1 Introduction

Since 2009, bright full-polished glaze products have been loved by consumers because of their smooth and bright surface, well-proportioned color, and rich and colorful patterns. They have become popular all the way and become the mainstream of the domestic ceramic market.

Polished glazed tiles are similar to polished tiles. After a series of polishing processes, there are also some tiny pores or pores on the surface. It is denser, but the existence of gas phase in the brick body is inevitable, and the existence of these gas phases is also the main reason for the dirt absorption of glazed tiles.

The antifouling performance of glazed tiles is related to the water absorption rate of the product, and also related to the content of holes and closed pores in the glaze layer or on the brick surface [5]. Therefore, to solve or improve the antifouling performance of glazed tiles, it is necessary to reduce the amount of air bubbles remaining in the surface transparent glaze as much as possible. Due to resource and cost constraints, the body of the existing polished glazed tiles is generally used. Therefore, in order to reduce the residual air bubbles in the glaze layer, the first thing to do is to start with the glaze. At present, the full-polished transparent glaze of polished glazed tiles is mainly the whole raw material type or the raw material with frit type. There are more volatiles in the glaze formula, and the glaze itself is burned. It is easy to generate a large amount of gas and cannot be removed in time, resulting in a large number of bubbles of different sizes in the glaze layer.

Calcite, barium carbonate, clay, kaolin, etc. are the commonly used glaze raw materials in the transparent glaze formula of polished glazed tiles. Calcite decomposes at a high temperature of 860 ~ 970 ℃ to generate CaO and CO 2 gases, which can reduce the glaze loss. The number of bubbles in the layer; talc starts to dehydrate when heated to about 600°C, and the structural water is completely discharged in the range of 880-970°C; these carbonates will decompose and produce gas when fired at high temperature, resulting in pinholes and bubbles (closed bubbles) on the glaze surface. or open bubbles), which is not conducive to the antifouling performance of the glazed tile glaze; clay will volatilize water or other organic impurities under high temperature conditions, and will be converted into mullite when the temperature is 1050 ℃, and mullite machinery High strength, can improve the hardness and transparency of the glaze. It can be seen that calcining, a common method of raw material treatment in the ceramic industry, can volatilize the moisture and organic matter of the raw material and decompose the carbonate during the calcining process, so as to improve the purity of the material, produce crystal transformation, and solid phase reaction. Change the technical performance of the material, and then obtain better performance of the raw material for glaze.

Based on the existing conventional full-glaze technology, this project changes the characteristics of the full-glaze raw materials by using the calcination method, and at the same time adjusts the corresponding glaze formula and formulates a reasonable kiln firing system to comprehensively reduce the transparency of the glazed tiles. The size and number of residual air bubbles in the glaze layer, discuss the influence of the full glaze before and after calcination on the antifouling performance of the glazed glazed tile after polishing, and improve the high stain resistance quality and product quality of glazed tiles from the characteristics of glaze raw materials The production stability and controllability provide a reference for comprehensively improving the antifouling performance of glazed glazed tiles.

2 experiments

2.1 Sample preparation

The experimental raw materials are industrially pure glaze raw materials. After weighing a certain amount of raw materials according to the current production and use of the large-scale production of raw material transparent glaze with good antifouling performance (No.: QSL-901), add 0.2% by mass CMC, 0.3% sodium tripolyphosphate and 45% water were put into a ball mill jar for ball milling, and a fast ball mill was used for continuous ball milling, and every 100 g of dry material was ball milled for 10 minutes to obtain a glaze slurry. When measuring the ball milling fineness of the glaze slurry, 325 mesh sieve residue < 0.1%, release the slurry, dry it in a microwave oven until the moisture is 7 to 8%, then use a 20 mesh screen to granulate, and use an experimental press to press the long bricks. Place a gradient electric furnace for high-temperature calcination, and break the calcined long bricks into powder (code: DSL-909); according to the experimental formula, add an appropriate amount of air knife soil, calcined kaolin and oxidized Aluminum and other raw materials are ball-milled into transparent glaze slurry, which is poured on the large production body of cosmetic soil, and the transparent glaze slurry is scraped with a glaze scraper with a thickness of 0.5 mm. The instrument temperature is 1175 °C, the firing time is 68 min), and the fired bricks are polished to obtain samples.

