There are many methods for testing coating adhesion, which can be roughly classified into two categories: qualitative testing and quantitative testing. Qualitative detection methods include file method, bending method, grinding method, etc. The test results are generally judged by experience, and there are no specific parameter values; quantitative detection methods include compression method, stretching method, pressing method, scratch method, ultrasonic method, etc. An effective method for detecting coating adhesion should meet three basic conditions: a. The coating separates from the substrate and failure occurs at the interface; b. The mechanical model is simple, and the mechanical parameters directly related to the interface performance can be obtained. The test value is sensitive to the interface state and has nothing to do with other non-interface factors such as coating and substrate properties; c. In line with the working conditions, that is, the separation of the coating on the interface is completed in a long period of time, not a one-time damage.

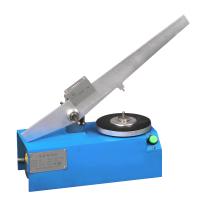

The wear-resistant coatings currently used on fuel systems mainly include WC /C, CrN and DLC. In terms of high-pressure common rail systems, as the injection pressure increases, the proportion of diamond-like coatings is increasing. For hard, good adhesion coatings such as wear-resistant DLC coatings, the detection methods for the bonding force are mainly the indentation method and the scratch method. Among them, the indentation method can generally be divided into three types: the side substrate indentation method, the interface indentation method and the coating surface indentation method. The substrate side indentation method is to place the indenter on the substrate with a certain distance from the interface on the side of the sample for continuous loading to crack the coating; the interface indentation method is to directly press the indenter on the interface to crack the interface; the surface Indentation involves pressing an indenter directly into the surface of the coating, thereby causing damage to the coating adjacent to the edge of the indentation. Due to the very small contact area between the indenter and the coating, the stress concentration inside and at the interface of the coating is high, and it is difficult to determine the starting point of coating failure. At the same time, for coatings with high bonding force or low hardness, the bonding force cannot be measured because the coating is not easily damaged and does not cause interfacial peeling. The scratch method is simple, intuitive and quantifiable, and it is a widely used method so far. In this study, the scratch method was used to detect the binding force.

For more details, please refer to the full text of "Detection and Evaluation Method of Bonding Force Between Coating and Substrate" (Ding Wang, Qian Chuang, Chen Yaodong, Wang Chunhua, Meng Feng)