In the past 20 years, CHINA's economic and social development has achieved world-renowned achievements, but this kind of development is more of a deformed development achieved by excessively plundering natural resources and sacrificing the environment. This unsustainable development is caused by The environmental problems caused by it are attracting more and more attention. Since July 2015, decoration materials such as solvent-based coatings and solvent-based adhesives have been completely banned in Shenzhen, and Beijing has also issued DB111202-2015 "Emission Standards for Air Pollutants in Wooden Furniture Manufacturing Industry". The water-based and safe coating process provides strong support and guarantee.

Water-based and ultraviolet (UV) coatings are relatively environmentally friendly compared to solvent-based coatings. However, there is a big gap between the performance and appearance of water-based coatings and solvent-based coatings, and the drying time of water-based coatings is long, which reduces the coating efficiency. UV coatings have the problems of curing shrinkage and yellowing, and the reactive diluents used in them are more harmful to human health. Compared with UV coatings and water-based coatings, the drying time of UV-cured water-based coatings is greatly shortened, and the problems of yellowing and volume shrinkage are eliminated. It is environmentally friendly and non-toxic, and is a type of coating with great application prospects.

In this study, a high-gloss UV-curable water-based white topcoat was prepared. This topcoat has the characteristics of high gloss, smooth hand feeling, and high fullness. Used in water-based systems, it can also be used in all-water-based UV systems to achieve a variety of matching designs in terms of performance and cost. It is the first choice for coating high-end white furniture series.

1 Experimental part

1.1 Main raw materials

Water-based UV resin: UCECOAT 7856 (solid content 45%), UCECOAT 7200 (solid content 65%), American Cytec Industries; Urosin 4695 (solid content 40%): Wanhua Chemical; WB2812 (solid content 35%): South Korea Meiyuan Commercial Co., Ltd.; Hexafunctional reactive monomer: dipentaerythritol hexaacrylate (DPHA), industrial grade, Jiangsu Sanmu Group Co., Ltd. Additives: Tego 822 (defoamer), Tego 830 (defoamer), Tego 752W (dispersant), Tego 245 (wetting agent), Tego4100 (wetting and leveling agent), Evonik Industries AG; BYK 2012 (dispersant), BYK 028 (defoamer), BYK 346 (wetting and leveling agent), German BYK chemical company; Hemings Deqian 1760 (foam inhibitor), ACRYSOL TM RM-2020NPR (thickener ), Dow Chemical Company; Ejuan FKA 3570 (leveling agent), Efka Chemical Company. Initiators: Irgacure 500, Irgacure 819, BASF Chemical Company. Pigment: rutile titanium dioxide (R-902), DuPont, USA. Anti-sedimentation agent gas phase SiO 2 , solvent: propylene glycol methyl ether acetate (PMA), pH regulator: N, N-dimethylethanolamine (DMEA), etc. are commercially available.

1.2 Main instruments and equipment

High-speed dispersing machine: Laizhou Guanxing Machinery Co., Ltd.; ultraviolet dryer (gallium lamp): Wujiang Zhisheng Machinery Factory; ultraviolet dryer (mercury lamp): Fushun Yicheng Woodworking Machinery Manufacturing Co., Ltd.; tunnel microwave infrared dryer: Guangzhou Kewei Microwave Equipment Co., Ltd.; Four-band UV Energy Meter, Pencil Hardness Tester and Barometer: Guangzhou Domestic Laboratory Instruments Co., Ltd.; Gloss Meter: Quanzhou Keshijia Photoelectric Instrument Co., Ltd.; Iwata Cup NK-2: Dongguan Wanjiang Weida Instrument.

1.3 Sample preparation and performance testing

The base material of the model is 30 cm×40 cm black walnut veneered medium density fiberboard, fully sprayed, according to the sealing primer 60~80 g/m 2 , primer 100~120 g/m 2 , top coat 80~120 g/m 2 g/m 2 standard for construction [3]. Spray the sealing primer once on the model, and apply the water-based UV white base twice, and polish it with 600-grit sandpaper for later use. The pre-drying of the water-based UV white topcoat is carried out by 3 processes. Process 1: After leveling at room temperature for 10 minutes, bake at 50 ℃ for 15 minutes; Process 2: Pre-dry at room temperature overnight; Process 3: After spraying, use crawler infrared microwave drying for 40 s. After pre-drying, use UV curing to dry, gallium lamp and high-pressure mercury lamp to cure once, curing energy UVA-870 mJ/cm 2 , UVB-731 mJ/cm 2 , UVC-221 mJ/cm 2 , UVV-947 mJ /cm 2 .