2.2 Main experimental equipment

Use the GS6202 electronic scale of Japan Shinko Electronics Co., Ltd. to carry out the batching of all raw material glaze powder;

Use the YDK-500B experimental press of Guangdong Foshan Kangsida Hydraulic Machinery Co., Ltd. to press the whole raw material glaze powder into long bricks;

The SXT-4-13-4 gradient electric furnace of Xiangtan Instrument Equipment Co., Ltd. is used for high-temperature calcination of all-raw glaze powder long bricks;

The melting range of the fully polished transparent glaze was tested by a computer temperature-controlled high-temperature imager from Xiangtan Instrument Equipment Co., Ltd.;

Use the new reciprocating swing polishing machine of Guangdong Keda Electromechanical Co., Ltd. for three-dimensional mirror polishing;

Use the WGG60-Y4 gloss meter produced by Keshijia Photoelectric Instrument Co., Ltd. to test the gloss of the mirror polished brick surface;

Use the SO 2 portable electronic magnifying glass produced by Shenzhen Haoteer Electronic Technology Co., Ltd. to characterize the glazed surface of the sample, and the magnification factor is 400 ×.

2.3 Experimental test method

Antifouling performance test: Use black pen ink to evenly smear on the polished and dewaxed brick surface, and then destructively treat it by stepping on it. After the ink test on the brick surface for 24 hours, clean it with water and a rag, so as to compare before and after the test Changes in product glaze effect; Pollution resistance determination: According to GB/T4100-2015 "Ceramic Tiles" Appendix G standard, GB/T3810.14 Ceramic tile test method part 14: Determination method of pollution resistance.

3 Results and discussion

3.1 Selection of glaze calcination temperature

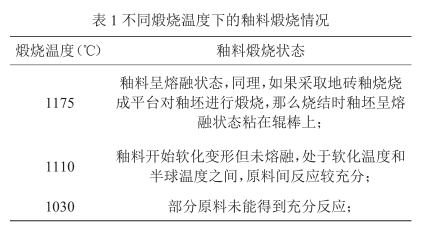

The calcination temperature is determined according to the calcination range of the mass-produced all-raw material transparent glaze formula (No. QSL-901) with good antifouling performance and the calcination requirements of the glaze raw materials. In order not to build and add new equipment or production lines when the raw material glaze is calcined in large quantities in the later stage, so as to make the best use of everything, a more suitable calcining platform is selected in combination with the company's existing firing process platform. There are three types of existing wall and floor tile firing process platforms: floor tile glaze firing, tile plain firing and porcelain tile glaze firing. The maximum temperature of the flake glaze firing kiln is 1030°C. The long glazed bricks pressed by the experimental press were calcined in a gradient electric furnace at high temperature, and the calcining effect is shown in Table 1.

It can be seen from Table 1 that calcining the glaze at 1110 °C can improve the purity of the material, produce crystal transformation and solid phase reaction, and change the process performance of the material. For example, calcite (decomposes at 860-970°C), talc (begins to dehydrate around 600°C, and completely discharges structural water at 880-970°C), kaolin (converts to mullite at 1050°C). At the same time, the glaze material will not be in a molten state due to the high calcining temperature, which will cause the sintered glaze body to stick to the roller rod during the batch calcining process. Therefore, we choose the plain-fired firing process platform of porcelain slices to calcine the whole raw material glaze.

