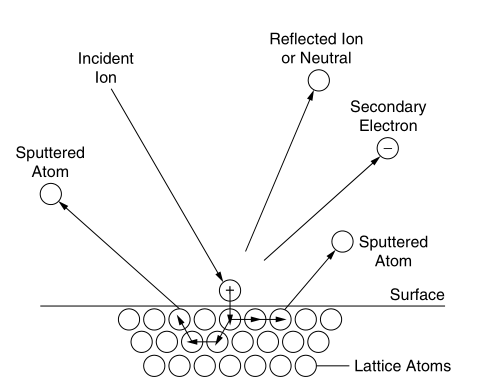

Sputtering is a momentum transfer process. When a particle hits a surface, the course of the collision depends on the energy of the incident particle, the angle of incidence, the binding energy of the surface atoms, and the mass of the colliding particle. (figure 1)

In sputtering, the incident particles are usually ions because they can be accelerated by an applied electric potential. If they strike the surface with less than about 5 electron volts of kinetic energy, they may be reflected or absorbed at the surface. Surface damage occurs when the kinetic energy exceeds the surface atomic binding energy, when atoms are forced into new lattice positions. At the energy of the incident ions exceeds a threshold, typically 10 to 30 eV, atoms can be dislodged or sputtered from the surface. At normal incidence, multiple internal collisions are required, but at lower angles sputtered atoms can be produced directly. These sputtered atoms and ions can condense on the substrate to form a thin film coating.

High-energy ion bombardment is usually achieved by a low-voltage process of the glow discharge type, in which case the basic process configuration of a diode is shown in Figure 31.2. The vacuum chamber is equipped with the target material (cathode), the source of the coating material and the substrate to be coated. To dissipate the considerable heat generated in the target during sputtering, it is usually a water-cooled metal (copper) backing plate attached with solder or conductive epoxy. The target can also directly cool the water for greater cooling capacity. The chamber is evacuated and then backfilled with an inert gas, usually argon, at a pressure of 10–3 to 10–1 Torr. *Potential applied between target (cathode) and substrate holder (anode). This creates a low voltage glow discharge or plasma between the two electrodes. A grounded dark space shield is used to prevent discharges from forming in undesirable areas. In this type of DC glow discharge, the current is carried by electrons collected by the anode from the plasma, and the positive ions accelerate the plasma toward the target. A continuous supply of additional ions and electrons is required if the discharge is to be sustained. Some of the ions striking the target surface generate secondary electrons which are accelerated by the cathode potential. These electrons, with energies close to the applied potential, enter the plasma to ionize the gas atoms, generating the additional ions and electrons necessary for the sustaining discharge.

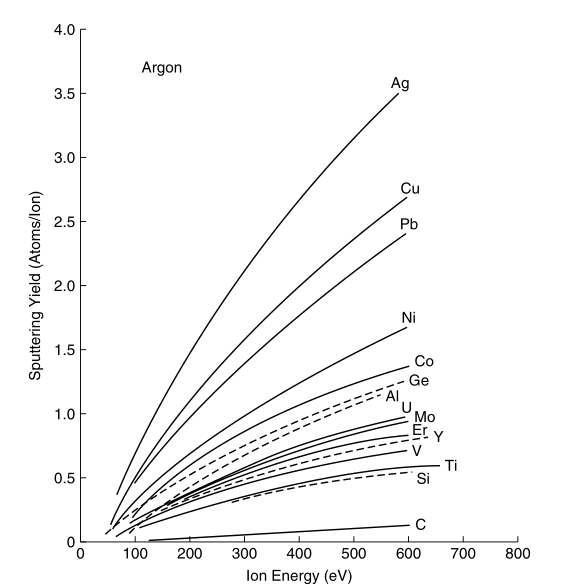

The relative deposition rates of different materials depend largely on the sputtering of different materials, the sputtering rate (Fig. 31.3), defined as the number of target atoms ejected per incident particle. Sputtering yields are target dependent, with silver yielding the highest yields and generally increasing with incident ion energy and mass.