The basis for the determination of paint film properties: paint film hardness GB/T 6739-2006, determined by pencil method; paint film water resistance GB/T 1733-1993, determined by water immersion method; paint film adhesion GB/T 9286-1998, cross-cut test method Determination; paint film high-low temperature resistance GB/T 4893.7 — 1985, test of furniture surface paint film resistance to cold and heat temperature difference; paint film gloss using a gloss meter (60°), take the average value measured in 5 different areas as the paint The gloss of the film; the paint film is resistant to ethanol, take 95% industrial ethanol dropwise on the sample plate, the coating area is about 2 cm×3 cm, and observe whether there is discoloration, foaming or dissolution after 2 hours. No obvious change in the paint film is passed.

1.4 Preparation of water-based UV bright white topcoat

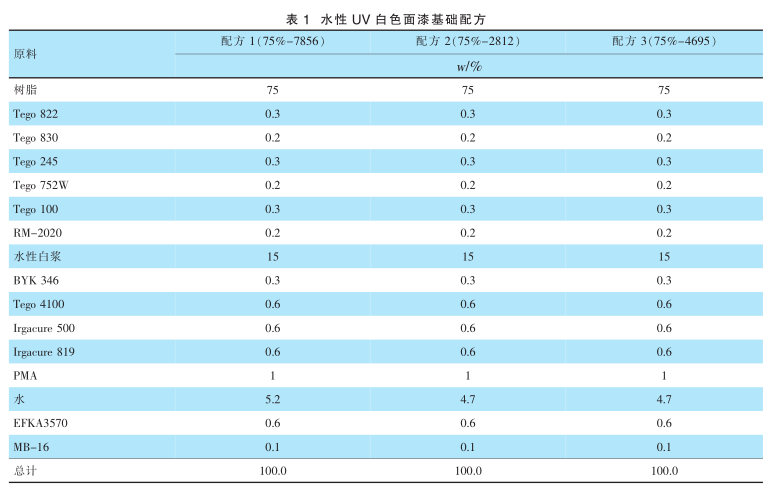

1.4.1 Selection experiment of high-gloss water-based UV resin Several water-based UV resins suitable for the preparation of high-gloss paints were selected, including UCECOAT 7856 (solid content 45%) from Cytec, Urosin 4695 (solid content) from Wanhua Chemical Co., Ltd. Content 40%), Miramer WB2812 (solid content 35%) of Korea Miwon Trading Co., Ltd., the basic formula is shown in Table 1 and Table 2. The photoinitiator in the formula is Irgacure 500 and the deep layer initiator Irgacure 819 to achieve uniform curing effect on the surface layer and deep layer; in order to achieve excellent surface effect, effective substrate wetting agent Tego 245, wetting and leveling agent Tego4100 and fluorine Carbon modified polyacrylic acid leveling agent EFKA 3570.

Apply the prepared water-based UV white topcoat evenly on the water-based UV white background sample by spraying, and control the construction viscosity at 15-25 s (coat 4-cup). The sprayed samples are pre-dried by process 1. After the pre-drying is completed, the template is passed through a gallium lamp and a mercury lamp in turn to complete deep curing and surface curing, and then a water-based UV template is obtained. The performance test was performed after the prepared sample was maintained for 7 days according to the test requirements.

