional flexible mirror, which provides practical reference for the research, production and application of three-dimensional flexible and soft (referred to as double soft) mirror polishing technology for porcelain glazed tiles in accordance with.

2 experiments

2.1 Experimental materials

⑴Ordinary antifouling wax, nano super clean wax, nano soft wax——produced by a professional ceramic chemical technology Co., Ltd. in Foshan.

⑵Black pen ink——Hero brand black ink produced by Shanghai Ink Factory.

⑶ Polishing Abrasives —— Manufactured by Foshan Jingmo Ceramic Materials Co., Ltd.

2.2 Experimental tests and instruments

⑴Soft mirror polishing process test——Use the new reciprocating swing polishing machine of Guangdong Keda Electromechanical Co., Ltd. to perform three-dimensional mirror polishing on porcelain glazed tiles.

(2) Gloss performance test——The gloss of the tile surface refers to the ability of the tile surface to reflect light. The WGG60-Y4 gloss meter produced by Keshijia Photoelectric Instrument Co., Ltd. is used to test the glossiness of the brick surface. The glossiness of the porcelain soft glaze full-throwing brick in this project is controlled at about 50°.

⑶Anti-fouling performance test——Use black pen ink to evenly smear on the polished and dewaxed brick surface, and then perform destructive treatment by stepping on it. After testing the ink on the brick surface for 24 hours, clean it with water and a rag. In order to compare the changes in the glaze effect of the product before and after the test.

⑷ Determination of Pollution Resistance: According to GB/T4100-2006 "Ceramic Tiles" Appendix G standard, GB/T3810.14-2006 Ceramic Tiles Test Method Part 14: Determination of Pollution Resistance.

2.3 Main polishing process

Porcelain glaze release semi-finished bricks → profiling elastic polishing → flexible polishing → applying nano antifouling wax water → edge grinding → pasting plastic film → packing.

3 Results and discussion

3.1 The effect of product back texture design on the uniformity of three-dimensional flexible mirror polishing of porcelain soft glaze glazed tiles

In the production process of soft mirror polishing of ceramic glazed tiles, it is often necessary to readjust the polishing parameter settings due to the difference in the back grain texture of the product, and the adjustment range is large, which affects the uniformity of soft mirror polishing to a certain extent. This is because different product back grain textures lead to different brick shapes of the products, so the polishing parameters need to be adjusted, which affects the polishing uniformity of the products.

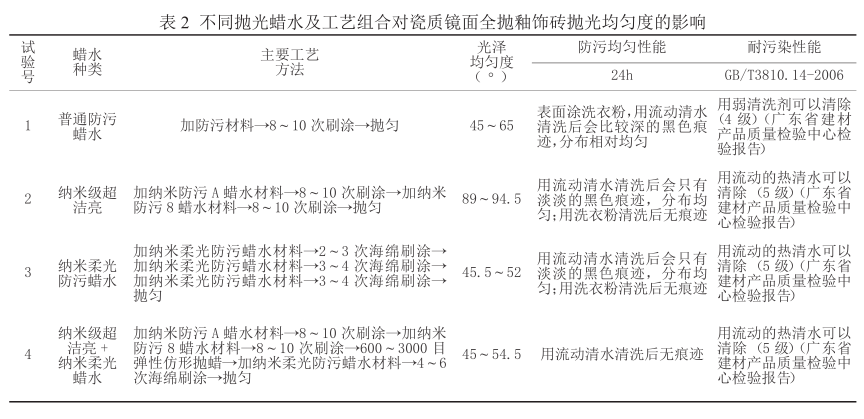

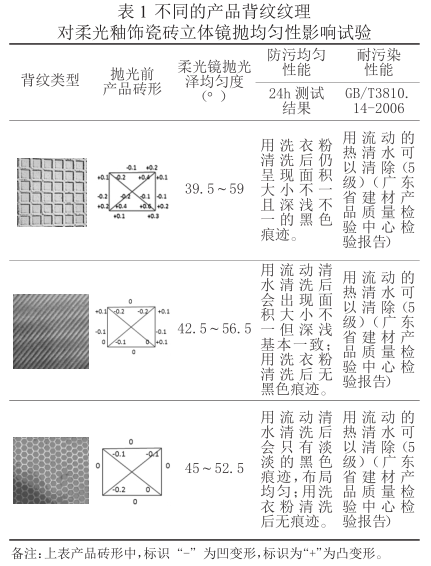

Brick shape is a process parameter that needs to be strictly controlled in the production process of glazed mirror polishing products, which directly affects the polishing and paving effects of products. In order to better explore the effect of product back grain texture design on product brick shape and soft mirror polishing uniformity, under the same process conditions (same press equipment, uniform glaze formula and process parameters, same kiln and kiln location) ), a series of on-line comparative production tests were carried out on products with different back grain textures (square grid, 45° diagonal stripes, regular hexagonal honeycomb grain) commonly used in actual production. As in Table 1.

