Magnetic thickness measurement method for galvanized coating

The thickness of the galvanized layer is measured with a galvanized layer Thickness Gauge. The test method is carried out according to the requirements of GB/T4956 "Magnetic Method for Measuring the Thickness of Non-Magnetic Coating Layers on Magnetic Steel Substrates". This thickness measurement test is a non-destructive test and is most suitable for online quality control in hot-dip galvanizing production. The hot-dip galvanizing thickness Thickness Gauge is easy to carry and very convenient to use outdoors away from the laboratory.

During measurement, at least 5 measurement points are taken to measure the thickness in each basic measurement surface not less than 10cm2, and the arithmetic average value of all measurement points in the basic measurement surface is taken as the local thickness of the galvanized layer on the basic measurement surface.

The average thickness of the galvanized layer on all basic measuring surfaces of each sample should not be lower than the corresponding provisions in the standard. If the sample is composed of steel of different thicknesses, the thickness of the galvanized layer in each thickness part should meet the corresponding thickness requirements in the standard. The thickness of hot-dip galvanized layers can be measured quickly and easily with magnetic Thickness Gauges. For reliable measurements, these magnetic Thickness Gauges are calibrated with a non-magnetic standard check sheet of known thickness and operate in accordance with the manufacturer's instruction manual.

A common type of magnetic Thickness Gauge is electronic. Its principle is: after the separation distance between the magnetic probe head of the magnetic Thickness Gauge and the plated steel substrate changes, the magnetic flux between them will also change. A magnetic sensor with temperature compensation in the Thickness Gauge measures the change of the magnetic flux, and the detection signal is amplified by the electronic circuit and converted into a galvanized layer thickness value for display.

The typical accuracy of electronic magnetic Thickness Gauges is ± 5.

Another type of magnetic Thickness Gauge is magnetically balanced. The Thickness Gauge is placed close to the hot-dip galvanized workpiece, so that the end of the magnet is in vertical contact with the surface of the galvanized layer. The attraction of the magnet to the substrate depends on the thickness of the galvanized layer. Slowly rotate the scale ring. When the tension of the spring connected to the magnet just exceeds the attraction between the magnet and the galvanized sample substrate, the end of the magnet is disengaged from the surface of the galvanized layer, and the rotation of the scale ring is stopped immediately. The end of the magnet is out of contact with the surface of the galvanized layer, which is displayed by the indicator, and the operator can also hear and feel it. The thickness of the galvanized layer corresponding to the spring tension has been calibrated on the scale ring and can be read directly in um. The advantage of this type of instrument is that the thickness of the galvanized layer at any position is deliberately measured, and the thickness measurement accuracy is usually ± 10% of the reading.

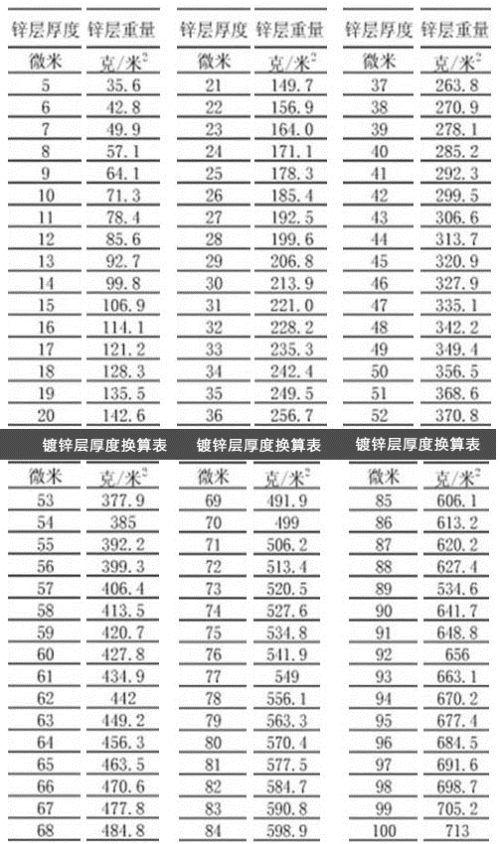

When we measure the thickness of the galvanized layer, we often have to worry about the difference between the Thickness Gauge unit (um micron) and our commonly used unit (gram/square meter), so is there a formula that can be easily converted? The answer is definitely yes. We offer two conversion solutions for customers to choose from:

1. Calculate the thickness of the galvanized layer through the company

M = 7.14 * H um

That is: how many grams per square meter, divided by 7.14, can be obtained by converting the thickness of hot-dip galvanizing.

2. Check the thickness of the galvanized layer through the conversion comparison table

| 锌层厚度与锌层重量换算表 | ||||

| 锌层重量(g/㎡) | 锌层厚度(μm) | 锌层重量(g/㎡) | 锌层厚度(μm) | |

| 35.6 | 5 | 377.9 | 53 | |

| 42.8 | 6 | 385 | 54 | |

| 49.9 | 7 | 392.2 | 55 | |

| 57.1 | 8 | 399.3 | 56 | |

| 64.1 | 9 | 406.4 | 57 | |

| 71.3 | 10 | 413.5 | 58 | |

| 78.4 | 11 | 420.7 | 59 | |

| 85.6 | 12 | 427.8 | 60 | |

| 92.7 | 13 | 434.9 | 61 | |

| 99.8 | 14 | 442 | 62 | |

| 106.9 | 15 | 449.2 | 63 | |

| 114.1 | 16 | 456.3 | 64 | |

| 121.2 | 17 | 463.5 | 65 | |

| 128.3 | 18 | 470.6 | 66 | |

| 135.5 | 19 | 477.8 | 67 | |

| 142.6 | 20 | 484.8 | 68 | |

| 147.9 | 21 | 491.9 | 69 | |

| 156.9 | 22 | 499 | 70 | |

| 164 | 23 | 506.2 | 71 | |

| 171.1 | 24 | 513.4 | 72 | |

| 178.3 | 25 | 520.5 | 73 | |

| 185.4 | 26 | 527.6 | 74 | |

| 192.5 | 27 | 534.8 | 75 | |

| 199.6 | 28 | 541.9 | 76 | |

| 206.8 | 29 | 549 | 77 | |

| 213.9 | 30 | 556.1 | 78 | |

| 221 | 31 | 563.3 | 79 | |

| 228.2 | 32 | 570.4 | 80 | |

| 235.3 | 33 | 577.5 | 81 | |

| 242.4 | 34 | 584.7 | 82 | |

| 249.5 | 35 | 590.8 | 83 | |

| 256.7 | 36 | 598.9 | 84 | |

| 263.8 | 37 | 606.1 | 85 | |

| 270.9 | 38 | 613.2 | 86 | |

| 278.1 | 39 | 620.2 | 87 | |

| 285.2 | 40 | 627.4 | 88 | |

| 292.3 | 41 | 634.6 | 89 | |

| 299.5 | 42 | 641.7 | 90 | |

| 306.6 | 43 | 648.8 | 91 | |

| 313.7 | 44 | 656 | 92 | |

| 320.9 | 45 | 663.1 | 93 | |

| 327.9 | 46 | 670.2 | 94 | |

| 335.1 | 47 | 677.4 | 95 | |

| 342.2 | 48 | 684.5 | 96 | |

| 349.4 | 49 | 691.6 | 97 | |

| 356.5 | 50 | 698.7 | 98 | |

| 368.6 | 51 | 705.2 | 99 | |

| 370.8 | 52 | 713 | 100 | |