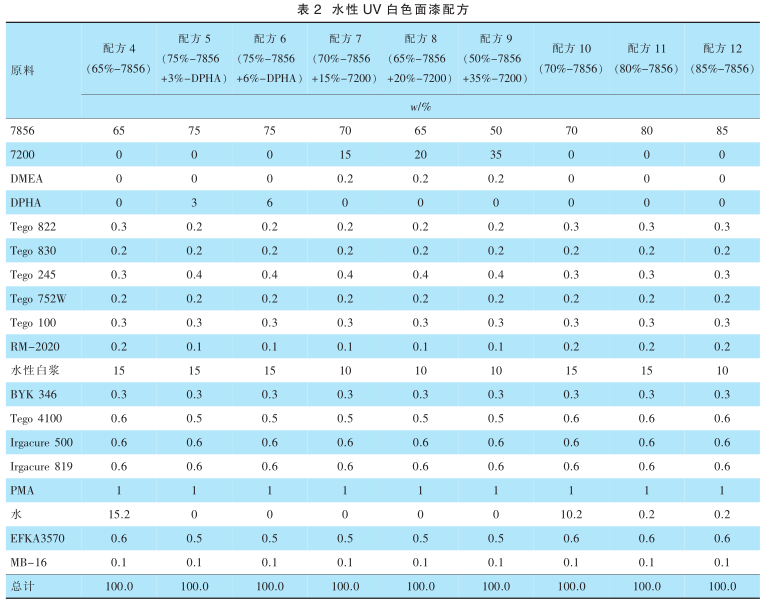

1.4.2 Optimal modification of water-based UV white topcoat

In order to obtain excellent surface effect and good paint film performance, the test adjusted the content of resin components in the formula for UCECOAT 7856 water-based UV resin, and designed the use of six-functional monomer DPHA or high-hardness resin UCECOAT 7200 for water-based UV The method of blending and modifying the white topcoat is, on the one hand, to obtain a better surface effect, and on the other hand, to further improve the performance of the paint film. The experimental basic formula is shown in Table 2.

1.5 Drying process and adhesion test of water-based UV white topcoat

In order to examine the process applicability of the prepared water-based UV white topcoat, the experiment used UCECOAT 7856 as the resin base to prepare the formula 4 coating, and used 3 different drying methods for pre-drying and UV curing drying. At the same time, formula 4 paint was sprayed on the UV white primer board, water-based one-component white primer board, and water-based two-component white primer board respectively, and then pre-dried and UV-cured. Adhesion between paints.

2.1 水性 UV 白色面漆性能的影响因素

2.1.1 水性 UV 树脂性能

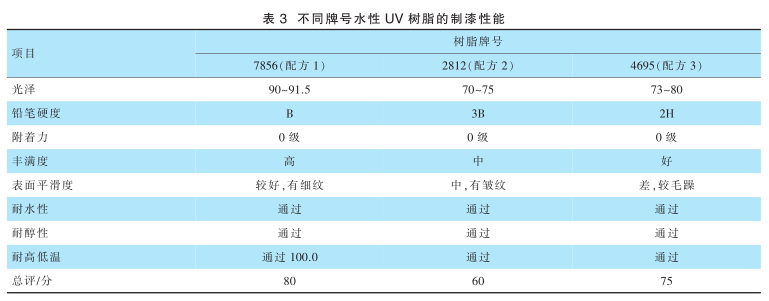

取不同品牌牌号的树脂制备水性 UV 白色面漆,测试其基本性能,如表 3 所示。 其中漆膜丰满度、表面平滑度采用目视观察的方法进行比较。 为了更好地评估各个样板的性能和整体效果, 对样板的综合性能进行了定性评分,即总评量化评判。

从表 3 可以看到,采用 4695 制备的水性 UV 白色面漆具有硬度高,耐水、耐醇性能好的特点,这是由于Urosin 4695 是一款指触干光固化树脂,其低聚物树脂组分的相对分子质量较大, 经过交联固化后得到的涂膜硬度较高,但是流平性能下降,造成漆膜表面性能较差,光泽不够高。增加助溶剂的用量可能有助于表面性能的提升。 UCECOAT 7856水性 UV 树脂可制备综合性能较好的高光泽白色面漆, 涂膜具有良好的耐醇和耐水性能,丰满度高,光泽均匀和表面平滑度较好的特点。 UCECOAT 7856 是一款非指触干光固化树脂,较低的相对分子质量使得其具有很好的流平性能, 不需要外加成膜助剂即可得到具有镜面效果的漆膜。 但是不足之处在于硬度较低,表面效果还可以进一步提高。为了解决这一问题,进行了配方优化。