3.2 Effect of high temperature holding time on the stain resistance of glazed tiles

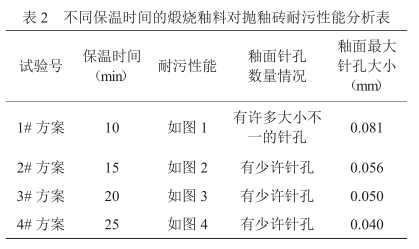

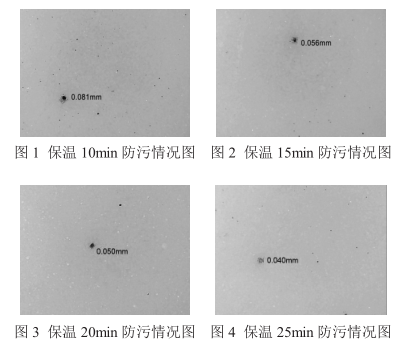

In order to fully respond to the glaze calcination process, at a calcination temperature of 1110°C, the effect of glaze calcination high temperature holding time on the stain resistance of glazed tiles was tested. The long glazed bricks were pressed by an experimental press, and fired at a high temperature in a gradient electric furnace to investigate the antifouling effect of the calcined glaze on the glazed surface of the polished glazed bricks at different holding times (see Table 2 and Figures 1 to 4).

从表 2 和图 1 ~ 4 可以看出,不管是从数量上还是针孔直径大小,在 1110℃的温度下,煅烧保温时间 15 min 的釉面效果明显要好于采用煅烧保温时间 10 min 的釉面;当煅烧保温时间逐渐加大到 20 min 和 25 min 时,其针孔数量没有明显的变化,只是针孔大小稍微变小一些,同时煅烧所需的单位能耗也会随之增加。因此,综合分析所得,在 1110℃的温度下,煅烧保温时间 15 min 所得的煅烧釉料可以有效地改善抛釉砖抛光釉面防污效果。

3.3 煅烧釉料掺入量对耐污性能的影响

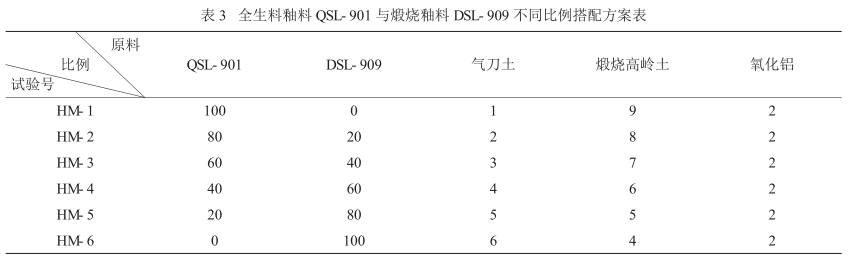

为了系统地试验煅烧釉料对抛釉砖耐污性能的影响,According to釉料配方温度接近原则,将制备的煅烧釉(DSL-909)料与目前公司防污性能很好的大生产全生料透明釉(QSL-901)按不同比例搭配得到不同透明釉浆料,以研究不同掺入量的煅烧釉料对抛釉砖防污性能的影响(如表 3)。

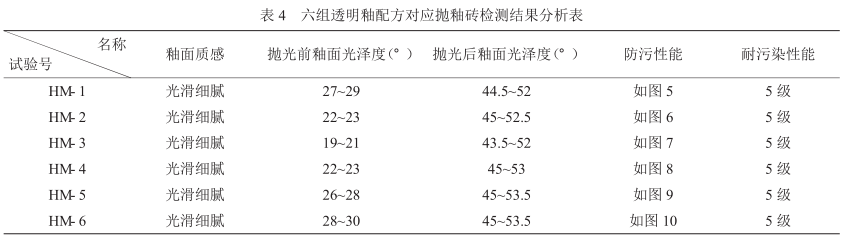

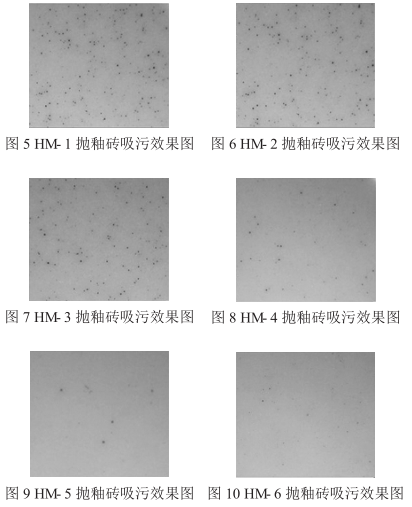

所制得的样品抛光前后检测数据如表 4 和图 5 ~ 10所示。(备注:以上为试验样板经抛光后未打蜡进行测试防污状况图。MRK 放大镜拍摄:400 倍图片。)

