In the past, the use of Air Compressors was basically refueling Air Compressors, but with the development of technology, there are disadvantages in the use of oil Air Compressors, and the country advocates environmental protection construction, etc., which has promoted the production of oil-free Air Compressors. And on the basis of oil-fueled Air Compressor technology, it realizes an oil-free design, which is more environmentally friendly and reduces some impacts caused by oil molecules. Let's take a look at some current situations that may be caused by oily Air Compressors through four phenomena.

Has this happened to your company's equipment?

1. Is the air pipe dirty?

Once mixed with bacteria and other substances, it will also cause hygiene problems.

Please check the inside of the air piping. The dirt inside the pipes exceeded expectations.

In the "gas"-like dirt made of rust, oil, moisture, etc., it can be seen that various bacteria are mixed.

2. Is there any peculiar smell in the factory?  It could be the smell coming from the compressor oil.

It could be the smell coming from the compressor oil.

Many pneumatic devices, including cylinders and solenoid valves, are used in production equipment.

The compressed air from the power source of this type of Air Compressor is mainly "exhausted" to the production site through the solenoid valve. The air compressed by the refueling compressor contains the peculiar smell emitted by the compressor oil.

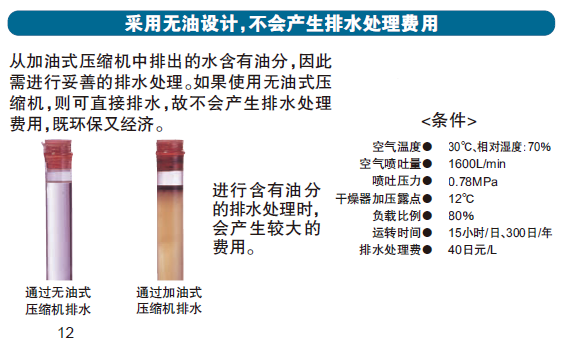

3. Are you troubled by drainage?

This is an issue closely related to cost control and environmental protection.

The water discharged by the refueling compressor contains oil, and this oil-containing liquid needs to be properly treated.

1) Properly handle

Oil removal with drainage tank

Dispose of as industrial waste

2) Relevant regulations

"Water Pollution Prevention Act"

Marine Pollution Prevention Act

"Soil Pollution Countermeasures Act"

"Sewer Act"

Laws related to waste disposal and cleaning

4. Do equipment failures occur frequently?

4. Do equipment failures occur frequently?

For example, production equipment is not running smoothly in the morning in winter.

Has your company had this experience? Production equipment is not running smoothly on winter mornings. This is caused by the solidification of the compressor oil flowing into the solenoid valve, oil cylinder and other air pressure devices under the action of low temperature at night. As the temperature inside the factory and the production equipment itself rises, the production equipment starts up again. "Morning", the most precious time of the day, is taken up by troubleshooting. Has this ever happened to your company?

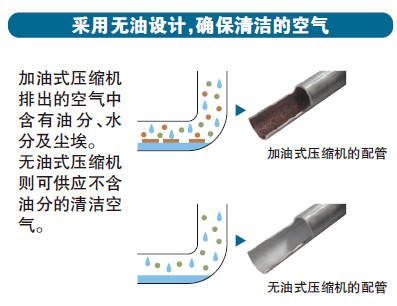

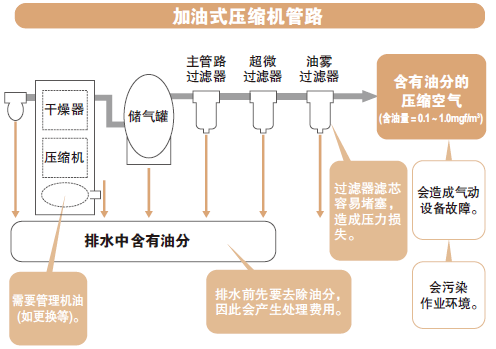

The following is the pipeline design of oil-free compressor and oil-fueled compressor

Take the pipeline design of Iwata oil-free Air Compressor as an example, and the general fuel pipeline design.

Advantages of oil-free design