2.1.2 树脂含量的影响

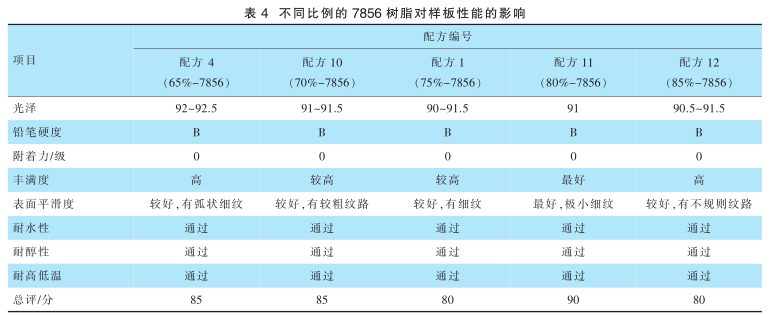

为了获得很好的的综合性能, 实验选取了不同的UCECOAT 7856 树脂组分含量制备了一系列水性 UV白色面漆,通过性能对比,以确定树脂成分在配方中的很好的比例。其中,配方 4 、 10 、 1 、 11 、 12 中 7856 比例分别为 65% 、 70% 、 75% 、 80% 、 85% ,性能测试结果见表 4 。

由表 4 可以看出, 树脂组分的变化对漆膜的理化性能没有明显的改善作用, 而对漆膜的表面性能具有一定的影响。各个配方都具有高光泽 (≥90°) 、高丰满度和较好的表面平滑度。 其中,当树脂含量为 65% 时 ( 配方 1) 漆膜具有很高的高光泽,为 92~ 92.5° ;当树脂组分为 80% 时 ( 配方 11) 漆膜综合性能很好的,表现为光泽高度均匀,丰满度最高,具有很好的油润感,同时表面平滑度更好,呈现高清晰度的镜面效果,单独不足之处在于硬度偏低。

2.1.3 混拼改性的影响

为了进一步提高漆膜的性能, 试验设计了 2 种方案提高水性 UV 白色面漆的硬度。 方案 1 为混拼少量六官能团单体 DPHA 的方法, 如表 2 中配方 1 、 5 、 6 所示,混拼单体比例分别为 0% 、 3% 、 6% 。 方案 2 为混拼增硬树脂 UCECOAT 7200 , 如表2 中的配方 7 、 8 、 9 所示,混拼比例分别为 15% 、 20% 、 35% 。通过比较配方 1 、5 、 6 , 可以得到 DPHA 对水性 UV 配方的改善效果;通过比较配方 7 和 10 、配方 8 和 4 、可以得到 7200 树脂对配方的改性作用, 通过比较配方 7 、 8 、 9 , 可以得到7200 比例的增加对水性 UV 白色面漆的性能影响。 各配方性能对比见表 5 。

对比表 5 中配方 1 、 5 、 6 发现, 添加 3% 的 DPHA即可显著提高水性 UV 白色面漆的硬度。 这是由于六官能团单体的引入能提高漆膜的交联密度, 使得水性UV 白色面漆的硬度提高。 但是单体的加入影响了漆膜的表面效果,当 DPHA 的添加量增加到 6% 时,漆膜硬度并没有提高,而表面效果则进一步降低,这可能是由于 DPHA 单体直接加入 7856 乳液中,单纯的机械搅拌很难实现均匀的乳化, 使得预干燥以后, DPHA 和7856 中的低聚物没有实现分子水平的均匀共混,最终引起漆膜在微观上的变形,使得表面平滑度下降。对比配 方 7 ( 70%-7856+15%-7200 ) 和 配 方 10 ( 70%-7856 ), 发现加入 15% 的 7200 可以将漆膜的硬度从 B提高到 H ,光泽也提高约 0.5° ,但表面平滑度未改善。对比配方 8 ( 65%-7856+20%-7200 )和配方 4 ( 65%-7856 ),发现加入 20% 的 7200 可以将漆膜硬度从 B 提高到 2H ,光泽均匀并且提高了 0.5° ,表面效果也与混拼之前相当。 对比配方 7 、 8 、 9 ,发现随着 7200 含量的增加,漆膜的硬度随之提高,但增加到 35% 时,虽然漆膜硬度增加到了 3H ,但漆膜丰满度降低,板面光泽降低并且不够均匀, 加入 20% 时漆膜获得了很好的的总体性能。

