活塞式空气压缩机

● 活塞式压缩机是历史悠久的一种压缩机之一, 其应用非常广泛。

● 近一二十年来,由于螺杆机在低压压缩空气工业领域有明显优势, 故活塞式压缩机使用量明显减少, 但在中高压工业领域中, 仍然有活塞式压缩机不可取代的地位。

● 优点:结构原理简单, 制造方便, 效率不低。

● 缺点:制造耗材多,运转有冲击,运行不稳定, 维修频率高。

活塞式空气压缩机的形式:

1、单作用

★单缸直立机型 ★V-形布置机型

★W-形布置机型 ★多级压缩机型

2、双作用(带十字头)

★立式布置机型 ★L-形布置机型

★V-形布置机型 ★W-形布置机型

★对称布置机型 ★卧式多级机型

螺杆式空气压缩机

● 螺杆压缩机出现于上世纪30年代,50-60年代开始技术成熟。80年代末, 90年代初,国内开始盛行。于是低压的活塞机逐渐被淘汰, 逐步使用螺杆机。

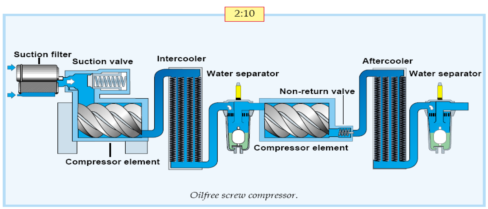

● 螺杆式空压机According to结构可分为双螺杆式和单螺杆式,According to压缩形式可分为喷油螺杆式压缩机、无油螺杆式压缩机、喷水螺杆式压缩机等多种机型,这其中又属喷油螺杆产量很大。

● 优点:结构简单紧凑, 运转平稳无冲击,运行可靠故障率低。

● 缺点:转子技术含量高, 制造难度大。

1、单螺杆和双螺杆的对比

| 名称 | 单螺杆机 | 双螺杆机 |

| 市场地位及占有率 | 螺杆空压机市场仅约占2%,生产厂家较少。 | 约占98%,占绝对主导地位。 |

| 理论上 | 原理比较专业,受力均衡。但实际上,由于无专用设备,目前无适合压缩机高温、高压、长时间、耐磨的星轮片材料。 | 转子间始终保持5~6丝间隙,不会接触,不会磨损 |

| 发展史 | 在60年代发明,日本试制。但目前由于目前加工条件和没有合适的主机材料,故生产厂家较少,市场占有率也比较低。 | 已发展有百年历史。1878年发明,1930年~1945年投放市场。 |

| 力平衡 | 螺杆受的径向力和轴向力,在设计上受力平衡。 | 双螺杆机转子在运转时会受到一定的径向力和轴向力。 |

| 加工设备 | 国内厂家没有专用的加工设备。转子只能用通用的数控机床加工,性能与精度得不到保证。 | The rotor is processed by a special rotor Grinder, and the industrial equipment is mature, which ensures the product performance. |

| reliability | Because the star wheel is in contact with the screw, the material of the star wheel is still weak, and the strength of the material is not enough, so it needs to be replaced regularly. Every time the star wheel is replaced, the accuracy cannot be guaranteed, which will lead to a gradual decline in machine efficiency. | Six sets of imported bearings are now used with a design life of 100,000 hours. The host has no wearing parts, and the trouble-free operation can reach 40,000 to 80,000 hours. |

| displacement | With the replacement of the star wheel, the installation accuracy will gradually decrease compared with the original one, and the air volume of the main engine will gradually decrease. | The rotors do not touch and do not wear out. The gas volume of the old and new machines is stable and unchanged. |

| Summarize | The theory of the product is professional, but it is still in the stage of experimental development, and its meshing line, star wheel material wear resistance and processing technology need to be improved. | Mature products have been recognized and accepted by the market, with stable performance and reliable quality. |

2. Comparison of oil-injected and oil-free screw units

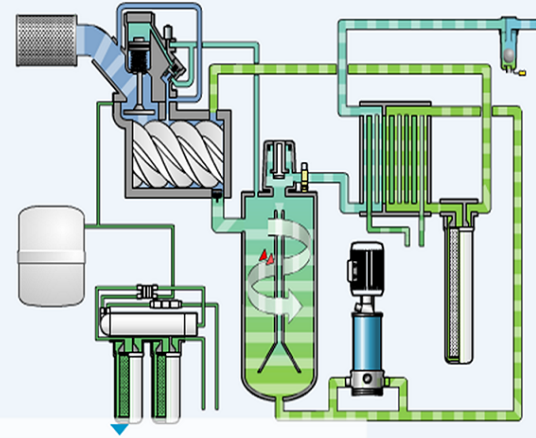

3. Water spray screw compressor

centrifugal Air Compressor

In a centrifugal compressor, the increase in gas pressure is brought by the high-speed rotating impeller to the high speed of the gas, and flows outward along the radial direction under the action of centrifugal force, and then passes through a fixed ring called a diffuser. The flow channel and the volute convert the velocity energy into pressure energy, that is, firstly make the gas obtain a certain velocity, and then let it slow down, so that the energy of the gas is changed, and the pressure of the gas is increased.

Therefore, the centrifugal compressor relies on the transformation of energy, and the pressure that the gas can increase after each stage of the impeller is limited. When the compression ratio is large, multiple impellers and multiple compression stages are required.

Features of centrifugal compressors:

1) The centrifugal compressor has a large gas volume, a simple and compact structure, light weight, small unit size, and a small footprint.

2) The operation is balanced, the operation is reliable, the operation rate is high, and the friction parts are few, so the required amount of spare parts is small, and the maintenance cost and personnel are few.

3) In the chemical process, the centrifugal compressor can achieve an absolutely oil-free compression process for the compressed medium.

However, centrifugal compressors also have some disadvantages.

1) Centrifugal compressors are currently not suitable for occasions where the gas volume is too small and the pressure ratio is too high.

2) The stable working area of the centrifugal compressor is narrow, and its gas volume adjustment is more convenient, but its economy is poor.

3) At present, the efficiency of centrifugal compressors is generally lower than that of piston compressors.