For some aqueous solution products, it is often necessary to control the pH value to ensure quality, such as beer production, water quality testing, etc., pH value control is a very important task. So how to use the pH meter, how to maintain the pH meter, and how to solve the problem of the pH meter? The following is a detailed description of these three aspects.

How to operate the pH meter

The correct use of the sound meter needs to pay attention to the following aspects:

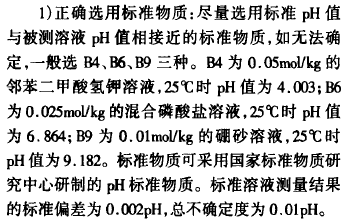

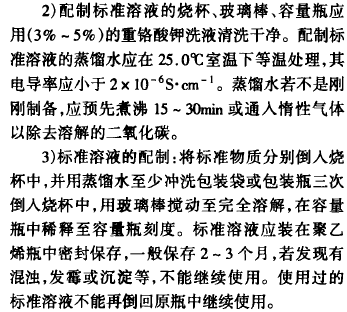

1. Selection of standard substances and correct preparation and storage of standard solutions

The pH meter should be properly calibrated professionally before use

Generally, a two-point calibration method should be used. Pour an appropriate amount of standard solution from the standard solution bottle into the beaker, measure the temperature of the solution with a mercury thermometer, and input the temperature into the "manual compensation temperature" setting of the pH meter. Find out the state value of the standard solution at this temperature.

Attention should be paid during the calibration process: Generally, the standard solution with serial number B6 is used as the first point. When calibrating the second point, if the measured solution is acidic, use B4 solution; if the measured solution is alkaline, use B9 solution. Gently shake the beaker , After the displayed value of the pH meter is stable, press the "calibration" button to adjust the slope regulator, so that the displayed value is consistent with the pH value of the pH standard solution. After rinsing the electrode with distilled water, do not wipe the electrode when using filter paper water to blot the moisture outside the electrode to prevent polarization and slow response. Do not use the electrode as a stirrer. When measuring the pH value of the tested solution, the temperature compensator should be adjusted to make the temperature of the tested solution consistent.

PH meter maintenance measures

1) The pH meter should be kept clean to prevent the electrode socket from being polluted, and the short wire should be connected to it when not in use to prevent dust from entering and affecting the measurement accuracy;

2) Since the panel of the DEITA320pH meter is made of polycarbonate, it is easily interfered by organic solvents such as toluene, xylene, and ketones. Once such solutions are splashed, wipe them off immediately.

Maintenance of glass electrodes

1) When the glass electrode is used for the first time or reused after long-term storage, it should be soaked in distilled water or 0.1mol/L hydrochloric acid for more than 24 hours;

2) The glass electrode should not be used for long-term measurement in strong acidic or alkaline solutions, should not be used at high temperature, and should not be in contact with dehydration media such as absolute ethanol, so as to avoid its surface dehydration affecting its performance;

3) The glass film of the glass bulb of the glass electrode is extremely thin and easy to break. Do not contact it with hard objects. Check the glass film for cracks, bubbles or spots before use;

4) When measuring a solution with a high viscosity, the measurement time should be shortened as much as possible to avoid contamination of the electrode, and the electrode should be cleaned carefully immediately after use;

5) Make sure that the electrode is always filled with the correct filling solution and placed vertically, and any filling solution attached or solidified on the outside of the electrode should be rinsed with distilled water in time;

6) If the slope of the electrode drops or the response is slow, use absorbent cotton dipped in acetone or soapy water to wipe off the surface dirt, and then soak the electrode head in 0.1M HCl overnight. The electrode can also be immersed in: 0.1M HCl+10% pepsin to remove protein precipitates. Each unit can be cleaned 1 to 3 times a month according to the frequency of use;

7) If the electrode is not used for a long time, the electrode should be stored in an electrode storage bottle filled with soaking solution or a rubber protective sleeve filled with soaking solution.

The correct preparation method of PH soaking solution: Take a PH4.00 buffer (250ml) bag, dissolve it in 250ml pure water, add 56 grams of analytically pure KCI, heat appropriately, and stir until completely dissolved.

Causes of Common Faults of PH Meter and Their Solutions

1. The clicked correction slope is out of range

Cause of failure: The electrodes are dirty and need to be cleaned.

Solution: Select the mV mode and put the electrode into the pH7 buffer solution, there should be 0±35mV, otherwise the electrode should be cleaned. Then perform two-point calibration. If the slope is >105%, check whether the calibration buffer is correct; if the slope is 0%-105%, the electrode is in good condition; if the slope is 85%-90%, the electrode needs to be cleaned; if the slope is <85% This indicates that the electrode needs maintenance or replacement.

2. The reading is unstable

Causes of failure: ①There are air bubbles in the electrode liquid interface; ②The electrode reference liquid level is too low; ③The electrode interface is dirty.

Solutions: ① Shake the pH meter lightly to remove air bubbles at the liquid interface; ② Supplement an appropriate amount of internal reference solution; ③ Clean or replace the electrode interface.

3. Slow response

Causes of failure: ① The ion concentration of the sample is low; ② The electrode is dirty.

Solutions: ①Wait until the reaction balance is reached; ②Clean the electrode or replace the electrode according to the above steps.

4. Incorrect reading

Causes of failure: ①The calibration buffer used is incorrect; ②The buffer used has exceeded the expiration date or is contaminated; ③The electric meter is faulty.

Solutions: ① Replace the correct buffer solution; ② Reconfigure the buffer solution; ③ If the new electrode is still ineffective, the instrument should be sent to the local metrology department for repair.