2.2 水性 UV 白色面漆的干燥工艺

水性 UV 涂料的干燥可以分为预干燥和固化干燥2 个过程。 对于水性 UV 乳液体系而言,其预干燥过程又可以分为 3 个阶段: 第 1 阶段水分直接从空气 - 水界面挥发,挥发速度非常快;第 2 阶段乳胶粒子开始融合聚集,水分从粒子间隙中挥发,挥发速度变慢,第3 阶段随着独立乳胶粒子的逐渐消失, 水性低聚物分子链相互扩散, 水分从低聚物分子内部迁移到表面,挥发速度非常缓慢。 涂膜最终含水量取决于低聚物分子和最终交联固化得到的聚合物分子结构 [5] 。 试验取配方 1 、 2 、 3 制备得到的 3 种水性 UV 树脂基涂料,采用 3 种不同的干燥方式进行预干燥, 以考查水性 UV白色面漆体系的工艺适用性和表面效果。 结果发现,通过 3 种干燥方式都可以得到外观良好,理化性能相当的漆膜,无起泡、橘皮等表面缺陷。 其中,通过自然干燥方法得到的漆膜表面平滑度很好的,这是由于相对红外微波干燥和鼓风干燥的方式,水分的自然晾干降低了水分挥发速度, 尤其是在预干燥的第 2 、 第 3 阶段,微量水分在乳液融合聚结成膜过程中具有增塑作用,使得漆膜微观流平性更好。 但是自然干燥所需时间较长,不太适用于流水作业的车间,因此在生产对外观要求很高的产品时可考虑选择自然干燥的方式,不仅表面效果很好的,还可降低能耗。 微波红外干燥是有效的干燥工艺,大大缩短了干燥时间,但漆膜表面效果有所降低。

2.3 水性 UV 白色面漆与不同体系的搭配

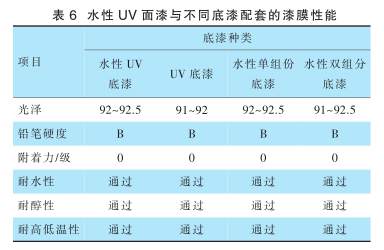

为了考查实验制备的水性 UV 面漆的工艺适用性,实验取配方 4 ( 65%-7856 )白色面漆,分别与 UV 底漆、水性 UV 底漆、水性单组份底漆、水性双组分底漆配套制板,测试层间附着力等漆用性能,结果见表 6 。

从表 6 中发现, 以配方 4 制备的水性 UV 白色面漆与 UV 底漆、水性单组份底漆、水性双组分白底之间具有很好的适用性, 不同的底漆对面漆的性能没有明显的影响, 其中面漆的硬度是制约配套体系漆膜硬度的关键因素。

3 结语

Through formula experiments, (1) UCECOAT 7856, a suitable water-based UV resin, was optimized to prepare a high-gloss water-based UV white finish paint. By optimizing the proportion of each component of the resin in the formulation, mixing DPHA monomer or adding high-hardness resin, the surface effect of the paint film is further improved, and the hardness of the topcoat is increased. The experimental results show that when the proportion of the resin component in the formula is 80%, the prepared water-based UV white topcoat has a better appearance; mixing a small amount of DPHA monomer can improve the hardness of the topcoat, but it will damage the surface properties ; Mixing high-hard resin UCE鄄COAT 7200 can improve the hardness of the topcoat, and has little effect on the surface properties. Only when the addition amount is large, the impact of UCECOAT 7200 on the surface properties is reflected. (2) The experiment examined different drying methods and the applicability of water-based UV white topcoat with water-based system and UV system. The results show that the coating film obtained after natural drying and curing has a good appearance, and microwave infrared drying can realize industrial Assembly line production. (3) The water-based UV white topcoat prepared in the experiment can be used in conjunction with UV, water-based one-component, water-based two-component, and water-based UV primers. It has strong adaptability and provides an environmentally friendly, Aesthetically pleasing, high-performance solutions.