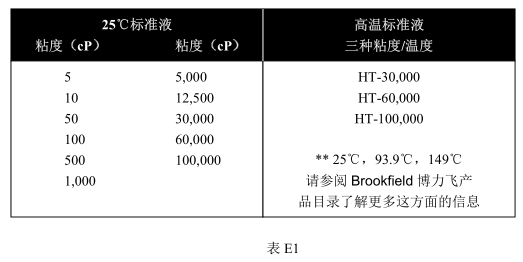

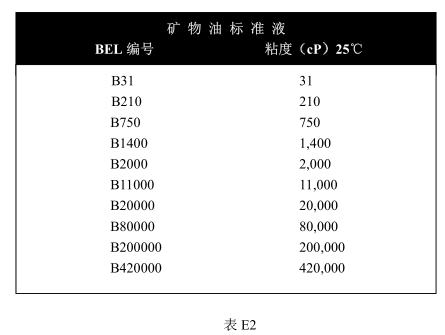

The accuracy of the viscometer can be determined by using Brookfield's viscosity standard fluid. The standard fluid is a Newtonian fluid, and its viscosity value is measured at 25°C. Please refer to Table E1 and Table E2 for the viscosities of various standard fluids. The container for the standard solution with a viscosity less than 30000cP is a 600ml low-profile beaker with an effective volume of 500ml. For the standard solution with a viscosity greater than or equal to 30000cP, directly use the container containing the standard solution. The inner diameter of the standard container is 3.25 (8.25cm) and the height is 4.75 (12.1cm). Note that a container larger than the standard beaker can be used, but it is not recommended. A container smaller than a standard beaker.

Calibration temperature: within ±0.1°C of the temperature on the label of the standard solution.

Inspection conditions: After the viscometer is installed, the temperature of the Water Bath is stable at the inspection temperature. For LV and RV series viscometers, protective legs are required.

Calibration method for LV, RV, HA, HB viscometers using standard spindles

1) Immerse the container containing the standard solution in a Water Bath.

2) Lower the viscometer to the measuring position.

3) Install the rotor. For disc rotors, prevent air bubbles from adhering to the rotor.

4) The whole set of equipment is kept warm for at least 1 hour and stirred regularly.

5) After 1 hour, measure the current temperature, if it is within ±0.1°C of the set temperature, start measuring and record the viscosity.

value

6) If the viscometer works normally, the measured viscosity value should fall within the allowable error range.

Calibration methods for viscometers using small sample adapters

1) Connect the water inlet/outlet of the water jacket to the Water Bath, set and stabilize the temperature of the Water Bath, and add an appropriate amount of standard solution into the sample container.

2) Put the sample holder into the water jacket.

3) Insert the rotor and connect the rotor to the DV-I+ viscometer using the joint extension rod.

4) Keep the temperature constant for a period of time so that the temperature of the viscosity standard liquid, the sample container and the rotor reaches the test temperature.

5) Start to measure and record the viscosity value.

Calibration method of viscometer using constant temperature heater Thermosel

When using a constant temperature heater, first set and stabilize the test temperature in the controller

1) Add an appropriate amount of HT standard solution into the HT-2 sample container.

2) Put the sample container into the constant temperature heater.

3) Insert the spindle Connect the spindle to the DV-I+ viscometer using the joint extension rod.

4) Keep the temperature constant for a period of time so that the temperature of the viscosity standard liquid sample holder and the rotor reaches the test temperature.

5) Start to measure and record the viscosity value.

Calibration method of viscometer using UL ultra-low viscosity adapter

1) Connect the water inlet/outlet of the water jacket to the Water Bath, set and stabilize the temperature of the Water Bath, and add an appropriate amount of standard solution into the sample container.

2) Insert the spindle and connect the spindle to the viscometer using the joint extension rod.

3) Fix the sample holder on the installation groove.

4) Lower the viscometer and immerse the sample container in a Water Bath or install a water jacket.

5) Keep the temperature constant for a period of time so that the temperature of the viscosity standard liquid sample container and the rotor reaches the test temperature.

6) Start to measure and record the viscosity value.

Calibration method of viscometer using lifting stand

For viscometers that use lifting brackets and T-shaped rotors, first remove the T-shaped rotors and install standard rotors (LV: #1-#4, RV: #1-#7). The method is the same as calibrating a viscometer using a standard spindle. T-spindles cannot be used to test viscometers.

Calibration method of viscometer using screw adapter

1) Immerse the container containing the standard solution in a Water Bath.

2) Install the rotor, put on the outer cylinder SA-1Y, and fix the outer cylinder on the viscometer.

3) Lower the viscometer to the measuring position, and let the motor rotate at a speed of 50RPM or 60RPM until the standard liquid overflows the outer cylinder.

4) Preheat the whole machine for at least 60 minutes, and start the motor to stir regularly.

5) After 1 hour, measure the current temperature, if it is within ±0.1°C of the set temperature, start measuring and record the viscosity value.

6) If the viscometer works normally, the measured viscosity value should fall within the allowable error range.

Calibration method of cone and plate viscometer

1) Set the gap between the cone rotor and the "plate".

2) Connect the water inlet/outlet of the sample cup to the Water Bath, set and maintain the temperature of the Water Bath.

3) Find out the required sample volume for the current rotor.

4) Select a standard solution with a viscosity in the range of 10% to 100% of the maximum measured value. When the viscosity value is greater than 5000cP, please choose mineral oil standard fluid instead of silicone oil standard fluid. For the specified spindle and rotational speed, the viscosity value of the standard fluid should be as close as possible to the maximum measured value of the viscometer under the combination.

5) Remove the sample cup, inject an appropriate amount of standard solution, and wait 10 minutes for the temperature of the two to reach the same level.

6) Install the sample cup and wait at least 15 minutes for the temperature to reach a consistent level.

7) Start to measure and record the viscosity value.