由表 4 和图 5 ~ 10 可知:随着配方中煅烧釉料比例的增加,所对应的抛釉砖防污明显程度顺序为:HM-1>HM-2>HM-3>HM-4>HM-5>HM-6,HM-6 透明釉所制成的抛釉砖的釉面防污性能更好,说明煅烧料可以有效地改善抛釉砖产品的防污性能,同时达到国标 5 级的耐污性能。

在釉料配方中大量使用煅烧料,相当于延长了釉料的烧成时间,有利于产品的快速烧成。煅烧釉料与化学成分相近的全生料釉相比,其活性高,容易产生玻璃相,从而填充釉料颗粒之间的空隙,保证产品釉面抛光后的颗粒与颗粒之间的空隙不被裸露,有利于提高抛釉砖釉面的防污性能,同时还有利于提高坯釉结合性能。

At the same time, considering that the calcined glaze is barren, special attention should be paid to the performance of the glaze slurry when using it, especially when using the glaze production process. 100% calcined material is directly used as glaze, and a large amount of auxiliary materials need to be added to adjust the suspension performance of the glaze slurry to avoid easy precipitation. Considering the operational controllability of the production glaze process, the project's transparent glaze formula option 5 (namely HM-5 formula) is more suitable.

3.4 Research on melting range of calcined transparent glaze

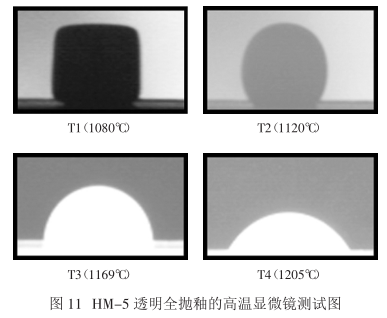

In order to effectively formulate the firing system of the project product, a computerized temperature-controlled high-temperature imager was used to study and analyze the melting range of the determined transparent full-glaze HM-5, as shown in Figure 11.

It can be seen from Figure 11 that the initial melting temperature of HM-5 transparent glaze is relatively high. At about 1080°C, the glaze material begins to soften, and most of the gas in the glaze has been removed, which is beneficial to avoiding the glaze surface remaining due to gas escape. Lower pits or pinholes; at 1169 °C, the glaze column melted to a height of 3 grids, indicating that the high-temperature fluidity of the glaze melt is more suitable, which is conducive to eliminating pits, pinholes and waves on the surface of the glaze melt. The melting temperature of this glaze is 1169°C, which is basically in line with the firing process of the existing kiln for the production of full glaze products (the maximum temperature of the instrument is 1175°C). As the firing temperature increases, the gas generated during the sintering of the fired body and the melting of the glaze is discharged in the transparent glaze layer, thereby reducing the content of residual air bubbles in the glazed layer.

4 Conclusion

By using the calcination method to change the characteristics of the raw material-type full-glaze glaze raw materials, the glaze formula of the raw material and the calcined material type has been successfully innovatively developed, which can effectively reduce the size and number of residual air bubbles in the transparent glaze layer of polished glazed tiles, and improve the glaze. The main conclusions obtained from the antifouling performance of brick glaze are as follows:

(1) Use calcining to change the technical performance of the glaze, calcining the glaze powder at a temperature of 1110 ℃, as the high temperature holding time continues to increase, the size and number of pinholes on the polished glazed surface of the polished glazed tiles made by it gradually decrease; When the holding time reaches 15 minutes, the number of pinholes in the glaze does not change significantly, and the size of the pinholes becomes relatively slightly smaller;

(2) Due to the high activity of the calcined glaze, it is easy to produce a liquid phase. A large amount of calcined material is used in the glaze formula, which is easy to fill the gaps between the glaze particles and ensure the contact between the particles after the glaze surface of the product is polished. The voids are not exposed, which is beneficial to improve the antifouling performance of the glazed surface of the polished glazed tile, and is also beneficial to improve the bonding performance of the base glaze.

(3) Integrating the controllability of the glazed tile production process, the HM-5 transparent glaze formula obtained in the project basically meets the firing process requirements of the existing large-scale production kilns.