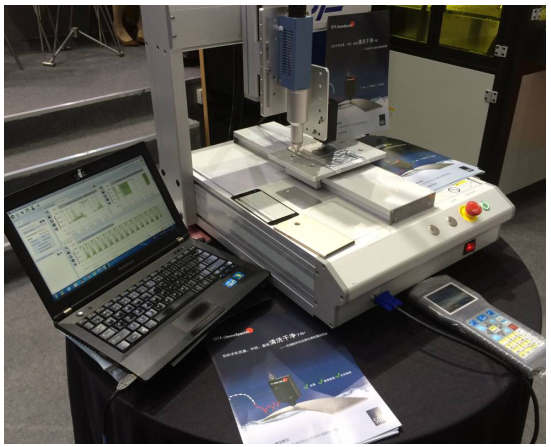

During the production process of mobile phone parts, there are often residues of organic substances such as grease, oil, wax, fingerprints, and dust on the surface of the parts. Before coating, printing, spraying, bonding, welding, PVD and other processes, effective cleaning is required to ensure the quality of subsequent processes. Of course, different cleaning methods have different cleaning effects. In addition to some commonly used physical and chemical methods, a high-tech cleaning technology has emerged and gradually matured - plasma cleaning. The plasma cleaning machine uses gas as the cleaning medium. During operation, the plasma in the cleaning chamber gently scours the surface of the object to be cleaned, and the organic pollutants can be effectively cleaned in a short period of time. At the same time, the pollutants are sucked away by the Vacuum Pump. The cleaning degree reaches the molecular level, because the cleaning medium is air, so it effectively avoids the secondary pollution of the cleaned object caused by the liquid cleaning medium.

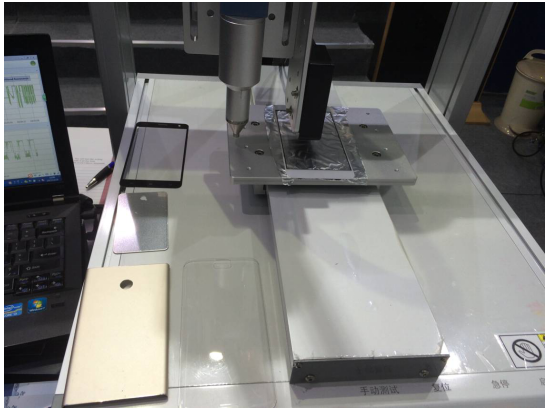

In order to verify the effect of the plasma cleaning machine, we use alcohol, ultrasonic cleaning machine and plasma cleaning machine to clean the metal, glass back cover and glass cover of the mobile phone. The results are as follows. For the evaluation of the degree of cleanliness, the surface cleanliness system SITA CI developed by the German SITA company is used. It is an instrument that quantifies the surface pollutants of metals, ceramics, glass and other materials through fluorescence detection technology. RFU value (Relative Fluorescence Units) indicate the level of cleanliness. RFU is the relative fluorescence intensity value. The larger the RFU value, the higher the residual pollutant content on the surface of the part.

*During the following test, because the ambient light was not blocked, the ambient light caused some basic values for the test readings (the readings increased by about 20RFU as a whole).

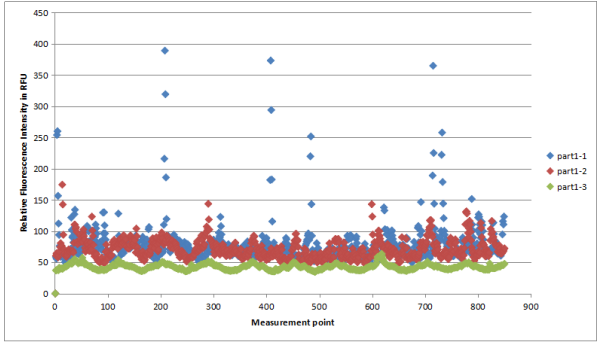

test one

Sample: 1 piece of mobile phone aluminum back cover,

Before cleaning ----- blue result

After scrubbing with alcohol ----- red result

After 2 seconds of plasma cleaning machine cleaning ------ green result

It can be seen from the result chart that the surface of the uncleaned sample has a higher degree of contamination, up to 400RFU; the sample after alcohol cleaning has a maximum RFU value of 175, with an average value of 70RFU; the sample treated with a plasma cleaner has the lowest RFU value, at Between 30-60.

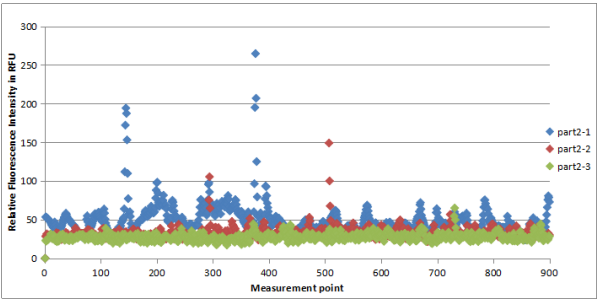

test two

Sample: 1 piece of mobile phone glass back cover

Before cleaning ------ blue result

Ultrasonic cleaning machine cleaning for 5 minutes ----- red result

Plasma cleaning for 2 seconds ----- green result

It can be seen from the above results that the surface of the uncleaned sample is more polluted, and the maximum RFU value reaches 270RFU. The average RFU value of the sample after ultrasonic cleaning is 40, and the RFU of a few points that have not been cleaned is about 150; the sample after plasma cleaning Cleanliness is better.

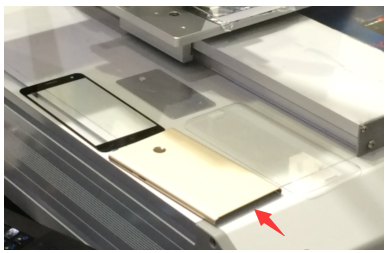

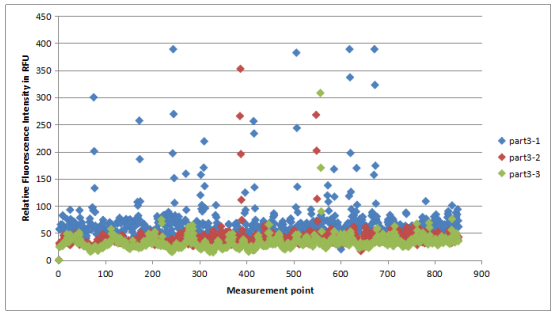

test three

Sample: a glass cover plate with white edges

Before cleaning -------- blue result

Ultrasonic cleaning for 5 minutes---red result

Plasma cleaning for 2 seconds -------- green result

It can be seen from the above results that the contamination of the untreated sample is serious; the surface cleanliness of the sample treated with the ultrasonic cleaner is improved, but some points are still not cleaned enough. The sample treated with the plasma cleaner is the cleanest and has the lowest RFU value.

Through the above experimental data, it can be seen that the plasma cleaning technology has achieved a more detailed and higher level of cleaning. Plasma cleaners and their cleaning technology have been widely used in fields that require fine cleaning levels, such as optics, electronic components, machinery, aerospace, and polymer industries, and are an important technology to improve product quality.

If you need to do quantitative experiments on the cleaning degree of your products, or verify the cleaning ability, efficiency and stability of your cleaning equipment, you can fill in the free test application form at the link below, and our engineers will contact you for testing and issue a professional Report http://jc.hjunkel.com/bmqjd.asp