It can be seen from Table 1 that the effect of the soft mirror polishing product with regular hexagonal honeycomb pattern is better than the other two back patterns, and it also shows that different product back patterns have an impact on the brick shape of the product and the polishing uniformity of the soft mirror. varying degrees of impact.

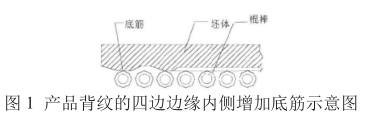

In order to make the glazed tile products achieve the uniform effect of the middle part and four sides of the polished surface, on the premise that the formula of the large-scale production body is stable, it is also possible to add a bottom rib on the inner side of the four sides of the back pattern of the product (as shown in Figure 1) to improve The flatness of the product. Some studies have shown [4] that the specially designed bottom mold for glazed tiles is to set a groove on the inner side of the four edges of the conventional bottom mold, so that a rib is added to the inner side of each edge of the corresponding brick body, and the center of gravity of the original brick edge is changed. The position moves the center of gravity of the brick edge outwards, which solves the problem that the glaze layer on the four sides is too thick and collapsed due to the deformation of the brick after the brick is softened and the glaze melts and flows to the four sides during the firing process.

3.2 The influence of the design of polishing abrasives on the polishing uniformity of the three-dimensional flexible mirror of porcelain soft-glazed glazed tiles

由于釉饰砖的釉层相对比较薄,一般情况下所抛削的釉层深度为 0.10~0.2mm。如采用抛光砖的“刚性”抛光方式,就容易在砖表面产生局部缺花、缺釉现象。因此在进行釉饰砖釉层镜面抛光时,其对抛光磨具要求是比较高,其关键技术在于磨具结构的设计上。

在现有陶瓷厂的瓷砖抛光流水生产工序中,常用的抛光磨块有菱苦土 SiC 磨具、金属结合剂金刚石磨具、树脂金刚石软磨片、海绵抛光擦以及树脂金刚石磨具等。According to不同瓷砖品类的抛光效果,选择不同种类的抛光磨具。抛光磨具中的磨料主要的用途为磨削抛光作用,应具备相当高的硬度,并且要在磨削抛光过程中能抵抗碎裂、保持切削刃的能力。金刚石就是抛光磨削很好的磨料,无论是天然金刚石,还是人造金刚石,都具有硬度高,耐磨性好,摩氏硬度高达 10,显微硬度为10000kg/mm 2 ,显微硬度比石英高 1000 倍,比刚玉高 150倍,可广泛用于切削、磨削、钻探。针对陶瓷釉饰砖全抛釉层厚度的特点,一般都会采用 T 型弹性树脂金刚石磨具进行釉饰砖面仿形抛光。树脂金刚石磨具具有一定的弹性和较高的结合性、导热性和强度,以及自锐性好、不易堵塞等特点,同时According to不同金刚石目数搭配可以粗抛、精细加工,具有良好的抛光性能。特别是纳米Si3N4 改性聚酰亚胺树脂型金刚石磨具。

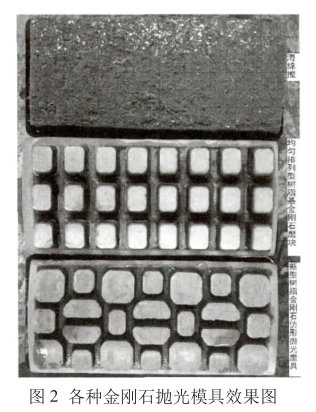

现有市场上的弹性树脂金刚石磨具一般分为:全弧型树脂金刚石磨具、小柱块排列均匀型树脂基金刚石磨块。全弧型树脂金刚石磨具能一定程度上解决砖面与磨具之间刮擦而产生的划痕 [9] 。但由于其全弧整面块状结构,仿形效果有限,容易使釉饰表面局部抛露底,因此常用于瓷质抛光砖产品抛光工序。目前行业内抛釉饰产品抛光阶段大都采用柱块排列均匀型树脂基金刚石磨具,采用排列规整的树脂金刚石磨具进行抛光,其工作面能够According to砖面形状自由调整方向,仿形抛光功能强,抛光时间较短,能提高砖面光洁度。由于这种金刚石磨块均匀排列整齐,抛光磨盘按一定的轨迹行走时,得到的柔光镜抛釉面容易产生有规律性的波浪纹,甚至无法消除,其镜抛抛光均匀度就难进而保证。

为了达到釉饰瓷砖柔光镜抛均匀效果,在上述两种弹性树脂金刚石抛光磨具的基础上,项目设计出新型树脂金刚石仿形抛光磨具(如图 2),其表面特点为:多行不同形状不同大小的磨粒成弧状非规则排列。同时将小磨块粒的边角设计为 45°圆弧状,以减少抛光过程中磨粒对水流通的阻力,保证抛光过程中每个角落水流的畅通性和均匀性,避免工件灼伤。在实际饰面砖抛光生产的过程中,上一排金刚石磨头抛光所留下的磨痕由下一排非规则排列的金刚石磨头磨抛掉,如此层层消磨淡化磨痕,使抛光后砖面的波浪纹变浅或甚没有波浪纹,从而提高釉饰抛釉砖的柔光镜抛均匀品质。

3.3 抛光工艺对瓷质柔光釉饰砖立体柔性镜抛均匀性影响

抛光工序是保证釉饰柔光镜抛砖表面粗糙度和光泽度均匀性的关键技术。在抛光过程中最为关键的设备部位是抛光磨头凸轮机构。常见的抛光磨头机构分为摆动式、圆柱滚动式、圆锥滚动式和行星端面式四种。本文采用广东科达机电股份有限公司的新型往复式摆动式抛光机作为项目釉饰瓷砖的镜面抛光设备,有实践表明:通过输送带将釉饰砖以一定速度的纵向运动,抛光机上面的曲柄滑块带动横梁摆动而使抛光磨头凸轮机构作往复的直线运动,以及正在砖面往复摆动抛光磨具的高速自动旋转运动复合成了三元运动,实现了柔光镜抛抛光均匀和改善漏抛。

抛光的目的就是釉饰抛釉砖表面获得均匀的光泽度和平整度。这就要求在抛光过程中,既要考虑釉饰砖釉层允许的抛削量,又要考虑抛光表面均匀度。因此除了研究抛光磨头机构的运行方式与曲柄摆动规律,还要对抛削速率、抛光磨具材质以及抛光磨具磨粒目数等抛光工艺参数进行摸索确定。在项目实验中,通过新型往复式摆动式抛光实际生产试验综合对比分析,采用弹性抛光工艺与柔抛工艺相结合的抛光工艺可以提高柔光釉饰砖镜抛抛光均匀度。这种组合抛光工艺即采用新型树脂金刚石仿形抛光磨具釉饰沿着釉饰砖面的形状进行仿形修整抛光,其磨具的磨粒目数由 150 目到3000目依此递增;然后再采用 4000~5000 目海绵金刚石抛光擦进行超精细抛光来淡化磨痕或波浪纹变浅。

3.4 The effect of polishing and waxing process on the polishing uniformity of the three-dimensional flexible mirror of porcelain soft-glazed glazed tiles

Porcelain polished tiles that have been laid and used generally have poor anti-pollution performance, and their surfaces are easily polluted, which affects their cleaning and aesthetic effects. This is because many small cracks and pores of different sizes are produced on the surface of porcelain polished tiles after polishing. Therefore, it is generally treated with nano-protective film technology on its polished surface to improve the antifouling performance of the tile surface. Porcelain mirror full-glazed tiles are similar to porcelain polished tiles, which need to go through a series of mirror polishing processes, so there are also some tiny pores or pores on the surface, although porcelain mirror full-glazed tiles The surface of the tile is a layer of transparent glaze similar to glass, which is denser than the surface of porcelain polished tiles. Therefore, this project discusses the effect of polishing wax water on porcelain soft light mirror full polished glazed tiles by conducting different polishing wax water selections and series of process comparison tests (as shown in Table 2) on porcelain soft light mirror full polished glazed tiles. The influence of brick polishing uniformity.

From the experimental results in Table 2, it can be seen that the combination of nano-scale super-clean and nano-soft wax water and its technology for antifouling treatment of porcelain mirror full-glazed tiles is better than other schemes, and the surface gloss of the tiles is 45~ 55°, there is no trace after washing with flowing water, the anti-fouling performance reaches level 5, and its anti-fouling and anti-fouling uniformity performance is very good.

4 Conclusion

⑴Through experimental comparison and analysis, it is proved that the glazed polished glazed tile products produced by regular hexagonal back grain use the new resin diamond profiling polishing abrasive tool for composite ternary motion polishing combined with elastic polishing process and soft polishing process, and nano-scale The waxing process combined with ultra-clean brightening and nano soft light antifouling agent can effectively improve the polishing uniformity of the three-dimensional double soft mirror of porcelain glazed tiles.

⑵The surface gloss of the porcelain soft-light glazed full-polished glazed ceramic tile produced by using the three-dimensional flexible soft-light mirror polishing technology achieves a soft-light effect, and its gloss is about 50°. This soft-light effect is in line with the range of visual comfort for human living.